Thoughts or experience of a Haddon Swift

Hello all,

I’ve been watching you from afar gathering bits and learning, only now I’d like to ask for some advice.

An elderly printer near me is retiring, he may sell me an old treadle press of his. It’s pretty old (the owner thought anything up to 100 years), but this is what we could decipher.

It’s made by John Haddon and Company of London, and is called The Swift.

The inside chase size is approximately 7 1/2” by 11”.

That’s about it. I’ve learned that John Haddon was the head of a firm of typefounders and printers based in London. I believe he died around 1900. At least, wikipedia says his son, Alfred Haddon, an anthropologist, was around 1855-1940

I can’t find any reference to a similar press on briarpress, but the following entry in the souvenir program of the 1905 Annual Convention of International Typographical Union, held in Toronto, says:

Swift Platen

THE LATEST AND MOST UP-TO-DATE SMALL JOB PLATEN PRESS

ON THE MARKET, STRONGLY BUILT, LIGHT, EASY RUNNING,

HIGH SPEED, EASY FEED, IMPRESSION ADJUSTER AND THROW-

OFF. FOR FOOT OR POWER, v. v •%. MADE IN THREE SIZES :

No. 1 — 8 x5 inside chase No. 2 — 9 x6 inside chase

No. 3 — I I x71/2 inside chase

Both these presses are made in England, and they do not discredit British engineering skill.

JOHN HADDON & CO.

Sole Proprietors of the Caxton Type Foundry

124 YORK STREET, TORONTO

——————-

That’s as much as I can discover. It’s good to know the press did not discredit British engineering skill, but if anyone can help me out with thoughts about the quality of the press, perhaps a rough stab at it’s value, and any comments on the condition I’d be grateful.

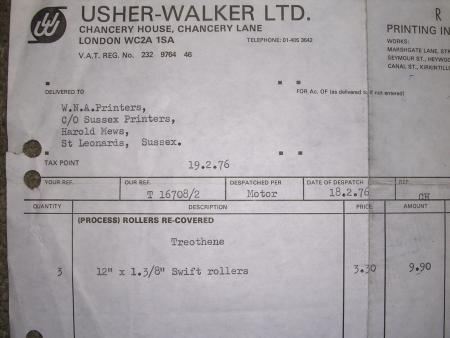

I know he’s used vinylith rollers from the green slime covering various parts and visible on the ink disk in the picture below. The material is discussed in this post:

http://www.briarpress.org/7700

and sounds a right pain.

Thanks all,

Ben.

the haddon swift for briarpress.jpg

Roller Invoice for briarpress.jpg

platen and chase hinge for briarpress.jpg

ink disk and feeder for briarpress.jpg

cogs etc for briarpress.jpg

Hi Ben,

I have some information on the Haddon platen. I have a catalogue from 1925 which features the Swift. It has a solid flywheel by then, so I suspect your press is earlier than this. Make sure that when you treadle the press (with the help of a few drops of oil) that it turns over smoothly and without bumps or clanks (which can mean wear in the bearings or cog teeth).

Also small treadles are not rare in England so don’t pay too much for a machine that will cost you money to get right. Also bear in mind the rollers will not be cheap to reclothe.

But if it is cheap enough it will be a rewarding project to restore and use.

Please email me through the site if you want to know more (I’m in the UK too)

Jeremy