Stuck Throw-off lever

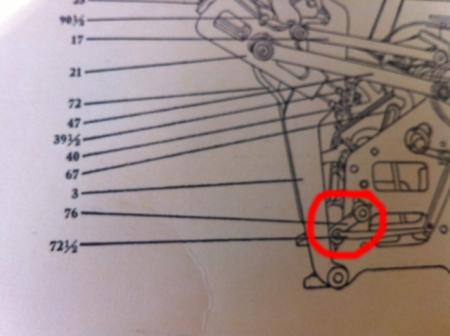

I have just moved my C&P 10x15 press into my garage and am having trouble releasing the throw-off lever. The press sat unused in a print shop for about 15 years, so I am not sure if gunk has solidified, thus causing the lever to stick. It seems to be stuck at part 76 - the Outer Arm to the Throw-off.

I am also attaching photos of the suspected cause of the problem. My question: Is there a way to solve this issue without disassembling the throw-off lever and its connection to the press? Would heating the area in an attempt to “melt” the crud work??

I am anxious to print, but can’t until this is resolved…

Any suggestions are much appreciated!

Thank you!

Part 76.jpg

photo 2.jpg

photo 3.JPG

Just posted the topic and realized the center photo is rotated 90 degrees to the left. sorry…

Lashing of WD40 or whatever penetrating oil you can buy . leave for a few hours and then work it till free .Using heat is a drastic fix only for a last resort as you need to heat the casting not the shaft and torch will wreck the paint !

i would not heat anything, if the press has sat for years it might be wise to spray it with wd40 everywhere you should oil it, this should loosen any frozen parts, then give it a good oiling and you should be all set.

In addition to penetrating oil I’d clean out the oil holes and let the oil soak through; there is an oil hole right there. Maybe give the ends of the shaft a few gentle taps with a hammer.

A mix of half acetone and half Automatic Transmission Fluid makes a very effective penetrating lubricant for frozen parts.

It may be worth it to disconnect the various linkage pieces and verify that each moves independently in order to positively identify the location of your problem. These few pieces are among the easiest to disassemble and reassemble.

If for instance the offset shaft, which the throw off system ultimately rotates in order to distance the base from the platen thus avoiding impression, is offering resistance then it will keep every other piece in the series from budging as well.

Thank you so much for your insightful responses. It is indeed the offset shaft that bwletterpress mentioned. I have sprayed the life out of the shaft, etc with WD-40 and have taken a rubber mallet and banged away at part no. 76 with no luck. It is as stuck as ever. I am now trying to figure out a Plan B. If anyone has any suggestions, I am all ears!! Thank you again for your help!

it might be part no. 72, when you go on impression the large shaft that part 72 connects to has to rotate, this might be your problem.

That is unfortunate news since taking the offset shaft out requires disconnecting the top of the base from the main frame by removing the side arms—not to mention the roller arms, but those should be comparatively easy. If you do this, be very careful to secure said base to the frame with the press closed since you don’t want that weight falling back on you or anything else for that matter when you are working on getting said shaft out. Make sure you don’t damage the shaft even more in removal (mushrooming where the side arms slide on by hitting it with a hammer, which it seems the previous owner may have done to ours) but it will probably be quite hard to remove.

http://briarpress.org/20162

We actually had the exact same problem. It wasn’t ENTIRELY seized and I was able to get it into the impression position—we just wanted to see a print—and then we wanted to print more and got busy. So we’ve lived with the press stuck in impression for nearly two years.

At one point recently while I was working on the press and had some things disassembled we actually left the throw off linkage disconnected out of laziness and tried running the press and found that the impressions kept getting lighter and lighter—it turns out because when the base closed against the platen the offset shaft was rotating slightly allowing the base to be pushed away…if that makes sense. I hooked up the linkage again and while turning the press over managed to pull it back into the impression position again. So clearly it isn’t totally seized…it just doesn’t rotate freely enough to easily use the throw off, without breaking something or giving me a hernia.

Of all the things that could be wrong, this was pretty minor for us. We bought a Hern treadle since the motor was shot and thus have easy control to stop the press in the event of a misfeed if the paper is really worth the effort. It does prevent us from doing multiple inkings, but that hasn’t been enough of an annoyance to justify taking the whole press majorly out of commission again.

If you can get this shaft out and check which areas are too tight, built up, or damaged then you should be able to have those sections milled, cleaned, or repaired to solve the issue.

Speaking from experience, there is no better way to understand how these wonderful machines work than taking them apart and putting them back together again…so maybe you and the press will be better off through this trial.

Where are you located?

B Wletterpress.

Succinctly put and so very true ,I was taught and made to learn how the presses worked right down to little parts ,mainly due to my instructors being ex military printers that in their day were printing on the backs of huge wagons that the sidesloweredto form a work are and each wagon had two heidelberg cylinders on the back powered by generators , these men had to build as they had to know their onions as we say . they were taught at the heidelberg plant, i believe the british army still require that you can do the engineering as well as the printing . That said you learn so you can see what is not right ,the advantages are endless and saves many thousands or sheckels !

Having no thow off on my little swift (j Haddon 6x5) has never been a problem, if i dont think i will have the next sheet ready to change i let it wreck the sheet thats in the press ! I dont chase the platen in for a few pence ! Having no throw off restricts you in speed as you cannot have a miss and chasing the platen in is ,as recently i saw on here, “suicide” . As you think you have found the shaft responsible,its back to more of the above clean holes oil with penetratin or thin oil and just keep gently coaxing back and forth and oiling and coaxing till it improves .

Problem solved! Looks like lots of WD-40 and persistence paid off. Thanks so much for your valuable input!

Congratulations! Good to hear of some success.

I am in the same boat.. my back shaft must not be turning because the saddle bracket broke when it was turned ( after sitting for 40 yrs untouched).

Guess I am going to PB Blast it like crazy and hope to free her up.

_ great advice was given above.. and to all who have tried to help me with this same problem. Lets pray for the best!!!

Use lots of heat!!!

Take a good close look at the back eccentric shaft too, because somebody may have decided to paint the press in the distant pass and put the shaft in backwards. If the shaft is stamped Chandler and Price (the NS press I worked on did) it should read right side up if standing behind the press. If the stamping is upside down, then the throw off will be backwards (forward is off, back is on. Likely you’ll have a very stiff throw off to boot.

I’m slowly reviving a 10 x 15 that somebody had painted for the Bicentennial and didn’t put it together right. It also too a tumble and bent one of the connecting arms, which created probably more problems than the upside down eccentric.