Uneven Impression on a C&P 10x15

I am attempting to print a large pattern (5x7) using a polymer plate on my C&P 10x15.

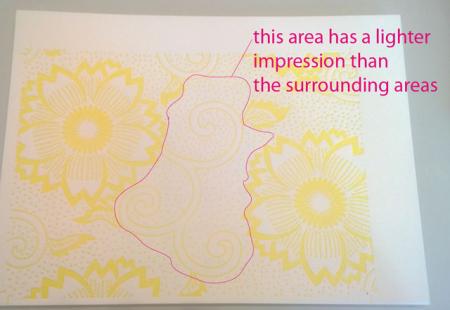

The edges of the print have a deeper impression than the center, and I would like for it to be even across the page.

I have thought about using packing to build up the center but since it is a pattern there really isn’t an easy way to create a shape that will fill the area of the lighter impression.

I have been reading other message board postings but most seem to be about needing to level the platen and mine is level.

This has happened on a few occasions and it only seems to be when I am printing a large print area or a large solid area.

Any advice is appreciated.

Screen-Shot-2013-10-29-at-12.04.jpg

Have you tried interlay? Your problem is not uncommon on larger hard-pattern plates. Underlay or interlay usually cures the situation. And, rather than using scissors to cut a suitable shape, tear the pattern to shape. That approach eliminates the sharp paper edge delineation and/or also allows a quick overlay on the tympan to be used. Mind you, you are using poly. :o)

Makeready, part of every printer’s balanced breakfast:

http://www.hevanet.com/ashiogi/makeready.htm

Thank you for your responses. I ended up doing an interlay and underlay. However I find that the parts I build up start effecting the other parts around it. These larger plates definitely require more make ready!

What is the polymer plate mounted on? It should be mounted on a solid hard wood block and not plywood. For very fussy work I have used a solid lead mount block and machined it perfectly flat using a type high gage. It was poured in a mould using waste lead and planed with a carpenter’s plane until the disered height was attained. The bottom of the mould would be perfectly flat and the top would be machined then turned over. The polymer would then be attached with double sided tape. Check the bed to see if it is flat with a 100 years of pounding you never know. Best of luck Dave

One little extra check, with an engineers straight edge or an accurate steel rule verify both the Platen AND The Bed for overall surface accuracy, Horizontally, Vertically and Diagonally, i.e. no visible daylight or Air Mail paper type gaps!!!

By implication consider regrind/resurface either/both as last resort???

Pye in the sky!! Impossible, Unheard of, O M G etc etc???

Check out with one of your well read, (good ole Yankee Buddies perhaps) the following ***one will/may verify that Vertical Meihle,s were/are ground with, CYLINDER/BED either or both, slightly convex to rectify this very situation!!!

This against the background of, the Wall thickness of the Cylinder and the Very Substantial web,s under the bed.

It would appear that Meihle, Goss, Dexter factored this in a long time ago??

Could, possibly C & P after many, many, years of faithful service, (and now being expected to cope with this, SMASH the image into the Platen regardless) be crying in pain or are the operators?? expecting too much!!

Check out my V/M offerings and please correct me ON Line if I am incorrect.