Losing Detail and Sharpness

Hi Guys

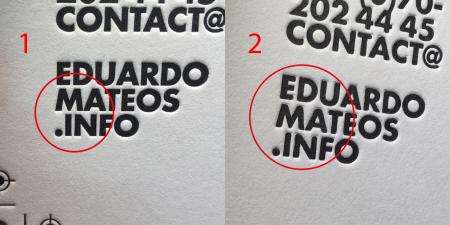

I have a huge issue with my Windmill, fairly huge anyway. I want to use heavy pressure on a thick paper, it’s a cotton paper (600g). I use photopolymer plate. The first few prints look good, see picture. But after a while details fall off. I’ve tried both low pressure and high. It is less prominent at low pressure, but still there. When I increase the pressure I lose detail quicker. It’s very annoying and my customer won’t be satisfied with either low pressure or losing detail. Does anyone have any ideas what I can try?

Does metal plate work better?

I’m greatful for all the help I can get.

/Johannes

print-work.jpg

First you must understand that your press and the polymer plate were not designed to do the heavy/deep impression.

If you wish to do the deep impression, you have to work with what the press and plate will allow you to do.

When you ink the plate, any ink that is over the edge of the face of the letters will be wiped off on the paper as the letters sink down into the holes in the paper. That makes fuzzy edges.

You must do perfect kiss inking to insure that only the face of the letters receive ink.

Some have tried printing with kiss inking and kiss impression on the first pass just as the press was designed to do. Next they remove the ink and pass the paper through again for an inkless stamping to create the deboss. To do this all impressions must be in perfect register. That rarely happens and you will have numerous rejects.

The Heidi is ok for deep impression but you have to think about the paper you are using in relation to the type of plate.

What is the paper made from? If it is made from new cotton fibre it will be soft, if made from reycled cotton rag it will be stiff. A combination of new and old fibre plus the size used will define the hardness. How easy/difficult is it to sink your finger nail in your stock?

Deep impression polymer plates are about 60+ sure hardness and have a wide base compared to the print surface so that as the plate sinks into the stock it acts as a wedge pushing the paper away from ink.

If you have to alter the impression on the run then either the plate is the problem or your packing is collapsing.

You could try steel backed deep impression polymer plates which have a sure hardness of about 90, or deep impression metal plates. It is deep impression metal plate and not the kiss impression/ hot foil plates required. The normal letterpress/hot foil have a straight edge and as inky stated the ink on the plates wipes the paper as it sinks in.

I am not a fan of deep impression, it is not letterpress printing, it’s just stamping paper.

For a recent customer I used a sheet of butyl pond liner instead of paper packing which helped get the impression required.

Has this been a frequent problem with the plates you typically buy or has it just started? I’d certainly contact your platemaker (unless it’s you!) and tell them the issue. They may have some suggestions. It’s hard to see much in those small pictures, but it seems like the plate itself is collapsing under the weight of your impression. Have you examined the plate itself up close? Can you see the corners mashed down or does it still look ok?

Hi guys and thank you for your comments and tips. There’s a small possibility that the plate is smashed. I’m not sure but I can’t see or feel anything on the plate that would consider it to be damaged. We don’t make the plates ourselves and I will talk to the company that manufactures them but they know little about letterpress, so I don’t know if they can help. But they do metal plates, so I should try that. But can I use the same Box Car base plate? I guess the metal plate (cliché) is thicker than the polymer plate, right. Any suggestions?

So the best way to get heavy pressure is with metal plate and/or to do a kiss print and then a higher pressure for round two.

All the best

Johannes