Quick and easy makeready.

Ok, for you purists, please don’t read this.

Quite a number of years ago I started doing my makeready by taping a sheet of translucent vellum, (UV Ultra II, Chartam), onto the tympan and pulling a proof. I would then place my paper under the translucent, line up my form, (image, type, whatever), and trace the edges of the paper to determine where it would have to lie to be in register. Then I would cut a diagonal slice about 3/4” long to put my quad guides in place. Cutting on the diagonal allows me to move the pin both left and right and in and out to perfect the positioning once I pull a proof on the actual stock.

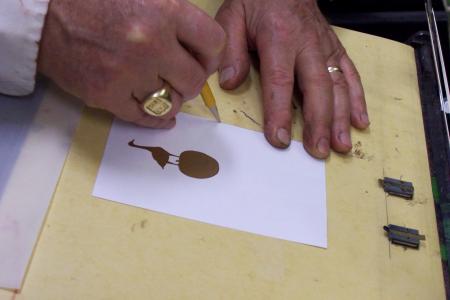

The accompanying pictures show the process. It is quite simple, quick and avoids excessive marking and cuts into the tympan.

tranlucnet poistioning 6.jpg

Additional pix

tranlucnet poistioning 6.jpg

translucnet positiong 4.jpg

translucent position 2.jpg

tranlucent position 3.jpg

That is positioning, Makeready is the Art of using thin papers to adjust for differences in the pressure of large and small type or areas to achieve even inking.

Not sure you’d get even inking that way — but you can certainly even out the impression with make-ready. Minor detail ;-)

I use a sort of similar method for positioning — a blank 8-1/2x11 sheet folded to hang over the top edge of the platen and aligned with one edge of the tympan paper, take an impression, register the press sheet over it for image position, carefully hold the press sheet in position while sliding the printed sheet out, then either mark the edges on the tympan or just place the gauge pins to the edges, and make slight adjustments if necessary after a proof on the press sheet. I’ve done it that way for almost 45 years.

Bob

Typenut,

Like I said, purists please don’t read this.

s

Setting the pins

Related to another post of mine. Different ship, different long splice.

There are few one only right ways. If it works to get the job done, it is good.

I learned to make the first impression right on the tympan paper and draw the lines for setting the pins from that impression. The tympan sheet was then washed with solvent, rubbed dry, and powdered with talcum powder. Care was taken to wipe the talcum toward the top of the platen so not to get down to the inked form and rollers.

Today I wish to use my tympan sheet as many times as possible and do not print directly upon it. I tape a piece of 20# stock on the tympan sheet and make the impression. Measurements are made and the lines for the bottom and left margins are marked with the lines extending to the tympan sheet. The 20# is removed, the lines completed on the tympan sheet, and the pins placed.

i replaced the tympan with a sheet of 80 lb coated text, when printed on it wipes clean, i run quite a few jobs before i have to change it.

One more silly one, and cheap(you can not get cheaper than nothing) virtually every fridge and freezer has rubber seals around the doors, inside which are beautiful lengths of magnetic strip very pliable very soft snapped with 2 fingers or cut to any length, and stuck to the platen to obtain register and then interspersed, with lay pins proper, and removed for re use, and they are only about 6 point thick by about 1/2 an inch wide and could actually be used in long lengths, with of course the obligatory dress making pins to hold the stock down if, the run was in dozens rather than thousands. An old friend took this one step further and actually made tiny corner brackets, to lay to left and right in addition to his permanent lay pins. O.K. if its a little platen Adana style (aluminium) or you are using too thick packing, its back to the drawing board. Obviously a good unit doesnt get vandalised, but presumably as here fridges/freezers are going for decontamination, by the second, plus with a few feet of said magnetic strip spare, within hours/days every available upright steel surface, will have paper items stuck up on hand/on sight, Not as per Bob Dylan “Blowin in the Wind” Try it!! how many or how few, sheets will you expend, pushing the temporary magnets, up down left right, leaving the original sheet in place? and double hitting, as you say.

Friends,

I received an email from “typenut” expressing concern that by this “Quick and Easy” posting I was “shallowing the waters….. (see below).

I’ve included my response to him.

Sir,

I am just a Letterpress printer with a swiss Masterdegree as such.

By promoting such Photos and calling it makeready you may just shallowing

the waters for the sailors exploring the oceans of letterpress.

Dear typenut.

As I said in the introduction to my posting. Purists please don’t read this.

I have been printing letterpress as a hobby for over 30 years. It is a hobby. For some it is a business. For some it is a art form. For some of us it just a way to express a creative outlet.

In the 30+ years that I have been printing I have never taken a dime for my work but have taught as many as 50 different friends to participate and enjoy letterpress.

Several of these people have taken up letterpress because they got hooked. For others they have understood the beauty of letterpress and have a greater appreciation for what it takes to create a printed piece.

I frequently see posts on Briarpress that make me cringe, in that I feel sorry for some printers, for the efforts, methods and materials they use to “explore the oceans”.

Some use gasoline and kerosene to clean their presses, some struggle with inadequate tools, presses, ink, type, forms and all manner of things.

An amazing and creative dear friend of mine and renown artist and art director, Bob Jones, (long since passed away), who operated the Glad Hand Press as a hobby press in Stamford, CT, taught me these words regarding printing- improvise…improvise…improvise. Together we broke all kinds of “purist” rules in creating some really fun and interesting projects.

If we were to do as you suggest and not take advantage of simple techniques that allow novices, journeymen and masters to “explore the oceans” with more ease- then I would say that you would probably be upset with the fact that Gutenburg allowed for the democratization of knowledge by creating moveable type.

So if Gutenburg shallowed the waters to knowledge, more power to him!

Sorry to have upset you,

regards,

s

As a Girl with a kluge, I seriously looked at this person’s makeready …several times…would I try it….yep…would I try a typenut…MR …well he doesn’t offer one…..what does he offer but the same BS as STAN P….same no help

I see typenut’s point, in that Steve calls his group of pictures ‘Quick and easy makeready’ when it is only the first step in what can sometimes be a long and annoying process. Reading further into Steve’s description he does state that this is how he starts his makeready, so I don’t believe that it was his intent to claim that this is all you have to do to get a job ready to run.

There are as many ways to make a job ready to print as there are printers, and there is no reason to belittle folks who wish to experiment and find ways to speed up any part of the process. There are a lot of silly things posted on this site, and there are a lot of beginning printers who need direction (as my father says, “No need to re-invent the wheel”), but there is always room for experimenting. Heck, without experimentation we might have never had printing.

Paul

Get your knuckles dirty with ink!!!!!!!!!!!!!!!!

Steve you show those old boys how to print!!

It was fun while it lasted -good by

Steve

Just a minor note here. There were no such concepts of “invention” or “experimentation” in the 15th century. These would convey something that was at odds with the prevailing understanding of the individual and his role in society. At most, “perfection” was claimed. As translated, perfection would “simply” mean improved upon. Hopefully the difference is understandable. It’s probably never a good idea to hold hands with the dead. They might not appreciate the reference.

Gerald

Add on:

By the assistance of the Most High, at whose bidding the tongues of children become eloquent, and who often reveals to the lowly what He conceals from the wise, this noble book, Catholicon, in the year of our Lord’s incarnation, 1460, in the mother city of Mainz (which belongs to the illustrious German nation, and which God has deigned to prefer and to raise with such an exalted light of the mind and of free grace above the other nations of the earth), was perfected, not by means of quill, reed, or stylus, but by the admirable concord, proportion, and measure of patronae and formae …

[Colophon from the Catholicon of Johann Balbus of Genoa. This passage is thought, by some scholars, as possibly the sole surviving statement of Johann Gutenberg on the printing arts. The Latin terms above are often interpreted to mean the devices used in the production of mechanical writing, i.e., printing equipment, or more specifically, the apparatus of transformation: punches>matrices>type.]

I cannot resist saying this. The initial part of that first sentence in my Add on is thought to be in tribute to Joan of Arc. Her influence throughout Europe was phenomenal at the time.

Gerald

Equally amazing to me is the author’s (Gutenberg or no) of the understanding of the primary implements used previously in writing’s evolution (quill, reed, or stylus). It’s not like there was a good understanding of historical precedents then nor readily available resources. Even Joseph Moxon, the first to document the history and practice of printing, some two hundred plus years later, was fairly clueless.

Gerald

To Girl with a Kluge:

I’ve not gotten involved in this discussion (nor not too many others lately). I don’t know what your problem is, but, as I’ve asked you before, please leave me out of it.

And you talk about poo-pooing people, yes, I’ve tore-up Mike Phillips for the criminal acts of his with taking subscriptions which he never intended to fufill. I you want to defend him, fine, go ahead, as this is a discussion forum. But allow me the same privilege. As I’ve asked you before, leave me alone and go pick on your friends.

Your post of December 1st:

“As a Girl with a kluge, I seriously looked at this person’s makeready …several times…would I try it….yep…would I try a typenut…MR …well he doesn’t offer one…..what does he offer but the same BS as STAN P….same no help”

Talk about “BS” read some of your own stuff, you certainly will recognize it.

I realize dad’s wisdom in his advice: “Never have a battle of wits with an unarmed person.”

I again state, I had no comment on makeready, yet I get poo-poed.

Boys and Girls,

Please behave yourselves.

Let us disagree on practices of the craft in a polite manner here on the forum.

If you wish to personally criticize another, please do so privately. Please consider the many others who read this forum regularly and do not find criticism of individuals to be pleasant reading.

I do believe in freedom of speech, in the proper place.

ok dad. we’ll behave.

I’m not giving away any of my secrets.

It may involve chewing gum or something.

Hey Inky:

Sorry.

I tried. I sent a personal email asking, in a nice gentlemanly manner, to be left out of her attacks on me.

That didn’t work…

I guess we’ll get the negotiatiors for the Palestinians and Israelis annual peace treaty, and try to settle our differences.

Hey girl, let’s cut a deal, you leave me alone and I’ll leave you alone!

This will give you the opportunity to pick on somebody else for a while!

Thank you.

Stan Pekala

Girl with a Kluge

Rummonds: Printing on the Iron Handpress

pp: 57, 213, 335. 330-331, 333

Buy the book and read.

Typenut taught me how to print and work on my handpress over 2 years in private study at his shop.

I resent to see my Teacher slandered.

Maybe if a certain someone with all these claimed masters and Phd degrees in this that and the other (there’s a masters degree in letterpress?) would just not find the ego need to mention that with each and every response, and actually not be so didactic in the responses, as well as using the correct English sentence structure, grammar, and spelling of someone so well educated, everything would be cool.

Just saying.

“Makeready” has more than one meaning in printing.

In letterpress, it can refer to the layered packing to adjust pressures for a specific job.

But in commercial printing in general (letterpress, offset, whatever), it refers to all the processes of making a job ready on press. That would include getting position, as well as such things as setting up the feeder and delivery and ink fountain, and can even refer to waste sheets. This terminology comes from trade usage: makeready is all the preparation done on press for a specific job before a sellable sheet is achieved.

There was a “Makeready” show in the early years of the SF Center for the Book. A graphic designer with a recent infatuation with book arts assembled waste makeready sheets that had layers of overprinting from many different jobs, mostly offset. One local strictly non-motorized printer was indignant, because in his narrow definition he expected to see packing, spot-ups, stab-sheets for letterpress, nothing lithographed.

Sure, Eike, Rummonds is a good source as far as he goes, which is not past the era of the iron handpress. Printing practice and terminology have evolved a lot since then. It helps to know your roots, but the trunk, branches and leaves have equal importance, and when you start separating them, the tree dies.

The printer I just mentioned, who only knew one definition of makeready and objected strongly to any other, studied with Rummonds.

The basic principle of Makeready as outlined in Rummonds book applies to every press, it is not exclusivly to using a handpress. The parts of the book which deal with typesetting and such are as general as possible.

I also learned to use other presses, including a windmill.

And yes, Mijn Engels is niet perfect, want het is niet mijn eerste taal.

If only people with proper grammar and etc. can post here, it would be kinda a lonely place - no?

PS: in offset printing -

Prepress: Film, stripping, plate, color proof etc. I worked in that Field. Offset doesn’t need Make ready per se, it’s more adjusting color, water or solution flow etc. But is was common to call the sheets used in setting up the press makeready.

In Letterpress it refers to even out the pressure on the form to achieve perfect inking by using layers of thin papers to achieve that.

Ian Mortimer of IM Imprimit produced a book on printing the Pouche Wood type, it has nice illustrations explaining it all.

Briar could always add extra threads, one for disagreement, one for being contentious, one for say anything you want openforum speak easy kind of thing, potential slander libel, virtual wrangling ring……..?

Or a traffic light system approve/disapprove , vote up vote down like comment blogs in newspapers….

!

Eike, from your list, sounds like you’ve worked more in litho prepress than in a commercial pressroom. Rummonds as a source says nothing about commercial motorized typesetting or presswork. Or photolithography for that matter.

Pressmen, whether working in letterpress or litho, with autofeed presses, still have various processes of “makeready”. At least that is common terminology in the US; maybe this is another tedious intercontinental difference in terminology. But to a US lithographer, those run-up sheets in the delivery are just as much “makeready” as any letterpress stab-sheet.

To be precise and use the proper term as it has been used in the printing industry, that sheet you’ve placed in the packing to adjust local pressures is an “overlay”. To insist it is “makeready” and only that can be called “makeready” ignores the last century of printing usage.

Parallel-Imp

Overlay - underlay

Part of Makeready as a process -we agree on that?

I haven’t insisted on anything. At most a general Statement.

But that seems to be the norm anyway.

This get’s tiresome.

Way down south where the bananas grow. a grasshopper stepped on an elephant’s toe…the elephant said with tears on his eyes,”pick on somebody your own size,” I am a girl, I don’t have friends…I did not realize Briar Press was a popularity site. You win

Look Stan, I am sure you have years of letterpress experience, and all

of us could benefit from your knowledge if you would share it instead

of poo-pooing people. You asked me one time, why I have a kelsey when

I have a kluge, for the same reason you don’t have only one press.

I love my kelsey. I have hauled that press all over teaching boy and

girl scouts about printing and helped them earn their badges. If

someone wants to print 200 invitations and envelopes why not on a

table top press? Yes, they have limitations, all presses do. But for a

small run, even if they have to cut the die and run it in two passes

it is still cheaper than what todays letterpress printed invitations

cost see Elum for example: http://www.elumdesigns.com/

Find a design/card enter a quantity and I think you will be quite

surprised. The dealer discount is 40-50% depending on the item. Can

you produce it for that price?

Here is a picture of a recent card I printed on my kelsey. I didn’t

print this on my kluge or windmill because it is #220 lettra and both

presses want to grab double or even triples…on the windmill if I

have the impression jacked up and the packing with an offset blanket

or dental dam under the tympan and then take extra sheets….I’m

probably going to be replacing the shear collar on the windmill, on

the kluge I would have to put long bolts in the flywheel and put a

long bar between them to release the press when it stops dead cold and

locks up on impression. I don’t have that problem when I hand feed the

lettra…more control. Lettra is 100% cotton and wants to cling to the

sheet next to it, even when hand feeding. There is a press for every

job and a job for every press.

I love my big presses too, but commercial printing is a completely

different ballgame than hobby printing. I do both and have for several

years. I freely share my knowledge that I have aquired over the years

of working at a company where the motto was “Find a way or Make One”,

and believe me we did. We got all the shit jobs that no one else

wanted to do or could. I still work there part-time/on-call because

there aren’t many people with the skills left to operate the

equipment. Printing times are hard now and many companies are

operating very lean (thanks too six sigma and the collapse of the

economy). I personally am tickled pink that young people are coming

out of higher education and want to learn how to print via

letterpress….they can have my job and maybe I can retire (someday).

sorry, but you do have friends, at least one anyway. i have seen things you printed on the big presses and also on your kelseys, i’ve never run large presses like you and probably would not know where to start, i’ve learned a lot from your posts and am grateful for your sharing of your knowledge, i believe it is good to keep this old stuff alive and pass the information along to the younger kids. Dick G.

I learned letterpress on the run in a poster shop where the type was worn out, and every conceivable make-ready trick was used to try to make something presentable for the customer. The jobs were almost always short runs of 100, and often we would still be applying an underlay on the 98th sheet. If you know your press and work it regularly then make-ready can be very simple, but there are times, when on the clock with a client waiting, that every printer breaks the ‘rules’ and finds the quickest and easiest way to jam the job through. Finding that balance is the only way you can produce anything and make money.

I’ve made ready under the tympan, on top of the tympan, under the form, and even taken individual letters out and applied enough kraft tape to bring it up to height. To argue that there is only one way to make-ready is ridiculous. No two jobs are ever the same, and even with the same form it can change after 10 sheets and you have to adjust it, or the same form on a different day will run completely differently. To make-ready a solid page of type is completely different from a poster, and a polymer plate will run differently from metal or wood type.

If you have a process that works for you that’s great. If you learned from an anal-retentive hand-press printer that’s great. If you learned on the job from a 70 year old gentleman who had been in the business for 50 years (like I did) that is also great. If you learned in a 12 week college class that met twice a week for 2 or 3 hours - well, there’s hope for you too.

Paul

Devils tail …

re sticking bits to the back of the individual letters on jobs ,in itself its not really wrong to do that ,if the type is varying in height in the form and a line then to build the letters up to one height is require d to get good inking and that can only be done letter by letter so although sticking crap to the back of the form may be frowned on it is as you know necessary. That too must also be makeready by description

As for how we got here well that doesnt matter its what we laid along the way to pave the way for those who follow , letterpress is an old method most of the kinks have been ironed out of it and the faults that are left are dealt with in many different ways but a means to an end is justified if the job gets a pass and goes through the mail on time .

To reiterate the basics:

-an underlay goes between the bed and the form

-an interlay goes between the base and the plate

-an overlay goes in the packing

Makeready may include all of these, and a lot more. Tedious, but factual, actual trade practice.

I don’t know why I got dragged into this discussion- noone invited me either- but I somehow feel compelled to comment.

Steve’s original comment is not that different from what many would use for screenprinting makeready whene micro-register isn’t available.

A lot of us hand-screenprinters, when not using an auto press of some kind, will just print to a clear mylar sheet with tape on one edge, pop the vacuum off, register a sheet of printing paper underneath it, place some tabs, take the sheet out of/put back into position, and then pop the vacuum back on and check alignment with a proof. From there it’s a matter of making sure each sheet goes into the guides at the same point. Really no different.

And in screenprinting circles, some people refer to this as alignment, not makeready- and then there’s peel adjustment/offcontact adjustment, in formulation, and even vacuum pressure for sheet hold-down- but really every aspect of the process tweaking before actual feeding is- in effect- part of makeready.

You’re making the press ready to print.

Then, you feed the press and print.

Offset, Digital, Screenprint, Letterpress, Flexo- it’s all the same thing, just different knobs to twist and gauges to place and stacks to load or pile up. We’re all Brothers and sisters. let’s get back to printing.

Steve, I wanna add here that this has been by far the easiest way to make a setup since I started printing over a year a go. I just gave it a go today, and this with the addition of the suggestions on the gauge pins thread I was able to make a very quick perfect setup and a damn tight registration.

I’m very happy! Thank you for sharing this!

I just noticed something wrong with Steves pictures, i thought he is left-handed???

Dick,

Nice call! I am a lefty and so is my wife. By bringing friends into our shop/home a teaching them to print we discovered that I had been using the feed board for delivery and the delivery board for feeding. I’d also set the side guide on the right which made it easier for us and more difficult for most of our guest printers. Hence the name Southpaw Printers.

Oh, and the hands in the photo…Raliegh D”Adamo, a righty of The Cedar Cliff Press.

Have a good night,

s

Thanks for the very good info on alignment and such. As I enter my second year, I use deli wrap paper (thin and lightly waxed and cheap or those mylar page protectors which are easily wiped down) over the tympan, print an image and then set the pins. I am still working hard on the “which direction to move the pins to accommodate uneven setting” but getting there. Personal stuff aside, this forum is a gigantic help for those of us without a teacher who are self-taught and know how far they have to go. Thanks to all.

Dear typenut, Eike and Stan P. I am sorry for my comment. I have not been through the rigorous training and examination schedules that you have. As I curtsy to you, please accept my apology.