Ink Banding Vandercook

We are running into a problem printing flat areas. We seem to have isolated the problem to be either consistency of the ink or our forms rollers. We have used both a photopolymer and a linocut; we have turned the cut 90º and 180º; we have put the cut in different locations; we have tried transparent base and little ink, opaque white and a little ink, and a transparent ink out of the can; we have examined the tympan for dimpling; the form rollers were checked at about 3/32nds; but the problem still exists.

The form rollers are not new, but have been giving us great service on many other jobs usually more type and graphics without large flat areas. We are trying to print a very low saturation color that ideally we would accomplish with an extender such as transparent or opaque white base.

Has anyone encountered such a problem on their press? Any suggestions? Ideas to try? Tighter ink/looser ink? Ink roller up/down? Form roller to tight on the form?

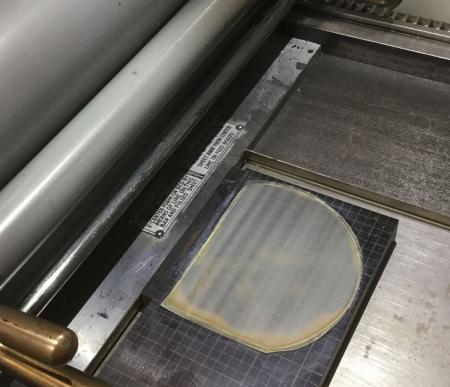

Ink banding on photopolymer

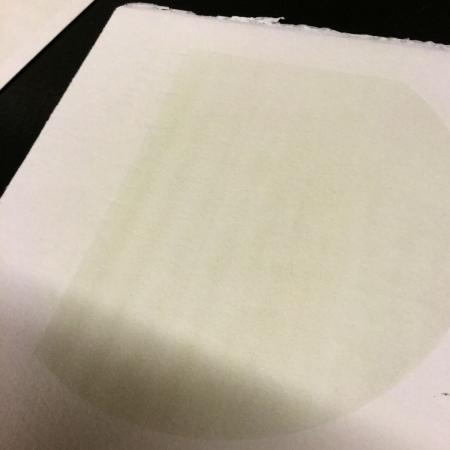

Banding on printed piece

Do the lighter bands correspond to the teeth on the gear rack? If so, I would guess that the rollers have shrunk from age and in order to set them low enough to get the reading you want on the gauge, the gears are now bottomed out on the rack. This could have the gears riding up going over each tooth of the rack essentially lifting the rollers as they pass over each tooth.

Arm—very interesting idea. I will look at that. Off the cuff, it seems like the bands are too wide to correspond to the gear teeth spacing, but perhaps. I just washed up the press, so I won’t get to this until tomorrow morning, but thanks for the suggestion. The best one so far.

I’ve never had this in letterpress but it is fairly common in flexography (another relief printing process). In flexo there are two types of banding. One is what The Arm said above, which is true “gear marking.”. The other is probably caused by the uneven displacement of the rubber in the form roller as it contacts the plate (or possibly as it contacts a metal roller). To explain why this happens, a little background is needed. Rubber (in this case the rubber in the roller) is incompressible. When the roller rubber is squeezed and pushed in slightly by a metal roller or the plate, it doesn’t compress; it displaces. [To visualize what is happening, think of walking in a muddy field. When you step in the mud, you don’t compress the mud, you displace it (it squeezes up around your boot). This is what happens to a rubber roller].

Since rollers must be adjusted to push into the form a little to achieve good ink transfer, you are reducing the space between the roller core and the plate which the roller rubber has to get through. Since the rubber isn’t compressible, the only way it can get through that reduced space is for the roller rubber to move a little faster when it is between the roller core and the plate. This can cause the rubber to slide slightly on the plate surface. Normally it does this evenly and doesn’t cause a problem. In your case, however, some roller rubber gets pushed up behind the reduced space between the roller core and the plate, and then when the tension gets great enough, it suddenly moves through that area with greater speed and causes the ink transfer to be different. It keeps doing this again and again, and that is what makes the visible bands.

I hope that makes sense….it is hard to explain.

To solve the problem, you might try making the ink more slippery, so the roller rubber can slide through more easily and uniformly. You might also try reducing the bead on your roller gauge, making a larger area for the roller rubber to get through.

Hi; I have a No. 4 (similar enough even if you have a No. 3) and- my suspicion is with the mechanism that engages/drives the rollers when they leave the feed board, and not necessarily with the gear rack itself. However, this involves the gears that interact with that rack.

The No. 4 has a sort of pair of gears that push together like a clutch transmission to release and allow free-spinning at the feed board (when oscillating via the drive cylinder/motorized inking), and which then engage and drive them when not at the home position; when at the home position, a plunger/foot sort of forces this mechanism open, but then they are supposed to come together and spin with the gear rack.

Look at the non-operator side of the form roller rack, at the gears that turn the rollers which you are already aware of, and you’ll see what I mean. Crank the press slowly and see if this is properly meshing, if not, it may need to be cleaned out and oiled to promote movement/engagement. Also, worth noting, my No. 4 doesn’t usually print well wen cranking too fast which I see as a result of this part wearing out a bit (I think I might need to replace them at some point).

It could be the springs are too loose, or that gunk is holding things up. Additionally, check the set screws on these as they may have either come loose or come out, causing wandering, but that is less likely to me.

. double post

Mark-

Is your problem when the gears are meshed or when they are supposed to be open? I have seen some presses where the roller clutch pins were worn flat, and also some where the brass foot that presses them was worn heavily. The clutch pins MR-110 are available new from NA Graphics. I had to replace some recently and the new ones were very good.

You will also notice that the wedge that triggers the brass foot has stacked shims behind it. Some minor adjustment can be made by adding a shim or two, but you won’t want to take it too far- it is better to replace worn parts, or braze and machine the wear on the brass paddle.

DGM

NA Graphics MR-110

Hey Dan;

My press runs well. My problem was that the clutch shaft was gummed up with oxidation/paper dust and wasn’t properly lubricated. Disassembly, cleaning, proper lubrication fixed the problem. (I think I worded my post a bit silly, as it makes it seem like the press we have is still problematic…)

But the OP’s problem sounds a bit like the gears aren’t meshing properly, and the fact that it’s at the start of the press/a large form makes me suspect it. Just another suggestion to add to the pile really.

Thanks for the info though about replacement parts!

When the roller gear clutch is the problem, there is an unusual noise as the radial gears clash before meshing.

I’m curious about your lockup method. Quoins and furniture? Magnets? The plate/base shown above is just laid loose on a galley; that could easily slip as the rollers move over it, and slipping could cause banding.

All good suggestions so far and the only thing that occurred to me was that the rollers may have some sort of problem in the bearing blocks—if brass bearing blocks, there could be excessive wear that causes the roller cores to bounce around while rotating, if the conversion to steel bearing blocks has been made, are the Nyliners on the end of the rollers cores intact and functioning properly? I am occasionally surprised that people are operating these presses with steel bearing blocks not knowing that the Nyliner is a critical component. They are sacrificial and do eventually wear out, but steel against steel is a problem that could cause the problem described and lead to expensive replacement of bearing blocks and roller cores. No. 4 cores new are over $200 each and a set of replacement bearing blocks with Nyliners is pushing $200 as well. This can add up to an expensive fix if not looked after.