C&P Roller Height Issues

Hey letterpress peeps!

I print daily on a C&P new style 12x18”. We use a Boxcar deep relief base with deep relief plates. My rollers are a black rubber, basically new. I print on cotton stock, card stocks and handmade papers and sometimes envelopes. In all cases, I have a HUGE roller balancing issue as our press is like many where the rails are worn down with time. I have done the work using a roller gauge to dial in the inking, but as I change out plates every day, I am always fine tuning with scotch tape to make things print heavier or lighter with the ink.

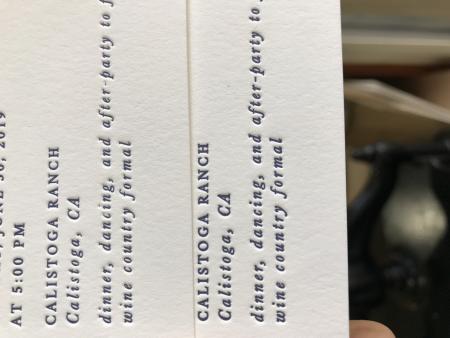

I’m attaching a picture of a symptom I see more and more often lately where I start printing with too heavy ink, and so I add a piece or two of scotch tape. After testing, I wipe off the plate, re-ink it, test print, and it’s good so I run my job, but over the course of about 50-80 impressions the roller continues to raise itself to the point where ink isn’t making contact with the plate which ruins prints because the periods or hyphens or type start to impress with no ink. So then I remove the piece or two of tape from my rail, the rollers lower that tiny amount, and the print goes great the rest of the way…sometimes. Sometimes I continue to adjust it. Strangely it doesn’t go back to the heavy state it started in, which is what prompted my adjustment, and that tells me the roller height isn’t just being effected by tape but maybe springs or friction or something?

Do plates settle, or does plate adhesive compress and lower plate height? Is my taping wrong? Is there a better tape than scotch to fine tune with? (I’ve tried banded tape and I’ve seen how that tape moves and compresses, so I won’t use that). We have a few layers of a thick plastic rail tape that seems good, and it stays put as I use scotch tape to fine tune.

I’m just at a loss. I’m wasting prints needlessly, having to reprint jobs at times, and the quality suffers as I run prints with inconsistent leveling. But if I level the rollers it never seems to work from job to job so I don’t see the point of doing that if I cannot repair or permanently repair a worn rail? Anyone got any ideas?

letterpress impression sample.jpg

C&P ROLLERS, not familiar with you machine but if you have worn tracks is there any way you could get over size trucks made and then just tape for small adjustments and as mentioned in a previous thread use aluminium tape that does not compress. Just some thoughts, good luck.

I would recommend roller bearers if your rails are worn resulting in inconsistent inking. You can do this with type high slugs or you could have some manufactured from type high wood, Delrin, or aluminum. You can probably find some online that are made of bent pieces of steel.

Simply lock the bearers up on the far sides of your chase and make sure they’re not making contact with your sheet during impression. They’ll keep the rollers at type height regardless of whatever wear may be present on your rails.

Hope this helps,

Bradley.

maintain press speed. it matters how the rollers work and impression… oil the press regularly..

Nico, For best results always run type and rule parallel to the rollers. Steel trucks perform better than MERTS.

Steel tape for the uneven rails is more stable, you can get it from Wagner Supply.

best james

Solved this same problem decades ago, usually on the humble NON High Tec, Adanas, after we ran out of the options on the Adana, for flipping the trucks 180 degress from standard clearance to the lower clearance, when the roller compound had *virtually* reached usable life span, but got a few more impressions before re-covering, perhaps the equivalent of Your Morgan expansion trucks.

We just topped the rails, NOT with incessant Tape after Tape in all manner of Low Tech. solutions, but by Making stainless STEEL slippers and bonding them to the rails, D.S.A. superglue, chemical metal, 2 pack epoxy resin, etc. etc. etc., not exactly Rocket Science then or still now.

O.K. even with 18 - 20 S.W.G. stainless steel slippers, the clearance could and was often a fraction too much, but with normal make-ready methods in mind, Litho plate or Acrylic sheets behind the forme, gave/gives excellent depth control, in the same manner as using Litho Plate or Acrylic behind Cutting, Creasing, Perforating rule(s)

Author. (C) Not copyright but re-posted for the benefit of the New devotees. i.e. to protect the bed(s) and/or the face of the platen(s) of the Vintage Machinery.

As Custodians, for the future, perhaps, Be gentle.

Good Luck. Mick.