Lawson 38” Paper Cutter

Hi,

We are feeling a little lonely out here because it is rare to come across a sibling or a cousin to our Lawson 38” paper cutter that we sort of accidentally acquired (wasn’t looking for something this humongous)… So we made a video on YouTube hoping to find others with the same…

We were dumb enough to inject copious amount of grease into a Zerk fitting on the main flywheel shaft, only to find out immediately afterward that the viscosity of it was just too much for the 2HP motor to pull to its operating speed in time before the contactor’s safety kicked in.

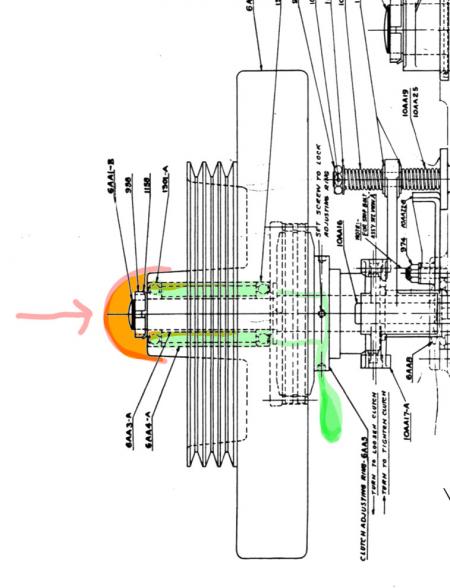

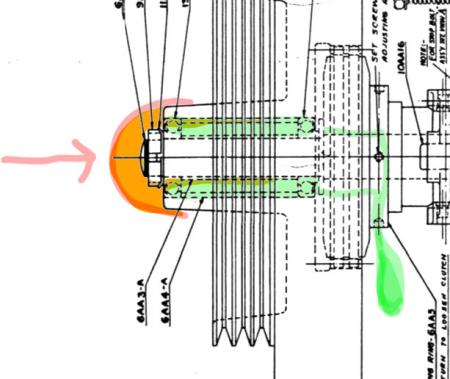

We were able to purge the grease much like the “plastic over the commode” plunging method. We bagged the outside end of the shaft with a thick plastic (with some extra spacing to let the injected motor oil to sit in [orange] and manually pressed against the barrier [pink] to push the oil which pushed the grease [green] out from the other end.

The flywheel is supposedly 350LBS so we really didn’t want to remove it to clean the shaft…

… and it is finally in working order.

It was touch-and-go for a few weeks because we don’t know what we are doing…

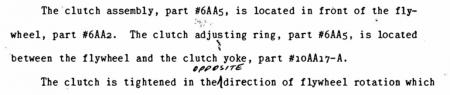

RTFM, you may say, but as you can see from a pic from the manual, we just weren’t quite sure what to believe. The typed manual or the hand-written notes over it… There are many instances like this. (see the 3rd pic).

But all looks good now.

This is as OSHA unfriendly as an industrial machine can get? Of course it is designed so you have to use two hands to operate - so as not to chomp chomp your limbs….

Our next project for Mathilde here is to fix the hinges on the lower cover door so it will be a tad more safer to operate.

Thanks for watching :)

bagOverShaft.jpg

take2.jpg

Screenshot 2019-10-18 18.29.04.jpg

Here’s a quick animation on how the grease was purged…

http://www.outside.center/wp-content/uploads/2019/10/purge-gif.gif