Trouble with inking (?) on Vandercook 317

Hi -

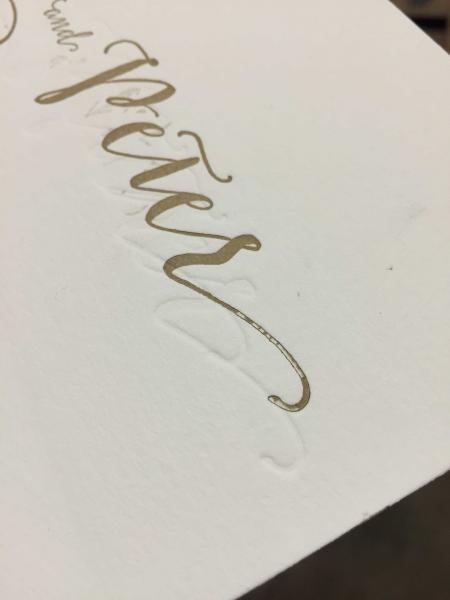

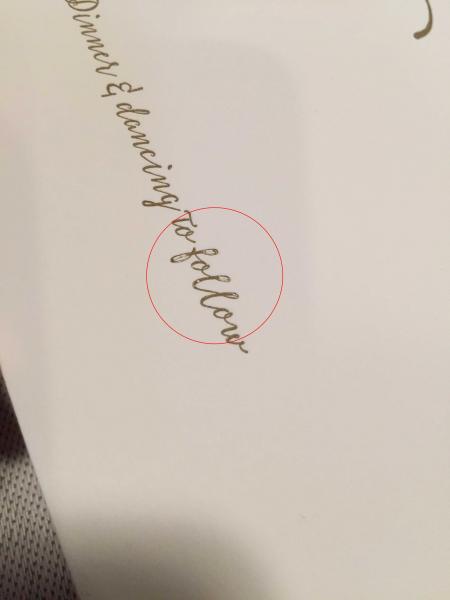

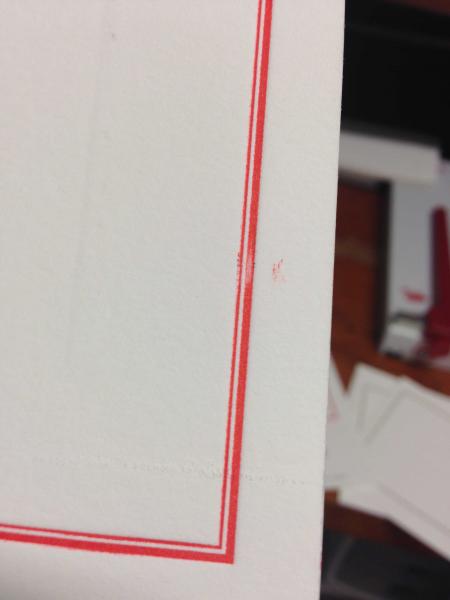

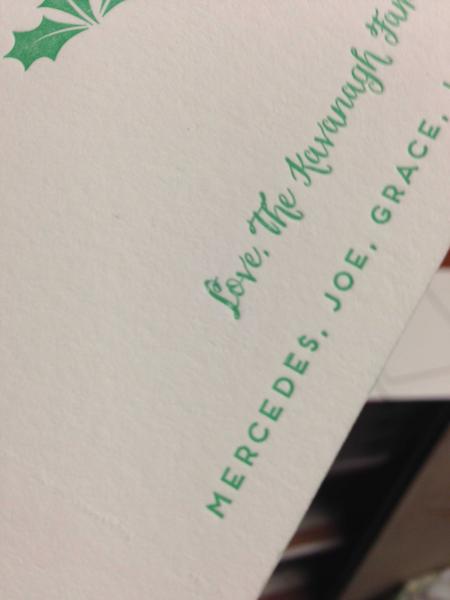

I am running into an interesting quirk on my Vandercook 317. It has happened on a couple of jobs so far, but not every job. Basically, on certain areas of the print, the ink is not appearing even though the paper is getting an impression. Images attached of the few times I’ve run into it. To troubleshoot, I’ve tried a few different things including:

- Adjusting the packing

- Adjusting roller height

- Readjusting the plate

- Repositioning the paper

It sometimes is resolved if I change the direction of the plate on the press (for example - on the image where the trailing “r” was being funky, switching the direction of the plate from horizontal to vertical resolved that issue. It unfortunately just caused the same issue on different text further down though). The ink does appear to be transferring onto the plate, but for some reason it’s not printing crisply onto the paper.

I’m not quite sure what else to do to troubleshoot it (or even what could be causing the issue). Any suggestions on what else I could try or what might be the root cause?

Thanks so much!

image2.jpg

image5.jpg

image3.jpg

image4.jpg

What are you using to clean your plates and rollers? Any chance there’s some solvent residue? Who makes your plates? Have you inspected them closely?

If you determine it is not the plate, and not a solvent/contaminant problem….

It may be a presswork problem.

Are you taking care not to allow the paper to slap around the cylinder too much? If you’re printing with a rigid stock, or not minding the grain direction, or both… You can run into issues where the ‘tail’ of the stock touches down in places. Bowed or uneven paper would touch in roughly the ‘high’ spot of the paper, so if there is a cockle in the sheets, it’s highspot is likely to be in a similar place in the pile of sheets you’re printing from and to cause a roughly similar problem with your presswork.

You may need to print ‘work and turn’ to solve the issue. Example- You want to print one 5x7 card. You think you can fit this on a 6x8, trim a 1/2” off all sides, and that will work.

In fact, you should be printing on 12x8 sheet. Print all your sheets, rotate pile of finished sheets 180 degrees, print again.

This will leave you with a ‘tail’ to follow around the cylinder, allowing the leading edge to conform to the cylinder instead of prematurely touching the plate.

It could solve your issue and is worth working with the next time it comes up.

A lot of people try to cut corners with printing stock…. And in my opinion, it is inexperienced foolishness when it drastically can solve your potential problems to work WITH the process, not against it.

Another trick I developed here at Haven Press to work with incoming customer stocks as supplied, or envelopes, or other things that can’t be ‘doubled up’ but print really close to final size, involves some temporary liquid low tack adhesive and a mylar topsheet- but I’ll leave that for another time.

likewise I use some doublestick tape. Just enough to hold it. When it picks up too much lint, I just put a new piece on. Lasts surprisingly long.

Perhaps take a look and listen to the Film, *Medicine Man*

Sean Connery, (Dr. Robert Campbell) Lorraine Bracco, (Dr. Rae Crane.)

Maybe pay special attention to the part where Dr.Campbell has lost the means to reproduce His serum.>>>

*I found the cure for the ******* plague of the 20th. century, and now I`ve lost it.!*

Haven`t you ever lost anything, Dr. Bronx, Your Purse, Your Car keys, well its rather like that,! Now you have it, now you dont.

Could this syndrome be part of the answer to the above problems:- I. E. trying to make *A silk purse out of a sows ear* or put another way, trying to marry BRAILLE with BLOTTING with Machines that were never intended for such.??

Has anybody thought to examine if possibly the image is being picked/pulled from the print, unless freeze frame is resorted to, will it be seen.

____________

50/60 years since, (and before Braille & Blotting Paper was in the frame) EVERTHING from the Smallest table top, to the Biggest 2 rev, Meihle turned out Good print without all the Modern problems.

____________

What`s been lost along the way.???

I am not always the best at translating him but I think Mick might be suggesting that there is some ‘picking’ going on, if you’re using soft paper and stiff ink that is possible too.

http://printwiki.org/Picking

What’s the stock (make/thickness/weight)?

What’s the ink?

Are you using any modifiers?

Thanks everyone for the feedback and suggestions!

@HavenPress - I think you are right. My stock is 220# and printing fairly close to final trim size, so I suspect it is slapping down (instead of wrapping around the cylinder) and that is causing some of the issues. I think the same thing was also causing the paper to be slightly scratched earlier (although I was able to figure out a workaround for that one), but I definitely agree a ‘work and turn’ process will be much easier going forward - especially when I have thicker stock. Live and learn, I suppose. :)

In the meantime, I’ll try the double-stick tape method to see if that makes it any easier to get through this run.

Also - ink is oil-base from Ink in Tubes. Stock is Lettra 220#.

Thanks very much to all for the input; much appreciated.

Well, it seems like your issue is identified. Hopefully you can overcome it.

But Mick is right, the whole of us are using stock on these presses that often isn’t designed to go through them. Or rather, not the stock- that the press wasn’t designed to pull through.

#220 in my opinion is better left for a platen; but you have to use the tools at hand to get the job done, even if they aren’t ideal. Good luck with the workarounds.

yes, Mick is hard to cypher, even when on topic. but i have run into this on foil plates. it make take a Loupe (loop) to examine your plate, but look to see if it possibly dented, impressed, or somehow has damage to the work surface.

residue is quite possible, but it looks to me like plate is pushed in. i don’t know quite how it works, but plates seem to push in easier on the flat surface than they do right along the edge. maybe a hardening due to etching? i don’t know. i have a cut that i use the back side with 600-1500 grit wet/dry sandpaper. to “scratch” the surface of a plate. this makes an irregularity in the surface stand out.

if this happens in the same spot on the press, i would look at that. Any kind of tendencies will help lead you to solution.

Friends, Thank you One & All . . I appreciate that my ramblings although well intended are often hard to decipher, I am more than happy to be taken to task,

It prolongs the shelf life of the post(s) and frequently encourages much more good input, for the benefit of the New Ones … I am still learning. Thanks. Mick

Hello Mick, good to see you back here, thought we had lost you!

Well the other thing is, the 317 has a relatively small cylinder. You get a press with a larger cylinder the stock will more readily wrap it.

My friend Earl recently pointed out that is why the Heidelberg cylinder has such a large cylinder and only prints from a portion of it.

Thomas G. Thank you, not so much lost, just took a wrong turn.!!!

The cover story is/was a Jacket Potato got out of hand , but in Real time it involved a fairly major House fire,

My own fault (up to a point) dodgy wiring, probably will not do it again.

Haven Press, thank you also and regarding your last general post timed at 1902 (time zone unclear?) re the tiny wrap around on the cylinder of the Vandercook, which is/was, in essence Only intended as a Proof press, but of course pressed into service as a production press.

As *Earl* rightly points out the H/berg with the appropriate size Cylinder performs very well, as opposed to, for example, the Vertical Miehle which also has a very small cylinder, pro rata, and was/is well known for the *Clack* as even relatively thin stock wraps around the cylinder on feed and delivery.

M. G. D. & V.M. partly solved the problem, as implied by kmdc, above i.e. slapping down instead of wrapping around.?? by introducing a series of fingers with a virtually perfect curvature to conduct small or stiff stock AROUND the cylinder.

Is it possible that a variation of this could be adapted to the Vandercook even as an experiment.. Prove or disprove.?

Hello,

I owned a Vandercook 317 for a long time and printed a ton. The machine has no problem printing 220 pound stock. I have also used cut stock to print too.

I am not trying to ruffle any feathers here, but we print invitations (220-314lb) all day long on our Vandercooks (#4, Sp-15, 219). We never have any issues cutting the stock down ahead of time (unless there is a bleed in the design) or the paper being too thick.

We did the same on the Vandercook 317. The only reason I sold the machine was because the other presses are auto-inking.

Here is a little video I did a year or two ago: https://www.youtube.com/watch?v=5FbTW3ogL5s

The machine is a little odd on the Vandercook line as you feed the paper in on the top and it pulls through backwards.

We also have a plate maker and have made our own plates.Your plates look a lot like residue on plates, bad plates (home made), mineral spirits or oil mixed with ink.

Your issue looks to be one of the following:

1. Residue in the ink. I would clean the rollers, and ink pallet really well. Use mineral spirits on the rollers, then mineral spirits and rubbing alcohol on the ink pallet.

2. Is it always on the same spot on the press? Slowly trace the paper going through and see if you can find where it may be rubbing. There may be oil on a small roller which pulls the paper. The 317 has a lot of small rollers which allows the paper to be spit out. The machine was designed to print very fine details.

3. Are you cleaning your plates with alcohol before you print? Always use rubbing alcohol when cleaning your plates, esp if you are making them yourself.

4. Oil based ink. How long has it been sitting? Are you putting it on glass and mixing it? Are you mixing anything with it? Have you tried mag carbide to thicken it up some?

The 317 is a rock star press and there are only like 9 or so of them on record to be found. I sold mine to Signal Return in Detroit. You may want to reach out to them if you have questions/issues.

Thanks,

Pete

Old City Press