Inking and pressure

Hi all,

We own platen Arab Crown Folio press and we are running into difficulties with ink coverage and pressure being greater on one side. We mainly print from photopolymer plates, using rubber based inks and mainly Colorplan or Fedrigoni paper - Materica.

Until now we were printing small artworks and had no many issues with it.

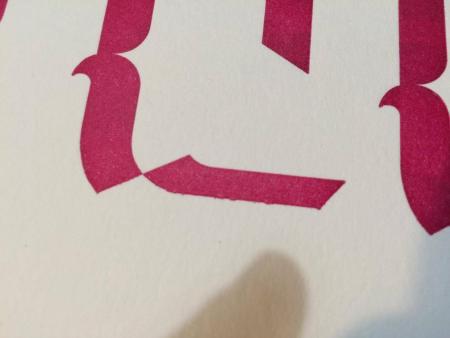

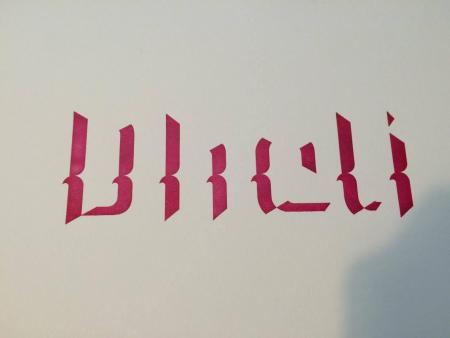

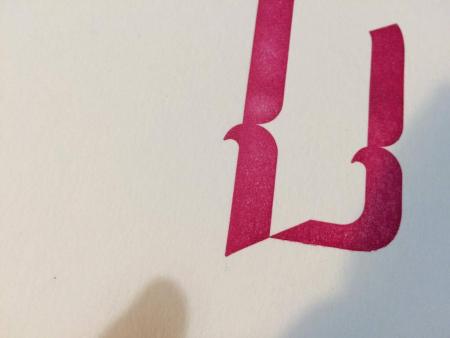

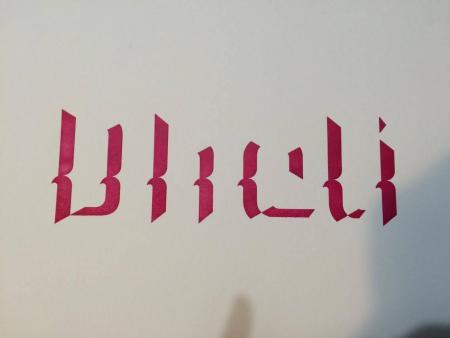

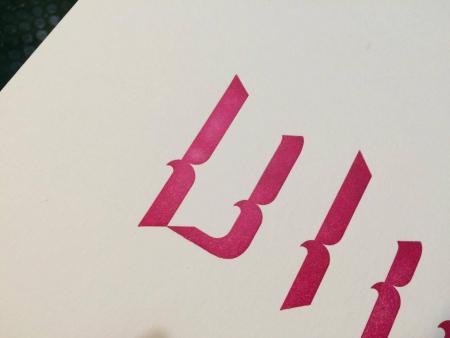

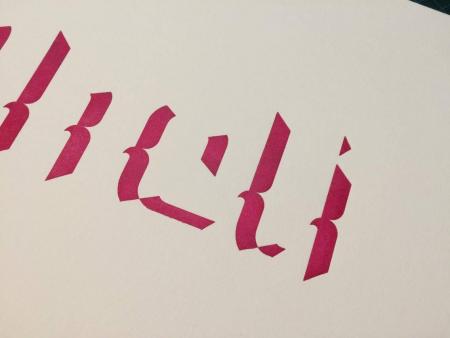

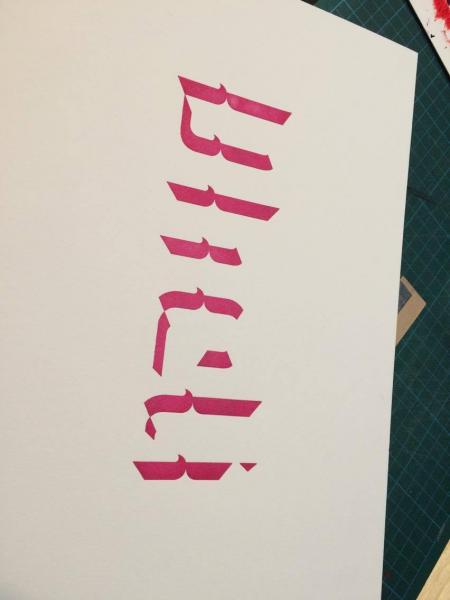

Right now we are trying to print bigger artworks onto B4 paper. Artwork measuring around 22 x 7 cm. Upon closer inspection we realised our press is not inking evenly and pressure seems to be bigger on one side. We are also getting some splotchy ink on some of the lines. The paper is attached without any movement and as typman we are using maylar which doesnt give us any movement.

I believe our rollers are set correctly as we are running rest with for letters attached in four corners. We think right side of the platen is more forward than the left one. By saying this I am little worried to adjust the back of the platen.

I am attaching some photos for your inspection. I would appreciated any suggestions, comments, advices.

Thank you.

24115494_10155874166773554_1532640261_o.jpg

24139371_10155874166433554_1922467006_o.jpg

24085471_10155874166663554_455295393_o.jpg

24085090_10155874166853554_873015606_o.jpg

24008097_10155874166888554_1138802472_o.jpg

24085123_10155874166978554_1855295043_o.jpg

24093866_10155874167028554_590353465_o.jpg

Theres also a funny problem with ink set-ups where two or three rollers ride up onto an intermittently revolving disc. Theres some sort of math that would explain it i’m sure,

but essentially a roller set get a trifle too much ink in the centre, and definitely too little at both ends, and the areas in between - on both sides - seem to get the right amount but those same areas are very prone to the ink doubler problem.

Three forme rollers better, two less so. Rider rollers, even home bodged ones, help a great deal.

If you are certain the base is sitting level in the chase and has nothing behind it to raise one side, the first thing to do is to level the platen so that both sides get the same impression. Once you get the impression even, you may find the color strength difference also goes away. If not, then you can get into potential inking problems.

But for now, you know the impression is not equal, and you should assume the platen is not level. It is a relatively simple adjustment, and one every press operator should know how to do, so go ahead and teach yourself how.

John Henry

Cedar Creek Press

Hi guys,

Thank you very much for booth answers. I am not sure about adjusting the platen on the back - just little worried as I am not experienced in it at all. Is this ok to do?

Harrildplaten to be honest I didn’t get what you saying but looked up for rider roller - didn’t find much about it.

Any other suggestion would be great. Thanks.

The platen on the Arab is not adjustable; it is the bed (where the forme sits) that may need adjustment by turning one or more of the four adjusting nuts behind the bed. A small adjustment produces large effects on the impression!

Hi Kenneth,

Sorry I meant bed.

Thank you for the answer. I will give it a try with four letters placed in the corner of the chaser and see where is the impression strongest. Most of the time I think it is in the bottom and top right.

I was reading somewhere not to mess with the big back screws - so thats why I am worried to do so.

Is it ok to do it? I never done anything like it.

Thank you.

Hi pressink.sk,

There is a way that you could kind of test if that is the issue before you do the adjusting. There might be other issues involved but this might shed some light.

Get some very thin paper, like tissue, and cut it to about the size of the base. Lay down a sheet and then lay down the next sheet on top of the first but cut it shorter and continue doing that until you have a sandwich of sheets that form a very thin wedge. You want to use just a few sheets. Then tape the wedge on the bed behind the base with the thick side of the wedge on the side of the bed where the ink is lightest on your print. If this corrects the inking problem, or at least improves it, then you may want adjust the bed properly to avoid the problem in the future. If this doesn’t affect the print then you might look to the rollers or elswhere.

Thank you very much Bruce.

I will give a it a try and it sounds like a good method to try.

Thank you.

Ok the test doesn’t tell if the bed or the roller is out of adjustment, you would first have to check to see if the bed and the platen are exactly parallel to know that as was said above. All this will do is maybe let you print the current job while you gather tools and knowledge. If after inserting the wedge you get a better print you probably won’t know if the plate is lifted to the proper position as though the bed were now correct or if the the plate is lifted high enough to contact a roller that is adjusted too high. But it is an easy little hack.