Ink Pressure Issue on Vandercook SP20

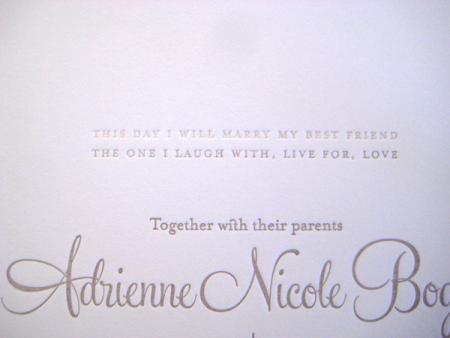

I recently purchased an Vandercook SP20 and am having issues with the ink pressure. The part of the plate that sits closest to the feed board barely puts any ink on the paper. See image as an example.

Does anyone know what is causing this problem and how I can fix it.

Thanks

Emily

printing_issue.jpg

It looks to me that the roller are too low and removing the ink.

You need to raise the rollers and bring them slowly down to just touch the type.

I found this information that might help from the Vandercook website:

http://vandercookpress.info/vanderblog/articles/lange-adj/

Hi Emily,

Congrats on your new Vandercook. Once you get rolling you will love it!!

I would suggest posting this on Paul Maxon’s Vandercook site mentioned in Aaron’s post prior to trying to adjust your cylinder carriage bearings. I would also suggest adding as many details as you can think of in terms of your situation. e.g. plate type, base type, ink, packing, roller condition, etc. Also, as Aaron points out you should look at your roller height as a good first step to trouble shooting. If you do not have a roller gauge … get one! They can be purchased from NA Graphics.

Lord, do not play with your impression bearing adjustments unless you KNOW that is a problem.

First test then roller settings using a roller setting gauge (the “lollipop”). Check them on “print” on both the print stroke (taking the carriage all the way to the end of the bed, no short-rolling should be done on an SP model) and the return stroke. If the rollers are sitting at different heights going forward and backward, then the bearings need to be tuned, specifically the bearings at the front of the carriage, over the bed bearings, until the rollers stay at inking level forwards and backwards.

Also check your packing and make sure there is consistent packing under this first line of type as under the script. Your rollers can be inking properly, however, if the packing is light it won’t make proper contact with the sheet.

Casey

Inky Lips Letterpress

Emily

This isn’t uncommon. Likely the bearing adjustments are off. I have the adjustments on one of my presses set for full coverage of the bed, which means I actually sacrifice the ability to print 1-3/8 inches at the top of the sheet.

So you have two choices. Configure your printing sheets in this regard and trim later or have the bearings adjusted. I’d opt for the former. Unless, of course, you know of a whip smart press mechanic.

Or, it could be as simple a problem as Casey suggests. Check and replace your packing, always.

Gerald

http://BielerPress.blogspot.com

Hi,

Thanks fro responding. I do have a roller gauge (“lollipop” – I like that term) and the rollers were at the correct height while the carriage was at the end for the bed. Didn’t check the height while traveling backwards though. Will do that next. The packing seemed to be fine.

It seems like the cylinder gear rack has been adjusted. See the picture below. There are thin pieces of metal under the rack. Is this common?

Gerald, for this run I had to configure my printing sheet and trimmed later, but of course would rather not do that.

Thanks again,

Emily

IMG_0248.jpg

The shims under the gear rack are quite normal. Many Vandercook assembly instructions included “shim to fit” in many places.

Is the impression the same over all of the type?

It might be the base (I’m assuming you are using a photopolymer) or it might be that the bed has some wear at that point.

Which way is the roller rolling over the type. Parallel with it or perpendicular to it. Generally you would rather have it run perpendicular. If you are running it parallel the rollers wouldn’t seem like they would be the problem as you are clearly getting good inking also.

Emily, one problem that can happen is in time the rollers get old and need replaced. They can shrink, or expand in dia. They start applying ink unevenly. But i’d check for possible adjustments to clear up your problem. In offset printing it’s very simple to check, you can pull a bead and it would show the roller pressure on the plate.