Heidelberg Windmill 10 x 15 speed of the feeder table

I have some questions on the use of Heidelberg Windmill 10 x 15 Black ball.

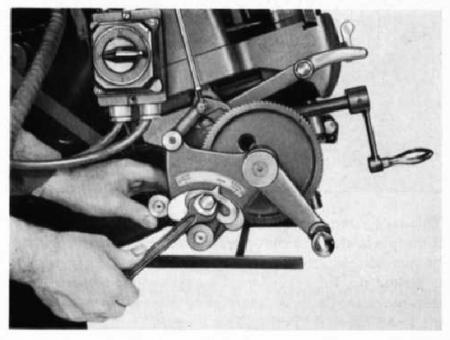

How to slow down the rising speed of the feeder table ?

I according to the manual page 71, intends to adjust the elevator speed.

I configured the device does not seem the same, what is the adjustment which part?

Or am i missing parts?

1484012534418.jpg

1614.JPG

I this is a 10 x 15 yep

P1090301.JPG

P1090300.JPG

Ho…..Different.

Because my model is older?

So can I adjust the elevator speed?

I believe on that models arrangement. It would be the rod that is attached to your part that pushes the gear “paw” teeth. Being that’s possibly your only adjustment, I would only make micro adjustments. I would follow what it says for adjusting that rod in the manual you have. Just a wild guess.

I have also Heidelberg OHT (10x15) and GT (13x18)

The 10x15 there is no under-recovery option (The rod need to set the correct height), the 13x18’s have.

The picture P1090301.JPG, P1090300.JPG is a GT 13x18

litograf95

If I have GT on the Floor I think I would have noticed, this Pics are from a 56 Tiegel 10*15

Blast from the past,? which may be completely irrelevant - if so apologies… . Follows thus:- having several times repaired the same section and components as above, eventually the pile height adjustment system *runs out of steam* in that the pawl TIP wears to such a point that replacement is required BUT a quick fix is obtained by Filing/Re-profiling the tip, short of new part??? . .

This only works up to limited amount, BECAUSE as the pawl describes an ARC in relation to the ratchet wheel the TIP disengages too soon, could this be part of the problem???

We have Brazed/Bronze welded, (built up and re-profiled by hand) the original tip as a *Jury Rig* keep it running, and even resorted to hanging a 36 Point quad on the pawl to persuade it to hang in a few “Thou” longer.

Perhaps turn the M/c. over by hand and watch the movement especially when the actuating rod is nearing the extent of its Arc & Push, because it (pawl and ratchet wheel) are what they are, the pawl can-not maintain 100% contact during its entire stroke.!!!

Again!! Apologies if this be irrelevant and/or rubbish, but may prompt the “Real Deal” Mick. Jan. 2017

You might try putting a light weight spring between the bolt for the pawl and the bolt for adjusting the pile height.

This works on a red ball but perhaps the black ball doesn’t have the paper thickness adjustment. As a quick test to see if this will work attach and elastic band to the pawl bolt then try to find a stationary object for the bottom hook up. If it works try the spring.