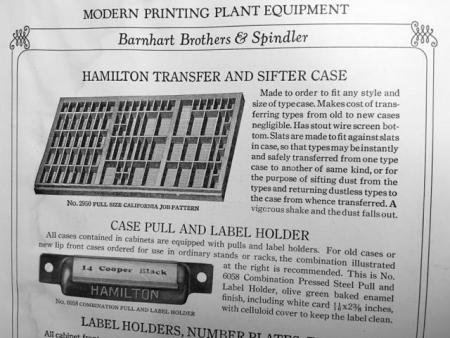

Transfer and Sifter Case

I came across a description and illustration of a Hamilton Transfer and Sifter Case in an old BB&S catalog. I have always wondered if these cases actually existed or if they were just a letterpress myth or a delusion brought on by too much time spent in the composing room.

I am thinking about making one out of an existing type case. Has anyone attempted this before? Any help would be appreciated.

IMG_2309.jpg

N.S. If you are asking, and implying, as your spiel seems to suggest, *Transfer & Sifting* plus cleaning type En Route, YES they do work.!!

As long ago as the late `50,s we were utilizing just such method:- We just took the back of of a good condition case (sacrificed it), planed the back down, bearer sides & 2 uprights in plan to view till we reached the underside of the compartment divisions, flush overall, then planed of the normal front riser that carries the handle(s).

Therefore flush front and back, then covered *The transfer case* with what has become the bottom, with fine mesh, metal Gauze, stuck or pinned on,! and then flipped/transferred for cleaning decontamination.

It took a little care and an acquired skill to*flip* over and back and Yes, we did drop 1 or 2 but as apprentices we had to learn the “Lay” much quicker.??

The metal gauze provided all the drainage for whatever decontaminate was used, including if needed Muslin or similar over the type to contain sorts when blowing off with an air line.

YES, of course there was a small migration of thin spaces etc on transfer and re-transfer, but a small price to pay for bulk cleaning, P.D.Q

.

Good Luck Mick

You know, I think one thing that could be beneficial is some kind of compressible gasket, cut to fit and adhered to the sifter case. Just a bit of neoprene, for example, that compresses and seals any small gaps or misalignments between the sifter and the original case.

You could lay this out in illustrator or another vector program, and have someone laser it out.

In fact, Nicholas, if you’re interested I would maybe help you do this down the line- we have an engraver up to the task

(I mean a gasket that fits over every single individual space in the case, not one for the outer edges.)

H.P. Yes understood and appreciated, but ours was only a D.I.Y. Bodge (dont know if this translates to U.S. What would your expression be, Fred Carno,? Heath Robinson,? maybe) but if you look carefully at *Hamilton,s* professional Product not only have they factored in apparently higher Slats, presumably raised, to match the slight undercut of the normal dividers, in relation to the 4 vertical braces.

It appears also that they (Hamilton,s) have rebated the front riser to accommodate the Higher Riser that carries the Handle(s), by implication, almost migration proof, but our modest efforts were without any Yardstick, Hamilton,s B.P. and Transatlantic Exchange of Info were way in the future.!!

Ta… Mick.

Haven’t used one of these in decades! But the ones that I recall were all “home-made” by cannibalizing an existing case. Works really well for larger sizes of type (14pt. and larger) A real pain if you are dealing with small type though.

The “problem” arises in that the outer edge and the two main front-to-back dividers are higher that the individual compartment dividers and this allows the small sizes to jump or slip to a different compartment. A gasket of some kind to fill that gap would be the ideal situation for dealing with small types. You definitely want a tight seal when the “flip” is done.

As an added note, clamping the two cases together before the transfer is highly recommended.

Rick

Here are pictures of a commercial transfer case, no brand, but marked as property of ATF.

It has a removable frame that works with different depths of dividers, a rabbet for lipped cases, and also lips on the A-W cap boxes for slightly different length boxes.

First picture shows a side view close-up with frame in place; second is close-up with frame removed, and last shows transfer case with frame set loose on top.

transfer3.jpg

transfer2.jpg

transfer1.jpg

parallel_imp,

Thanks for the photos! I was wondering about how the caps side would work with different configurations.

Would you be willing to provide me with some measurements, such as the rabbet, removable frame, and lips on the A-W cap boxes?

What is the screening material and how is it adhered to the case?

We are in dire need for a transfer case for about 50 cases that are falling apart. We already transferred close to that amount already by hand but we are ready to pull our hair out.

Also, let me know if your willing to trade, lend, sell your transfer case.

I’ll do some measurements today.

The screen has a light frame behind it bradded in. I think you’ll need to do precise pilot holes with a drill press for that.

When I’ve tried to do brad repairs to cases, splits are bound to happen when the brad follows the grain. The rest of the fitting could probably be done with a table saw or a router: fine rabbets (yes, or rebates) and dadoes.

I’ve seen home-made transfer cases where the screen was just stapled in place, but for that perfect centering is critical.

OK, the main members of the case have been taken down to 1-1/16” (by 3/4” width). The box dividers are 3/16” wide stock for the vertical pieces and 5/64” for the horizontals.

The box dividers rise 1-13/32” up from the screen (here a metal screen) and rise 5/16” from the bare case side, or 1/16” from the removable frame.

Both the removable frame and the frame fixing the screen are made from 1/4” x 3/4” slats. The screen frame has butt joints and is nailed in, with additional box nails holding the screen against the box dividers. The removable frame has half-lap joints at the corners and cross laps for the two main dividers, and the joints are made with clinched brads.

The removable frame fits snugly, but you could also countersink and screw on the frame.

The lips on the cap cases are set flush, positioned at the bottom of the cases, made from 7/8” x 5/64” slats.

More images are attached showing the lips and screen.

transfer4.jpg

transfer5.jpg

transfer6.jpg