Brazed platen and uneven pressure

Hi everyone, after getting a mechanic to come and fix my press, because the pressure knobs were not giving me uniform pressure, and him not being able to fix it.

I was suspicious as of why the platen had paint on it.

And so I got a bit of paint remover. Stripped the paint off the platen, and to my surprise I found a crack on the corner which had been brazed.

The people who sold me the press, swear that it doesn’t affect print uniformity.

Can anyone confirm?

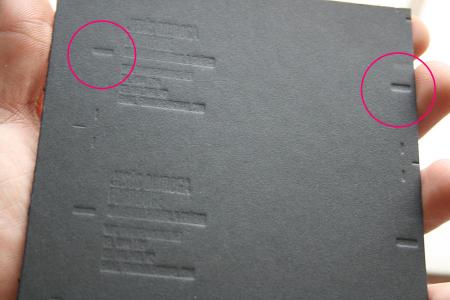

Also, I’m posting a photo of what I’m trying to print, you can definitely see that there’s more pressure on one side than the other.

I’d like to do just a bit deeper than kiss impression, not really this mess that’s going on here.

We weren’t able to reduce the pressure, it jumps from this much pressure to no pressure at all.

I’ve checked my aluminum base and photopolymer with a micrometer and they read out perfect type high on each side.

It’s a 10x15 C&P Craftsman, with aluminum base, and KF95 plates.

Thanks for your time and comments.

Maquina32.jpg

IMG_045633.jpg

Two quick questions-

Are you certain your base isn’t skewed in the lockup? Meaning, one side could be lifted up ever so slightly- it’s important it be planed down on all sides.

Second- have you ever leveled the platen out or checked all the corners (or an approximation) with type high materials (hopefully four strong squares)? It’ll involve locking up four pieces into a chase relatively close to the corners and packing it out to .065 (or whatever your undercut/packing setting should be), then putting feelerstock or a piece of thin tympan into the press, closing it on impression and checking each square for tension? This is how I discovered my C&P needed some attention, and was able to work the impression bolts until it balanced out.

There’s also a nifty gadget made by John Falstrom which may help you.

It might affect impression on that corner if it were not level with the rest of the platen (i.e., FLAT). More likely, if whatever cracked (broke?) the platen also affected the adjustment mechanism, you might not be parallel. Close your press and measure the gap between bed and platen. If the bed is FLAT, you should be able to adjust to parallel.

had a 10x15 c&p with the same corner welded, if it is done right it should be ok, you very seldom use that far down in the corner of the press.

Hi, thanks for your answers, guys.

The base is not skewed. I’ve checked and double checked, several times have I removed it and locked it up again.

I locked up some big metal type (48 points I think it was) on all four corners, and just by shining a light I was able to figure out that the bottom of the platen does not give more neither less pressure when turning it’s pressure knob.

The top side works for sure.

It does look like the top is parallel.

The bottom of the platen seems to be the main problem.

Why is my pressure knob not working. The mechanic came in and made sure it was working, but I’ve verified that in fact this knob does nothing as of right now.

Thanks for your further input!

Whatever broke the bottom corner also mangled something in the adjustment mechanism - if you disassemble it, I’ll bet something like a rod or connecting shaft is broken.

Alright.. fair enough.. I’ll take that lead.. The problem is I wouldn’t know how to do it.

And the good mechanic is out of town mingled in a political campaign.. The not so good one is the one I have at hand.

:(

I’ll see if he can do it.