Lay bar - Heidelberg GTP platen

Hello,

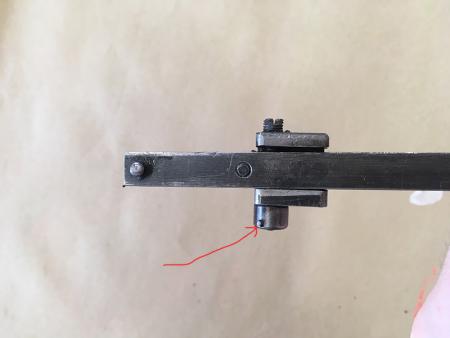

I have to replace a part of my lay bar (lay bar screw).

We can see it on photos. Does anyone know how to remove this screw ? There is a pin on the bottom but how to Remove it ?

Thanks for your help.

Thomas.

lay-bar-01.jpg

lay-bar-02.jpg

Not a Heidelberg person, but that looks correct on the pin. to remove the assembly.

You will need a drift punch to properly remove it. The punch will be close to the same size as the pin. A larger diameter will not work as the punch should be able to chase the pin through the hole if needed. A drift punch is flat on the end so not to enlarge the end of the pin. Look closely to make sure that the pin is not tapered, so to avoid pushing it the wrong way. It does not look so in the image.

A drop of light oil may be of help as well. As far as the screw. I cannot tell. You may post an image of it.

On the Heidelberg Press, doesn’t matter which one, all the Pins are tapered and machine set.

Appreciate the verification on the tapered pins.

Appreciate the verification on the tapered pins.

as stated above, be Very careful with these German “hieidy” pins almost all are tapered.

measure to be sure, they will be metric, but, you are looking for the taper. Unless you have a Very trained “Eye”, These pins are so small, I would use a micrometer on each end, to be sure.

it will probably be best to grind the narrow end off flush. Then use correct size pin punch to drive it out. Most will be on some sort of “flexible mechanism” so the impact doesn’t work much.

Tapping on it first, may work, but 99 out 50 times doesn’t. it will just mushroom it over.

Heat and Cooling cycles with Really good liquid penetrate IE: For steel is “Kroil” .

Good Luck…. Prob end up getting someone who knows what they are doing to drill that pin pin out. sorry, but, that is usually fastest answer.

Thanks for all your answer ! I have find the good end, I “just” have to find a pin punch…

on the other hand, that whole screw may just turn out? like with a special socket with 2 slots for those pins? are we over thinking this? can you just grip it with a locking pliers and turn the whole thing? I know a locking plier will damage surface and finish so, maybe a close fitting pipe with correct grooves cut in from the end?

Again, pb blaster, liquid wrench, kroil, even automatic transmission fluid. and some heat and cool cycles.to loosen