platemaking, etching, galvanic

i am a metal artist with a printerest and am self appointed head of R+D at Rough Ray Press. I know i should be working on an etching or litho press, but im wondering.

ANYONE GOT GALVANIC ETCHING EXPERIENCE?

I’ve got a big sheet of copper and am planning on roughly following the instructions at http://steampunkworkshop.com/electroetch.shtml

which requires an acid-resisting image, car battery, copper sulfate and a deathwish.

my press is a vandercook no. 3 proofer.

looking for reassurance that i could get a decent relief this way or with some other acid. can i only do solid lines or will a halftone pattern hold up to the etch? would a “progressive etch” work better? i know it probably wont be deep enough for my tabletop platen press whose ink roller trucks are the wrong size, but on a more precise machine? anyone tried?

i plan on the inkjet-toner-as-resist-for-the-acid-technique (described by the steampunks) not working as well as a rubber or acrylic SCREEN PRINTED resist image.

any insight into an ink that will hold up for the necessary etch time or an acid that will etch around a screen ink? dont know why i cant find a way to relief etch a plate with a screen print resist anywhere online.

i’m a metal guy, i just don’t see why i should have to use photopolymer…

with sincerity,

-nick

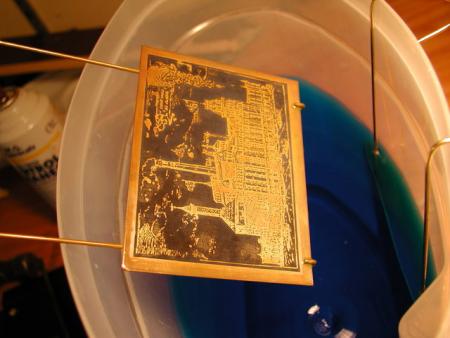

etching.jpeg

etchplate copy.jpg

Geeeze, that setup looks like something from “Marathon Man”. Get the kids out of the house before you fire that up.

Yeah, as far as the ink you should use- Don’t use ink. Why don’t you order some senefelder’s asphaltum?

Or, on this page, 3rd product down #12040

https://www.graphicchemical.com/shopdisplayproducts.asp?Search=Yes&sppp=...

It’ll be pretty thick in the container, but you can thin it with PURE TURPENTINE (NO OTHER THINNER WILL WORK WELL- No Odorless mineral spirits or any other mineral spirits- they contain water and won’t work well with asphaltum). You’ll need to clean out the screen with the same stuff. Do it outdoors or in a well ventilated area.

Once you screen-print that onto copper with a #230 mesh screen, you’ll want to heat set it to the plate for maximum durability- use a paint dryer/heat gun and do it outside with the plate on a couple of sticks to elevate it, cause solvent is gonna end up in the air.

You’ll know it’s working when the grounds turn kinda glossy and start steaming. Once they stop steaming you’re probably done. Let the plate cool and then try etching it.

Im fairly certain you’ll have results that are superior to a toner transfer or other inks.

Another friend of mine has used oil enamel screenprinting ink before as well, and he makes his own synthesizers by printing the circuits themselves. Seems he’s gotten good results though I haven’t physically examined them.

http://www.capefearpress.com/

Jennifer is great to talk to, and the site has lots of resources.

http://www.greenart.info/galvetch/notacid.htm

Cedric Green has been doing a lot of galvanic etching, might be worth a look here and google search for similar.