Another Hacker No.4

This is another Hacker No. 4 that is now found. I wanted to share a little information on these presses as many may know much about them because there are so few. I also wanted to reach out to the other Hacker owners. But first, thanks to these folks:

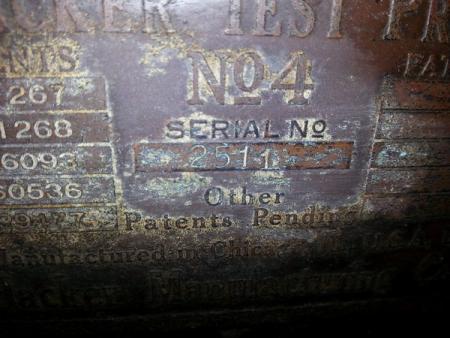

Fritz Klinke at NA Graphics (http://www.nagraph.com/) who looked up the historical information on this particular press in his archives. It was sold 1/31/1929 to Grey Ketterer & Hansen, Inc. and worked on by Stanley Metza, an employee of Vandercook on 3/26/1957 while it was at Columbus Engraving Corp.

Paul Moxon at http://vandercookpress.info for hosting the census and providing the 1936 catalog. This was most helpful in preparing for the move.

Scott Moore at http://moorewoodtype.com/ who built the base for transport and help load it up. (It was really the other way around, I helped him and handed him tools.)

Finally to Nancy who took the time to make sure this press made never made it to the scrap yard.

I will be restoring this press back to its original beauty. I am looking forward to using this press to print on as well using it for troubleshooting plate issues on other presses.

Hacker Test Press information:

It was more than a proof press; it was a TEST press. The intention of the press was to reduce make-ready time. It could test plates, ink, ink and paper combinations, register of color plates, color of color plates, etc. There was an advertisement in the New Inland Printer Vol 5 from the Reilly Electrotype Company, Inc. that boosted the Hacker as their testing press for all outgoing plates.

The polished ground cylinder carried only .012 to .015 packing allowing for a more precise test of plates.

Printing distance, bed to cylinder is guaranteed true within a half-thousandth under load across the entire bed, allowing as many plates as you could fit on it to test at one time.

Feed guides both front and back have micrometer graduations and adjustments to .001”.

The bed and cylinder are held together during the printing stroke by powerful springs applying equal and measured loads to each side. Printing load is 200 pounds per impressional inch, with an overload made possible by the springs. The springs will allow a temporary overload without damage to the press.

Used in Photo-engraving plants.

Bed Size: 18 ¼” X 25”

Weight 1800 lbs.

More info on the Horace Hacker & Co. can be found at http://vandercookpress.info

rsz_20141014_210302.jpg

rsz_120141011_204627.jpg

rsz_120141014_210316.jpg

Looking at your photographs, I get the impression that the builders of the Eickhoff proofpress in Denmark, must have seen a Hacker at some stage. The base, the bed and the feeding board etc. all look very similar.

Here is a photo of a #4 Hacker that was taken for the brochure that Larry mentioned. This was scanned from an 8x10 photograph made from the original 8x10 film negative that we have in the files. I think I also have all the blueprints for this press. Hacker was far more advanced in the era of these presses (late 1920s to mid -30s) than his competitor, Vandercook.

https://www.flickr.com/photos/53177163@N00/8712416433/lightbox/

fritz

Thanks for sharing this photo. Interesting that mine looks the same in the middle, but has a different base and feed boards. I guess the #4 went through a few changes in the years it was made. Glad you have the blueprints, I know there are no spare parts anywhere.

There are definitely variations of the Hacker no. 4.

Mine was older and low-end, had about half the inking system shown above (also a handle that pushed against a coil spring around the cylinder shaft rather than being fixed directly to the shaft).

It had non-adjustable head stops and grippers that closed onto the packing rather than gripper pads.

That press would be configured more for a composing room than a photoengraver.