Strange ink consistency / coverage issue HELP!

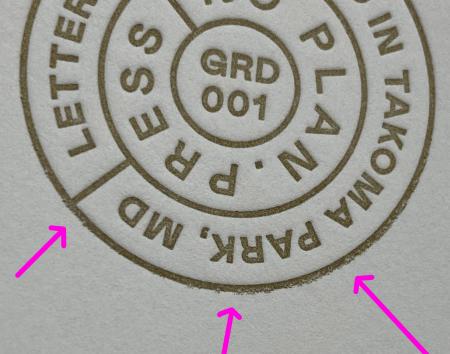

I am having an infuriating ink coverage issue on my C&P. See photos to see what I am talking about.

I was using oil-based metallic gold ink on cotton Savoy paper. There are areas where the ink is splotchy and bleeding out of the design. Here is what I know / have tried:

Packing… tried new packing.

Rotating / moving the plate

Different paper stock/weight

Less ink / More ink

Two Rollers / Three Rollers

Different boxcar base

Piece of copy paper behind boxcar base

Extra layer of tape on the rails

Flipping the rollers

More packing / Less packing

I have had this issue when using oil-based neon ink as well as rubber-based ink with lots of trans white, however this was the worst I’ve seen and nothing I did helped. The exception being rotating the plate, but that didn’t completely alleviate the issue. The spots also show up in the same place more ore less. Usually towards the bottom edge of the plate/design, although on the left and right of CONGRATS, again near the bottom of the C and S.

It is driving me CRAZY.

Help!!!

IMG_5167.jpeg

IMG_5168.jpeg

IMG_5169.jpeg

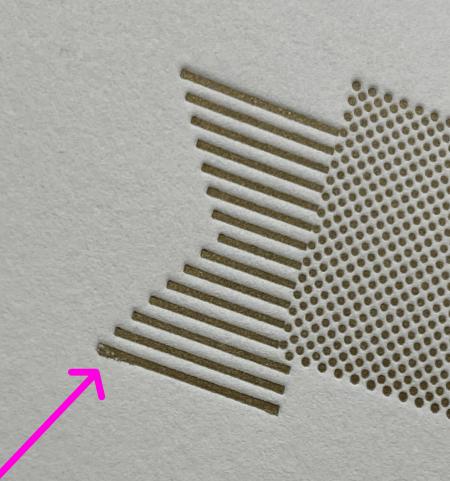

Are the trucks the same diameter as the rollers? If the rollers are larger they will skid as they contact the plate, causing ink to pile at the edges. If they are smaller they will slide across the surface and cause slurring.

Looks like sliding marks, wipe your roller rails. Also the trucks. Free of oil. Offset powder or talcum powder.

If that doesn’t help, check your rollers.

Use some roller wash.

You use a fair amount of pressure and you say the spotting shows up in the same spots when you rotate the plate. Have you checked the plate itself for damage?

For the slurring, is the stock flat? Is your tympan sheet tight? If one area of the sheet hits the plate first the plate pushes it flat to the platen and creates a sliding mark where it touched.

Thanks for these ideas… the trucks could certainly use a cleaning. They are the nylon kind. I think I got them from NA graphics. Also will be re-taping the rails.

As far as I can tell the trucks look the same diameter as the rollers… how much of a tolerance are we talking here? If its off my a hair?

I have some Easy Street and will give the rollers a good wash. Will also try to tighten up the tympan sheet… I use a piece of acetate as my top sheet. I think it gets really tight, but maybe not… the paper stock is flat.

rollers.jpg

There is no size reference here. What is the format of your press? How long is the “congrats” text? A press like that will not print evenly over the entire area of the platen, there will be fall-off around the edges. I.e.: if your press is a 6 1/2 x 10 format and you are trying to print a word that is 9 1/2 inches long, the “c” and the “s” will certainly have coverage issues, and it might manifest at 8 inches. You run into a similar issue when trying to print a large solid shape. You can correct for some of this with good make-ready, but platen presses all have that issue which is why some of the lucky folks here use cylinder presses instead of platen presses.

Also, Boxcar plates come in different thicknesses that correspond to the height of the base. If you are using a low base and a plate that is specified for the high base, you can have issues with coverage.

You should probably check your roller clearance as well. Lollipop gauges aren’t just too expensive.

I know it can be frustrating, but don’t pull your hair out. Some issues are pretty hard to track down, so it’s a matter of experimentation. Be advised that it could be a combination of things, or something that nobody here has ever seen before… though that would be pretty unusual.

Also, strive for perfection, but don’t ever actually expect it, because you will never achieve it. Even if you run your press while the moon is in the seventh house and Jupiter aligns with Mars, out of a hundred prints, you’re only going to get maybe ten near-perfect prints. If you are running multiple colors, that ratio drops to maybe one in a hundred due to registration errors and just statistical artifacts.

In other words, don’t worry, be happy!

I dont have a C&P - Try taking most of the packing out until you get no impression or print, then add back until you get an image . This should let you see if platen is level. Now add tape to the rails until the image no longer prints. Remove the tape a little at a time until the image starts to print. This should tell if your rails and rollers are parallel. In a perfect world the press should ink the plate with the same pressure on the down stroke as it does the up stroke. You might try adding tape ( a shim of sorts) to the point or above and below the point where the slurring is at to bump to the roller contact path.

Is your paper curling or flopping around at all? This looks a bit to me like the paper is touching the plate a little, then flattening out and making full contact once the press is fully closed. Not sure if this is as much of an issue on hand fed platens as it can be on auto-fed machines but might be worth looking at!

EDIT: Sorry, I see someone else said this above, I thought I’d read through but I missed it! :)

Success! I did a mini-overhaul… deep cleaned the rollers and trucks, re-taped the rails, new tympan and packing… not sure if it was one of them or all of them, but am having much better results with no slurring at all.

Thanks to everyone for your suggestions! It’s a big relief… No pun intended.