Kimble Motor-Friction Drive-Making it work.

My C&P 10x15NS came with a Kimble electric motor. This is friction driven with/out a belt.

The motor is 1/3 hp. CON. Duty Variable speed 500-2000 rpm. 110-220v looks to be .6-3 amps?

I have included a photograph of the plate. If anyone can see anything different, please chime in.

photo: Kimble motor label-2 and 5

The output end: Top side has a threaded cup full of grease. The bottom side of the bearing housing has a threaded plug. Someone on this list told me to put grease in the top and the cap screws down to push more grease into the bearings. I cannot get a view of the bearing type on this end. The comment to add grease and screw cap makes sense to me. I think during initial greasing that I would remove bottom plug. When grease is coming out of bottom hole, re-plug, add screw cap.

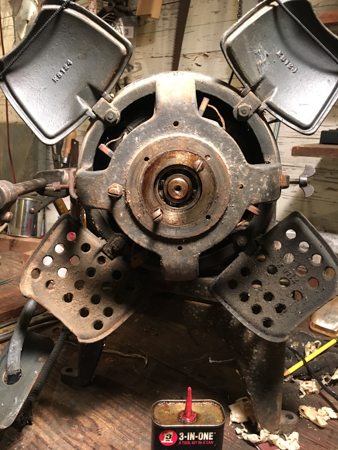

photos kimble-points of lube-front.

The (rear) commutator end: Grease is behind the control lever/cap on the rear of the motor. Screw plug in center feeds into a chamber to grease the bearings. I am thinking remove plug, add grease zurt, add a bit more grease and reverse the zurt back to a plug. The motor spins easily with no play in shaft. Any thoughts? I have been made aware not to over grease, but to grease often.

photos: rear control and rear bearings.

The motor looks good internally. Not too worn and the brushes look to have a lot of life left.

The wiring is fair. Wiring has been cut off with about 8 inches coming out of the motor. How should this be wired for power? Can I just use an off and on switch in a box. I figure I’ll mount it to the bottom of the feeding board where the original was mounted. Conduit of course. What should the breaker be for this motor? Should I ground the motor frame? I am not an electrician. Should this just be standard 110 volts.

I have interior shots if anyone needs. also see shot of commutator end with covers open. I love the look. Not using the 3-1 oil seen in photo.

The original instructions for the friction power, talks of a spring and cap that fits on the pedestal of the motor to help keep the motor wheel adjusted to the fly wheel. “ Place the pressure spring capped end up, between the recess in the base and the screw in the motor foot plate” Can anyone please post a photograph of their set-up and show me where the spring is to go.

No spring came with my motor. I can figure it out if I can just get a visual on it.

This is pretty much all that is left to get our press rolling. We will upgrade to a modern motor with a speed control as needed and as we can afford. All advice and photos welcome. You folks are the best.

Kimble_Motor_label-2.jpg

Kimble_Motor_label-5.jpg

Kimble_points_of_lube-front-cap-1.jpg

Kimble_points_of_lube-plug-front-1.jpg

Kimble_rear-control-1.jpg

Kimble_bearings-rear-1.jpg

Kimble_rear-open_covers-1.jpg

6 amps at 100v, or 3 amps at 220v depending on how you wire it

Hello! So glad I found your post. I was looking for help with my motor in regards to oiling. I just bought a C&P 10X15 and I believe we have the same motor. My motor has been squeaky and I don’t know how I would go about oiling it. Which points should I put oil in and what type of oil. Any advice?

Thanks,

Sandra

A log time ago here in the UK we had a six week long printers strike. The custom back then was that during a craftsmens strike the office staff - being non-union - would do what they could to keep the company going. Blacklegging, I know, I know, but it did keep the company afloat. Now a salesman called D.V, had been appointed to mind a Miehle Vertical and about four weeks in, came up to the office and said this machine is making a wailing noise. And indeed it was. And in reply to the obvious question came the immortal reply, ”oil, what oil” he never lived it down!

Anyone know where to get brushes for these old motors? Thanks for any info.

Helwig Carbon in the USA carries a number of sizes of carbon brushes.

Thank you for brush lead! Very Helpful.