Heidelberg Windmill Cam operating clack valve problem

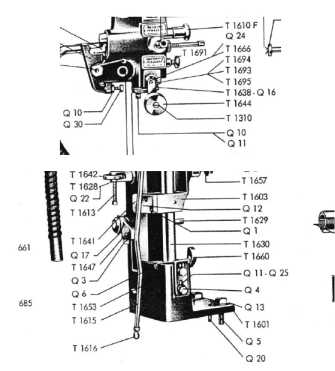

I bought recently a Heidelberg Windmill, and I have a doubt about one mechanism. I attached a picture of this mechanism. The “Roller operating clack valve” (T1644) didn´t touch the “Cam operating clack valve” (T1660). There is another adjust to do (Already tried to adjust cam operating clack valve up and down, but didn´t work)?

What about the mechanism from image3? What is this for?

Image1.jpg

Image2.jpg

Image3.jpg

It would be very helpful if you could post a link to a video, so we can see the action of the assembly.

In the meantime, the two parts should touch when the assembly rises up, to open the valve and release the suction after the sheet is grabbed by the gripper.

The third picture shows the flexible joint in the sucker-bar lever. The lever raises/lowers the sucker-bar.

Do you have a manual for your press? You can see an online manual here:

http://users.bestweb.net/~bpress/manuals/heidelberg_1015_manual.pdf

Look on page 70

Parts-book is found here:

http://letterpresscommons.com/files/2012/10/heidelberg-10x15-parts.pdf

Hello,

There is nothing in the user manual telling how adjust the “Roller operating clack valve” (parts list number T1644) and the “Cam operating clack valve” (parts list number T1660).

The image and video are here:

https://onedrive.live.com/redir?resid=40B9096B0167E173!634&authkey=!AB7-scf5b7b1wAg&ithint=folder%2c

Thanks for the help…

Excellent pics and video.

It appears the cam has worn down dramatically, likely from earlier failure to lubricate the clack valve lever and roller.

If the lever is now free to open the valve, I would add metal to the cam to bring it back to the original height. I am away from the shop for a while, but later will try to get that dimension for you. (Other members, feel free to provide that info, in the meantime, if convenient.)

I measure the cam high point at .768”, it is fairly semi-circular shaped.

Hello AnonyMouse, thanks for the help.

Looking very close to the cam , I can´t see and imagine a worn so large. To solve for now, I will add a metal in the cam to get the original height.

Just for information, I was looking to a picture from another machine (older than mine -link: https://onedrive.live.com/redir?resid=40B9096B0167E173!635&authkey=!AJZf1-UsVfqa_7Y&v=3&ithint=photo%2c.JPG ) and I saw the cam very high. I guess the cam is different from old and new machines (not sure about that). My machine serial number is 176083 (1970). A friend of mine has one machine too, with the same age of mine. I will check this with him and then I tell you.

Yes, wear would seem extreme. But I have only seen semi-circular shaped cams on newer and older machines.

Perhaps someone modified the cam to keep the valve closed, which is not needed on a machine with the “thin stock knob” T1691. That knob may be stuck from infrequent use.

Hello AnonyMouse, good news….

I saw my friend´s machine, and the cam is like mine.

Trying to disassembly my machine, accidentally, I removed the screws in red rectangle number 1 (image) and tryed to remove the screw in red rectangle number 2 (image). This screw is off center, so we can adjust all the pickup system. Now everything is working fine.

Imagens and video link: https://onedrive.live.com/redir?resid=40B9096B0167E173!666&authkey=!AD2jTrq4VOJEXnE&ithint=folder%2c

Thanks for the help again…