Heidelberg Guide Movement

I’m having trouble with movement of the guide bar on my Heidelberg (1962) — until this morning the guide bar wasn’t pulling up towards the platen as it closed.

Then thanks to the thread here:

http://www.briarpress.org/15708

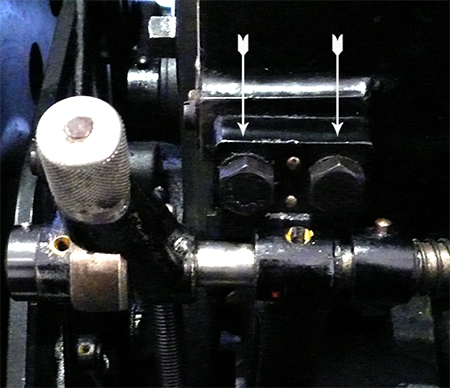

and in particular Jim Chase’s comments posted below, I was able to loosen the hex bolts shown in the picture and engage the knurled knob while pulling up on the guide bar. Cycling the press manually I see that the guide bar is moving as it presumably should (though I will need to adjust it a bit higher, I believe on the bar itself?).

The problem however is that when I retighten the hex bolts the guide bar stops moving — I can’t imagine it’s a good idea to run the press with loose bolts, so am wondering what else I should be looking for?

And should I be retightening those bolts when the press is open, closed, or somewhere in between?

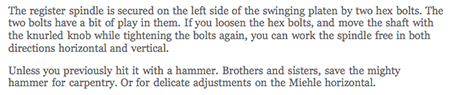

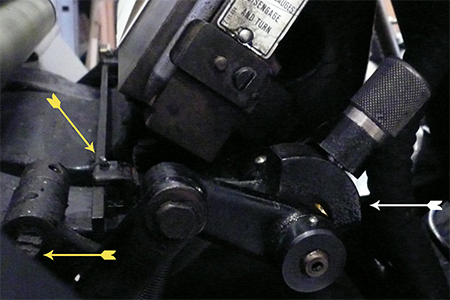

I’ve also attached a side view of the guide assembly — the knurled knob doesn’t extend all the way back to the white arrow as it appears it should on page 53 of the manual.

The yellow arrows point to broken bolts (the guide bar bolt broke yesterday as I tried to loosen it, and I think it can be easily replaced). Is the break at bottom left somehow influencing the movement of the guide bar?

Thanks so much for any insights you can offer.

knob_bolts.jpg

hexbolts.jpg

sideview.jpg

had the same problem with my heidleburg, the gauge would not come up the same each time, it would work for a while then not quite come up far enough. i found a oil hole behind the fly wheel i had missed for about 20 years, now it works fine. good luck dick g.

Hi Dick,

Thanks for the tip — Can you tell me where it is?

We’ve made some progress here, able to play with the knurled knob enough to force the movement down the ramp at right and raise the guides, but can’t seem to free the spindle enough to cause it to move without a fair amount of force. It’s clearly gunked up and cleaning the inside seems impossible but I’m working on it.

It seems the cam with knob attached should be kicking back further than it is as the press closes — any connections we should be looking at?

Thanks again, Elisabeth

Hi Elizabeth,

Its been some 15years since I handled a windmill, but if my memory serves me correctly I agree with Dick’s comments.

Unfortunately I cannot find any photo to show the part and the often-missed oil hole, but if you follow the linkage of the guide bar back towards the flywheel housing you will find a lever which rocks up & down and in the centre is an oil nipple. This is the one.

The way I used to remedy any stiffness is to get the oil-gun and drain the oil from it and refill with kerosene, then at the end of the day squirt this kerosene into the oil nipple until you can see it coming out of the bearing; leave overnight, then in the morning reload your oil-gun with oil, and force the oil into the nipple until you can see oil coming out of the bearing.

Your problem should now be solved, but remember to give this part a regular oiling.

Hi Bern,

Thanks very much — I’ve got that oiled well and the register spindle is still stuck.

I’ve been manually cycling the press and then, when the platen is about 5” from the chase, give a shove to the knurled knob — the lay bar raises to within a hair of the platen and the roller on the “ramp” on the delivery side extends out to the right edge.

I admittedly don’t have a clear understanding of how spring compression works but it seems the spring (0235) requires a huge amount of force to be compressed (thereby allowing the bar to slide).

It’s that final lateral movement and kick back of the cam / knob that won’t budge when the motor’s running.

The Heidelberg parts manual on the Boxcar site is missing page 28, so I can’t identify any part between 0228 and 0248. Still it looks like it’s all there.

Help!

Thanks again, Elisabeth

Just a thought—

I wonder if the shaft has been bent slightly, or something else is causing the shaft to bind. I’m thinking that you might try loosening the two bolts holding the shaft a bit and try shimming one side of the casting or block through which the shaft runs, say with a half-point copper or even a piece of paper. Retighten and see if it changes the alignment for better or worse. I’m not quite clear on whether you can raise the guides by hand or not, but I’d be careful about running the press under power until you are certain that the binding is corrected.

You are pulling back/up on the knurled knob to raise the guide bar by hand are you not?, in order to disengage the knob from the arc into which it is latched.

Brian

Thanks Brian, I’ll try that — the guide bar is raising and lowering when the knurled knob is engaged with the pin dropping in halfway down the arc. That bit works, insofar as the guide bar is raising and lowering whether I’m manually cycling the press or running the motor but only when the hex bolts are loosened.

The problem is that it’s not raising far enough, and there’s a considerable gap between the pins and guides and the platen — way too much wiggle room.

I’ve figured out that the little roller on the delivery side should be traveling down that ramp to allow for the final push up and lateral movement of the lay bar.

So I’ve been able to push the knob at a point just before the press closes to force the lay bar up, but can’t replicate it when the press is running (don’t think it would be smart to stick my hand in there either). After a day of cleaning with a toothbrush and some degreasing and re-oiling it’s moving more fluidly but still needs some muscle behind it.

The hex bolts and bracket assembly all look to be in good shape to me but I realize if it’s off by a hair that’ll be enough to prevent the mechanism from working.

One other thing I’ve noticed is that the lay bar itself isn’t bent or crooked but also doesn’t run perfectly parallel to the platen — it runs ever so slightly farther out on the delivery side.

One other thing maybe worth mentioning: once I’ve given the knob a push to raise the bar entirely the guides move up fairly close to the platen and continue to as I cycle the press. But once I start running the motor the guides don’t appear to move up as far.

thats the same thing my press was doing, i oiled it so much it wasn’t funny. i run a job each year somewhere around 300,000 sheets, this drove me nuts, the gauges would work for a while then not come up all the way, the paper would still feed but not register each sheet, the job had numbers on it that had to be dead on and when this would happen they would be off by 6 pts. bern has a great idea (should have talked to him before) try the kerosene that should help loosen the part that is binding. i put a job for myself on the press and ran it to find the problem, like bern said follow the linkage, oil everything that mov es the gauges, it took me a while to figure it out, the parts like you described seemed to be the problem, but the actual bad guy was further away, behind the flywheel. good luck dick g.

Searching through my 80 yr memory archives, I remember we used to test the guide operation with a strip of paper placed between the cam on the main shaft and the follower on the lever that’s linked to the guides.

With the paper in place and held by the follower apply gentle tug while turning the machine over by hand.

The paper should be held for the complete cycle; if it can be withdrawn easily then there is a fault, and needs to be remedied using the kerosene method I described earlier.

Hope this helps and that my memory has not let me down, Bern.

Pearl,

There is an adjustment on the guide bar to make it parallel to the platen; an adjusting screw with a locknut at each end of the bar as shown encircled in red on my illustration.

GuideBarStop.jpg

Machinery generates vibration which are transmitted to the surroundings and can influence the manufacturing processes of other equipment and thereby have an impact on product quality.

Vibration Isolation

Such vibrations can also be a disturbing nuisance for the vicinity and for the environment, and can also lead to damages to buildings. Sylomer polyurethane elastomers are special materials designed to reduce vibration and structure-borne noise. Depending on the requirements, these materials are available in a wide range of densities, thicknesses and dimensions. Their static load capacity lies between 0.005 N/mm - 3.0 N/mm (0.5 t/m - 300 t/m ) Both the static and dynamic characteristics of these products are exactly defined, allowing the effectiveness of the elastic suspension to be calculated in advance.

You can do more research here: http://www.cyber-bridge-marine.com/Resilient-Bedding.html