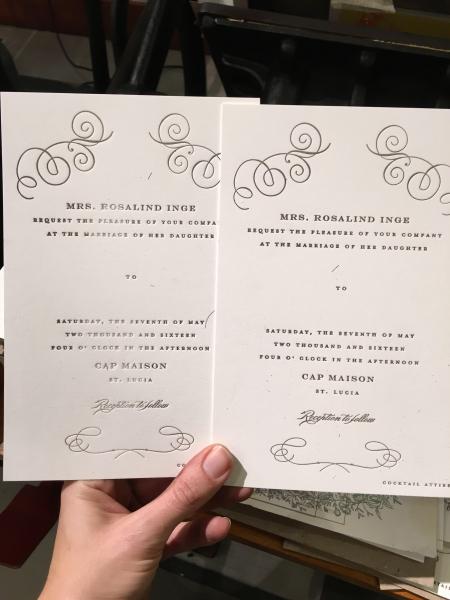

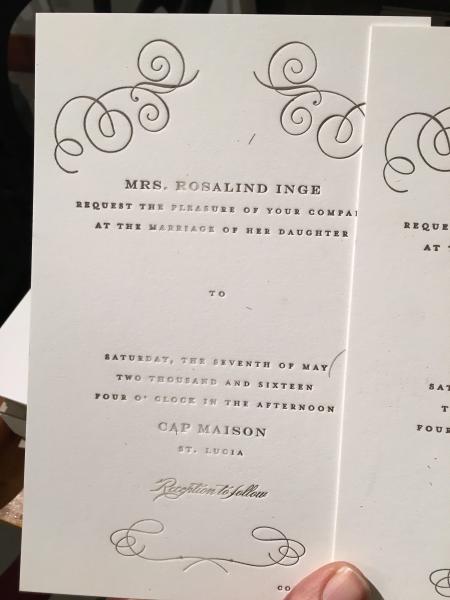

uneven ink coverage

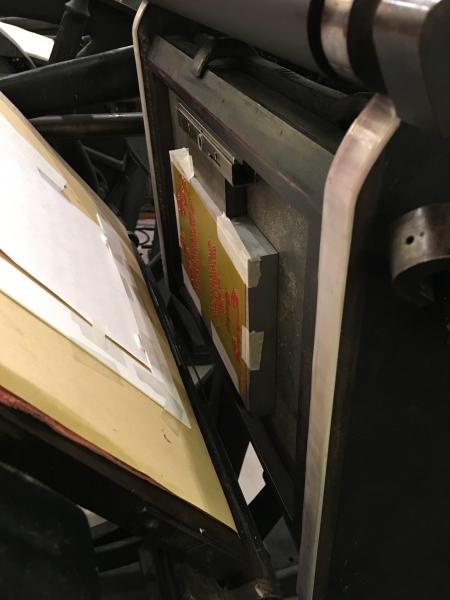

hi all! I’ve been working on setting up a c&p 10x15. it’s in pristine condition by appearance but needed a lot of work. i’m on the final stages of leveling the platen. I put art in 4 corners, got that print even and everything looked good. I put in a trial invitation plate to see how it looked with full text. I need to play with the level a bit more but for some reason the print keeps changing - sometimes there’s more ink, sometimes the ink goes away all together in the print. the rails are raised to deep relief level using rail tape. I have brand new rubber rollers so there’s no pits or flat sides. i’m confused as to what to do from here. any tips would be appreciated!

unnamed19J71FGR.jpg

unnamedGJPIQIN1.jpg

unnamedTGTKJG11.jpg

unnamed.jpg

hi all! follow up comment. I’ve received some helpful info but wanted to put it out there that I’ve been running presses for 10 years. i’m looking for more advanced advice than bits about how to put on ink. I am in no way an expert of course, but looking to dig a little deeper! thanks!

Uhm, 10 years.

I hope that you have come to realize you must be a little smarter than the press. Not a lot, but some. This so you can help the machine do the work it was designed to do.

It looks like the rollers are not applying the ink to the form correctly, or the form is rejecting the ink. Poly sometimes acts a bit funny for no known reason.

Not likely, but start fresh. Clean the form with alcohol. It dries quickly. Relock the form and make sure the chase is

dead flat against the imposing stone. Put chase in press and ink the form by turning the press by hand. Inspect the rollers to see if there is an imprint on the rollers where the form has taken ink from the rollers. Inspect the rollers to see if ink coverage is uniform across the width. Remove chase and examine the inked form carefully at the stone. A magnifying glass may be helpful.

The form must be inked correctly before you can go any further. If not uniformly inked, you have a roller or truck or rail problem. New rollers are no guarantee if the trucks or rails are wrong.

If the form is inked correctly, proceed to print and hope that cleaning and relocking the form solved the problem.

If the problem recurs, turn the rollers end for end and try again. If the poorly inked stripe changes position, you have learned something. You have information.

Think and understand how the press is supposed to work.

It wants to do a good job, but often needs some help from you.

Get some ink on your shirt.

What happens when you rotate the form 90º? If the new print looks identical then there’s unevenness in your base & plate combo.

If the light inking is in the same spot relative to the press, when you probably have a high spot on your rails.

Is it just the tape thats holding your plate onto the base? That could be an issue.

I think the problem is with the Poly Plate. I tried using Poly Plates, if they are cleaned correctly they act funny. At times I thought it was the press are ink. So, I removed the form and put Linotype slugs in a lock up and it printed great. The type was clean and the ink dark. So, I knew it wasn’t my press or ink.

So, I made a metal plate from some artwork I used on the Poly Plate, the metal plate also printed clean and well inked.

Looking at the photo posted, I am not impressed with the product.

You mentioned you used rail tape to improve the relief level. Sometimes with poly plates the rollers skid a bit instead of roll. Even if it is only the last form over the plate that skids, it acts like a squeegee and the result is a light streak. If you look with a good loop you can sometimes see streaks in the light area. Rotating the form will either fix it or confirm the problem. If your roller pressure is a little heavy, or you are not using very soft rollers the form can raise the rollers a little, reducing the “grip” of the trucks on the rails, allowing the rollers to skid.

Copperwillow, it does look like possibly a combination of rollers a bit low/roller height uneven. Could the rail tape be failing to achieve type height, due perhaps to the rails not being level, as Daniel Heff suggests? Or a low spot on a roller—I sure hope not, as you say they’re new. But it does happen.

If it’s not too late to get a new plate made, there’s a grammatical error: Mrs. Rosalind Inge requests (singular) not request (plural).

Thinking outside the box, (or trying?)

As the forme/image is laid landscape, with a very DODGY lock up, surely the chances of the (New) rollers traversing the Ink Disc and hitting the same points EVERY pass, must be fairly remote?

A little powdered Rosin on the *Taped* Trucks, and/or the Bearer Rails will prove or disprove slippage.!

Suggest the problem is elsewhere.

Even against the back ground of the originally stated,

*contact in ALL 4 corners,*

has/have the BED, the PLATEN, the Mounting Base, even the image (over 100% to view) been checked for perfect flatness. via Steel Rule (preferably engineers or printers equivalent) to prove NO line of sight under.?

*It`s in pristine appearance*

seems to over look, possibly with the Age involved, that it is almost certain, that for over 100 years, and by default, the Bed & Platen, to a lesser extent, has to have had a beating, right in the middle in both planes.?

Little experiment, maybe, with just one or two sheets of decent stock (NOT the regurgitated blotting Paper as above,) and with modest progressive make ready ON the packing, pull just a few impressions, may prove OR disprove lack of or presence of Ink.

One more tiny prove/disprove etc, 5 finger *Dabs* of ink, on the back of the mounting block, chase placed in Machine, one or two impressions will verify, or otherwise that the base is at fault…>Effectively, Engineers Blue test.>

Apologies for rubbish,! but may prompt further thinking.

Thank you for this helpful thread, I’ve been ‘enjoying’ similar mysterious behavior by my rollers on a 10x15 old style. [I found the post about inconsistent inking of polymer interesting. Did not know this.] I’m hoping what I found recently on my press might help you:

out of curiosity, I recently measured the diameter of each of my 6 trucks with a micrometer and found the following dimensions (inches): 1.678 (x2), 1.74 (x2), 1.7 and 1.74. Of course, I can’t claim to have perfectly, smoothly taped rails (a work in progress,) but I am in the process of sourcing replacement trucks, since I find that only the roller with the smallest pair of trucks inks the form consistently, and generally the second roller is not inking to potential.

When I read your post, I also wondered if by chance one of your rollers might have been inadvertently stored on a flat surface, or otherwise become flat on one side? Wishing you success. I hope you will post your findings.