Blobby printing on small text

Preface: I’m a newbie!

I have been lucky enough to sometimes print jobs that had little to no problems. Other times (such as now!), I have issues I simply seem unable to fix. :[

Here’s the problem:

In the design of a card, I have text that is 9 points tall (Gotham)…Blobs appear within the small circles of B, 9, and so forth, while other, larger text appears fine.

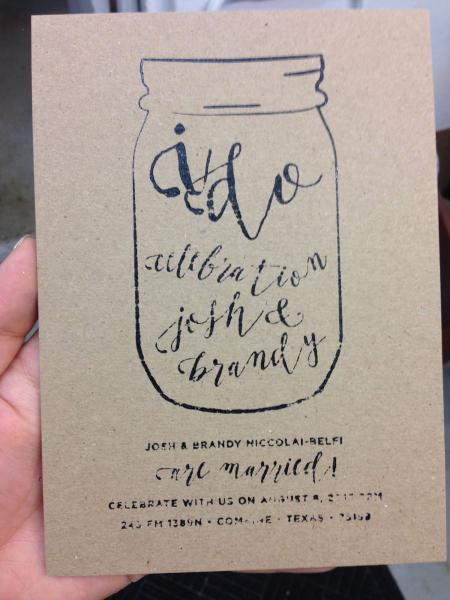

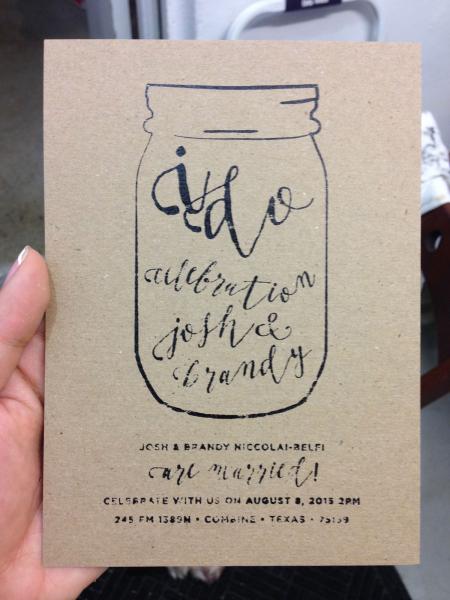

See images for examples of what I have tried and the best that it’s done. You can see that even with less packing and the chase adjusted outward, the blobs still appear.

Things I’ve tried:

- Checking roller height with the lollipop and adjusting as necessary.

- Removing or adding packing.

- Cleaning off my plate in hopes it was just dried ink.

- Running at least 10 prints to see if it would get better.

- Adjusting chase outward (meaning, less of impression) - the C&P has two knobs to do this.

The specs:

- Chandler & Price 10x15 Craftsman (1965; it is an automatic model, but I hand-feed it)

- Boxcar Base (Deep relief)

- Polymer Plate KF152

- Very new rollers (re-done by Advanced Roller Co. in CA)

I have strong suspicions my text was just too small. Gotham 9pt, measures at 2 millimeters as printed. I am really hoping the answer is not to get the plate re-made with bigger text. :(

0-Reduced_packing_adjusted_chase.jpg

1-Intermediate1.jpg

2-Intermediate2.jpg

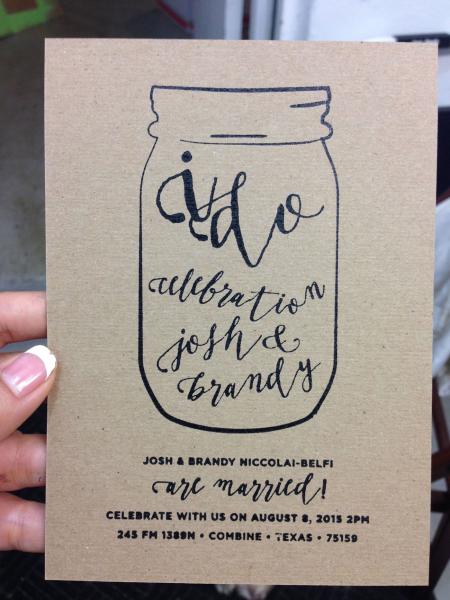

3-Best_with_packing_chase_in.jpg

After a decent design, it all starts with good inking. Without correct and good inking, all the other tinkering and adjusting and cursing will do no good. In your last photo it looks like the plate is mostly overinked. There is a spot in the T in Texas that requires further analysis. You want kiss inking while running with the minimum amount of ink. Add more later if required. The ink disk will tell you when the ink is right. If you hear well, it will sing (hiss). Not sizzle. It will also show a bit of texture. I call it velvet.

Ink press and ink plate. Remove chase and take to stone. Examine with magnifying glass. It should be uniformly inked on the face of the letters and not over the edge onto the beard. It must not be down in the counters of the letters. These are the closed loops like O and D and lower case e. The latter is the smallest counter. The other part of correct inking is correct roller height and pressure.

Only with this kiss inking can you go further and adjust the packing to get what you want.

Properly inked with a proper plate you should be able to print lower case e at 6 point.

Back to basics and you will do well.

Get some ink on your shirt.

With respect and in view of the *Things I have tried & Specs* as above, perhaps just ONCE Try printing on PROPER paper as an experiment.!!!

With the specifications as above, on proper paper You should be able to reproduce 5 point Type as in the Small adds from yesteryear, as good as and probably better than, Litho can do it now, i.e. First Generation Virgin Type on Decent/Proper paper or Card.

50, 60, more years ago here in U.K. we were printing everything from Business cards (admittedly on a Pirate Adana at home) to Multi page 4 colour Magazines on BIG American Meihles? Jo.Bergs H.Bergs Tirfings, etc etc

.

The point is that wether it was the little Bandit job at home or the Real Deal even 5 Pt. type reproduced perfectly on decent paper, from Virgin type, direct or reproduced for the Display Small Ads as 1/2 tone Zinco,s etc, on Art Paper and on a BIG Cylinder,s running 8,s 16,s even 32 page formes.

O.K. after 20,- 30,000 impressions the Type inc 5 Pt. was well worn, and still printing and usable but could NOT have subsequent updates inserted for Re-Runs, it showed up.!! on close scrutiny.

Many many years ago, it seemed a good idea to use BLOTTING Paper as the Tympan/Top sheet, (rather than under the Tympan) and inadvertently *Put one on the Packing* result = exactly as above.

With the specs as above, it should be possible to reproduce 5 Pt. Type or a line block, with the fine lines, even, that thin? crisp and clear inc. full points!

It does look like classic overinking. Start with a very small amount of ink and slowly add pea-sized dabs until the lines and type start to fill out better. Once you see the ink start to bleed off the type into the sides/impression area, you’ve got too much.

I also agree with Mick – try some different papers and see if that’s affecting the print quality.

Your last image looks to be about right in terms of packing, now work to get the ink right.

Also, to ensure your rollers aren’t sliding over the type, rub some rosin or dab some sticky spray (like Super77) on the rails. That will give the rollers some better traction, which will help when inking the plate.

Inky & Jonsel -

Thank you for your comments! I will clean off all ink and try again tomorrow.

I think you may be right:

On my last project, I under-inked. I may have over-compensated here, knowing I had more prints and more surface area.

Thanks — will post update,

JSML

Definitely too much ink is your problem; You can try pulling some ink off your plate without having to clean it completely by passing plain sheets of paper through your rollers on the ink disk when the press is running (be careful here).

No Emily. I don’t think that wise.

To remove ink place the paper on the ink disk and run the rollers over by hand turning the flywheel. It may take several sheets. Bond paper (copy paper) is probably the best. The rollers and ink may pull some fiber from newsprint.

It is called sheeting off.

It is better to start with too little ink and add more if required as it does not waste ink. Also saves the nuisance of sheeting off.

Too much ink is a common error with new printers. Perhaps good to make the error once. A learning experience.

Get some ink on your shirt

on setting roller height, as mentioned above I will ink the plate. then remove the chase and look at the type under a loupe to see if it’s inking just the surface or the shoulder as well. I’ve found quite often that what the lollipop says is good (1/6” stripe) is still too much on the plate.

By examining the inked plate with a loupe you will also see if you are over inked as you’ll see the “puddles” of excess ink in the more shallow counters.

FYI - it was over-inking!!!