Poco 0 proof press problems…

Hi, all…

I am hoping there are folks out there that can help me with my Poco 0 proof press. I am having some trouble with adjusting the press so it works smoothly. I’ve looked through the archived discussions and can’t find much info on my problems. I’ve been looking at the https://sites.google.com/site/pocoproofpress/home website and it has been enormous help, but my issues aren’t addressed there.

First off, I am not sure how smoothly the press should roll when turning the handle, but my guess is that it should roll more smoothly than it does. We had to take the press apart to move it, and my husband seems to think it used to roll more smoothly before the move. It seems to roll ok, but takes a fair bit of pressure on the handle to work it. It also doesn’t seem to roll consistently…more pressure is needed at the ends than at the middle. It kind of clunks when it hits the middle.

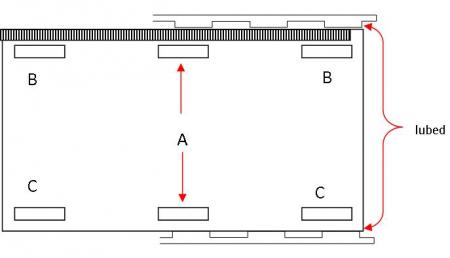

I read somewhere in these posts that the press bed should ‘high center’ on the middle sets of rollers (A on diagram), and should rock a little when the bed is centered on the press. Is this true?

We have checked the press for ‘square’ and for level, and it is both. On the press, the right under side rollers (B) on either end of the press do not engage the bed at all. The left rollers (C) do…both sets of rollers needed much persuasion to move at all, so my guess is they have been in the original position for quite some time.

We applied gun oil to the oiling holes that were specified, but it seems to make no difference. We also applied petroleum jelly to the sides of the press bed where it meets the small flanges on the frame of the bed (just under the gears on one side and the same location on the other) to no avail. We have not applied lubrication of any kind to the large gear on the cylinder or the large gear on the bed.

When the cylinder is centered on the press, should the gap where the tympan and packing is tightened up be at 12:00?

Thanks in advance for any information you can give me…I really appreciate it.

poco1.jpg

What you are describing does not sound right at all. I have been using a No. 2 (with a bed twice the size of yours) for 38 years and it has always worked like a dream. Very smooth running back and forth under the cylinder (in fact I print in BOTH directions). It is important to keep the rollers under the bed lubricated. I have always been told that the ball bearings in the cylinder should not need lubricating as they are sealed. I haven’t done a thing to my cylinder since 1976!!!!

The “rocking” and “clunk” in the middle would be a real concern. I have never heard of this situation before. I am not very mechanically minded at all, so I love the simplicity of my Poco. My joy lies in the type and creating an attractive image.

Rick

M.J. Sir from glorious downtown Sussex U.K. just a tiny extra tip, (Possibly) I am at this time preparing a proof press to sell on, although the Top AND Bottom Ball race bearings/Bearers are/were all steel and theoretically sealed for life, and as you seem to be encountering!! still too stiff, I could have changed 4 Or 8 bearings/bearers, but as they were still sound, if maybe a little short on the pre-packed grease, although in theory, *PACKED FOR LIFE* I hedged my bets, removed all 8 bearings/bearers, placed them in the obligatory *Bean Can*?? with enough, petroleum Jelly, to cover all 8, and higher, warmed it up with gentle blow torch, NOT boiling, just enough to give gentle bubbles on the surface, and then stood to cool for some further 45 minutes,ish, in a bowl of hot water, allowing the Vaseline to leech back into the bearings, to capacity!!! refitted, adjusted the eccentrics, and now by comparison, to previous, it FLIES, . . so much so that on the first test pull/proof it (the carriage) hit the bump stops, but fortunately, tested the newly fitted Leather Buffers.!!!

The carriage body is entirely 3/4” solid brass, and was slightly clinging to the bed rails, (with many years of ink dribbles and solvents) cleaned up!!. . Only a simple proof press, but no apparent means for side play, but that was not the main problem, re lubing the bearings and adjusting the eccentrics, had the most effect.

My best shot, should it help. Good Luck

As others have already noted, this does not sound good. Poco’s should move very easily the entire print cycle with no noise/clunking or tilting of the bed. Depending on when your Poco was manufactured the rollers may be adjustable. That is you can raise or lower them because they are on an eccentric shaft. It is often missed if you don’t study the parts carefully. If your press has rollers connected to each side of the press without an axle between them they are the ones that are adjustable. If you have an axle that connects rollers from one side to the other, you do not have adjustable rollers. And yes, they could be out of adjustment and causing your problem. Also, you ask if when the cylinder is centered should the opening be at 12:00. I think you mean if the bed is centered should the cylinder opening be at 12:00 and the answer is yes*. You want the solid surface of the cylinder to hit the most bed it can without the opening coming in play. *You may have a personal preference to alter that by a few teeth if you use a chase and determine by trial that the opening is not falling in an ideal position for your set up.

John

PS Here is a pic of a Poco I restored and it shows the solid axle type that is not adjustable.

poco.jpg

I just found another post about what I tried to explain. It has a photo of the eccentric. http://www.briarpress.org/37142

John

Sorry you’re having problems (but nice diagram!).

I tried to adjust mine so that whenever the bed is above a roller, the roller is moving. So as the bed moves from side to side, it just glides back and forth, with no rocking in the center.

Your description of the rollers being difficult to turn sounds wrong. All those parts should rotate smoothly and easily. While you may not want to tackle the job, and I wouldn’t blame you, I would take it apart, clean things up, lubricate, and reassemble.

If you’re nervous, find a machinist to help. He won’t have to actually machine anything, just help assemble, disassemble, etc. He can also help you find appropriate lubricants (petroleum jelly is a bad choice).

Good luck,

Preston

Thank you all for your help…and a special thanks to Preston, who took the time (and the ferry) to come to my house and help…under his knowledgeable and skilled hands, the Poco is now running quite smoothly and we even printed some odds and ends that were on a composing stick to prove (proof) that it is working fine!

IMG_20140323_232431.jpg

btw…turns out one of the problems was a frozen pin at the end of the bed which was riding on the smooth track next to the gear strip and clunking down when it came off the end. Pin finally gave way to a ‘bigger hammer”;-), and was rotated so the flat side was down, and it no longer rode on the track. Along with many other adjustments, Preston was able to get the clunk out, and the press working smoothly. Kudos to him and his lovely wife, Marya, who set up the print we finally were able to make. They are truly jewels in the letterpress crown.