Baltimore Jobber No. 4 — Building vs. Finding New Rollers

Hi everyone. I’m new to Briar Press and letterpress in general.

I’ve inherited a J.F.W. Dorman Baltimore Jobber No. 4. It’s been sitting for a while. I’ve been printing and slowly working out the kinks (it was missing a foot pedal, so I built one).

My next issue is that I’m not getting even ink coverage. I stood above the press and watched the rollers as they moved back and forth away from the bed. At first I thought that the rails that the trucks rode on weren’t straight, but I double checked and they are perfectly straight (I’ve also taped them with strapping tape so that they are exactly type high). I double checked my trucks and they are perfectly round (or as close as one can get). I rolled my rollers on a flat surface and then I saw the problem.

One roller is bent. I can see light coming through the center, and then when I roll it 180 degrees, light comes out the sides with a corresponding curve. I tried unsuccessfully to bend it back with a come along and some rope, but that’s another story. With the other roller, I suspect the core is off center in the rubber. When I roll it on a flat surface, no light shines through at any point, but it rolls like an egg, heavier on one side. I took the rollers to a professional, experienced printer who is a friend of mine and he confirmed that this is the case, not some other factor in my setup. We have no idea what caused this.

Rather than try to refinish those rollers that have potentially bad cores, I’d rather just buy brand new ones. Is it possible to get rollers for this press? I have not found anything online. I’m guessing that no one sells this since C&P, Heidelberg, and Miehle Vertical seem to be the only rollers I can find. Are there any rubber refinishing shops that can help me?

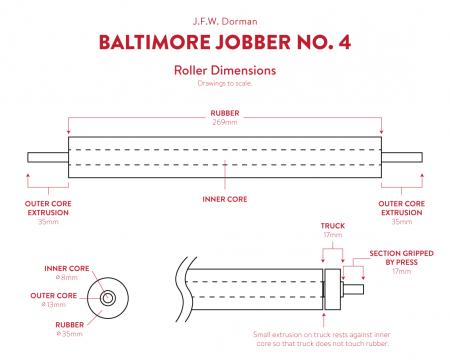

If I can’t buy them, I was thinking I could build them. I could get a local machine shop to turn some new steel cores for me on a lathe very cheap, and then send those off to get finished with rubber. I’ve drawn up the dimensions of my existing rollers and attached it. Here’s a dropbox link for the full-res.

https://www.dropbox.com/s/09yga95x4qt1aeh/Baltimore-Rollers.png

Can a roller refinishing shop make rubber of any diameter or are they locked into specific diameters? What are the differences between a roller with a large diameter vs. one with a smaller diameter? As I understand it, the roller diameter should be equal (or ever so slightly larger) than the diameter of the trucks, so that it just barely kisses the type. I’m asking this because I’ll probably have the machine shop turn me some brand new trucks too, which need to roughly match the diameter of the new roller.

Sorry for the long post! Any advice or suggestions? Thank you so much!

baltimore-jobber-4.jpg

Baltimore-Rollers.png

W U T Sir, many many misconception about rollers for Vintage Presses, contrary to what Mr Motormouth tried to say some time ago, taking me to pieces, ON LINE stating that trucks and rollers HAVE to be the same size?? Look up ADANA (on line) rollers and observe!!! rollers and trucks/wheels with the compound of much less circumference than the trucks, SEE also same Adana Rollers priced In $ Dollars ?? BUT NOTE ALSO they, (the rollers) are pictured AND specified with 2 stage REVERSABLE trucks to eliminate all this *to Tape or Not to tape* trucks and bearers??? . Logically Standard normal/original height, and reversed at bigger diameter to take worn trucks/bearers into account, !! not exactly rocket science, Mr. M. as above must have had an optical or mental block, when it came to the Paragraph where I stated that I had, on sight/in front of me at time of posting, 3 (three) sets of rollers, A, S/Hand Thompson, (British Platen) with the compound at least 3/8” of an inch, less circumference than the trucks?? B, Adana H. S. 3 Rollers, with the Compound at least 1/8” of an inch less, than the Reversible Trucks, and C, Adana T.P. 48, Treadle and Power Platen, also with rollers, and the compound at 1/8” Less than the Trucks?? . . I didnt even bother to stoop to Mr. M,s level and mention your own, Morgan/Delrin expanding Trucks, (in essence altering the size/diameter, of the trucks in relation to the roller compound.)

Dont take my word for that, YOUR OWN, TARHEEL ROLLER & BRAYER Company out of Clemmons, N. C. will corroborate???

With your drawings and spec,s you imply Metric dimensions for the cores/shafting etc, a micrometer will surely tell you Imperial Measure, i.e roller extensions at 3/8” or 1/2” etc, by implication!! No high Tech machining down, for new cores, Just standard, Steel Stock, Probably either E N 16/24 or E N 1 A, Off the shelf.

N.B. Whereas, in the past the shafts would have been Knurled, to accept cord windings to aid the adhesion of the compound, our U.K. Graphic Suppliers, (must be same Stateside) are quite specific, that is no longer a requirement!!! . THE COMPOUND is now Chemically bonded to the shafts, and generally/usually, with rubber they are Re-Cast and ground down to whatever size is requied/specified, the foregoing may help with answers to some of you questions, your U.S. Graphic Suppliers must surely be on a par with U.K. if not superior.??

Your drawings lack a critical dimension - the roller and truck diameter. My rule of thumb is that the maximum diameter you can put on the press is a bit less than the minimum center-to-center distance between roller hooks on the same side of the press. I suggest that you check your truck diameter carefully if you want to re-use the trucks, and order rollers that diameter. It’s helpful if the roller diameter is an even fraction of inches — 1-1/4 or 1-1/2, not 1-19/64 — as the roller company can more easily match that. However, for rubber rollers which are ground to a finished size they can probably match whatever size you want.

If your roller diameter differs much from the truck diameter you will get slurring of ink, or the rollers will bounce around on the type with the trucks off the rails. If your rails are type high or a couple of thousandths below, and/or your rollers are the same diameter as your trucks or a couple of thousandths more, you will get satisfactory inking. However, that will not be quite the same if you get composition rollers, as they change diameter with the seasons or the shop humidity.

Bob

Thanks so much for your help Bob. I did actually include the diameter of the roller, 35mm (it’s on the lower left). I didn’t include the truck diameter because it was so much smaller and mashing the roller into the type, I assumed it was wrong and taped them.

Your explanation of the maximum roller diameter was perfect, totally logical.