Woodzilla Press- a cool little machine!

This last week a friend of mine mentioned that he had purchased a new small press from Woodzilla…. and he likes it a LOT. So today I spent a few minutes looking them up on Google, and then called my friend to ask him about it’s strengths and weaknesses.

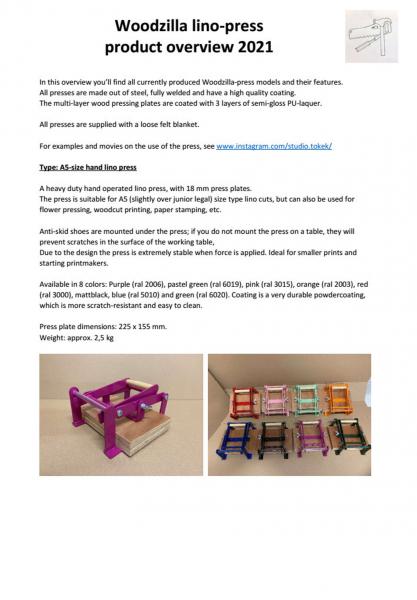

After studying it, I’m impressed! While it looks similar to the junky Speedball Lino press, it is in fact a whole ‘nuther creature. It’s made of real steel with AA faced hardwood plywood for the platen. More importantly, it uses a loose toggle mechanism similar to some of the old Adanas and will put down a lot more pressure. In fact, like and Adana or Kelsey, the mechanical leverage approaches infinite as the press closes.

It does not appear to take type-high blocks, but would work very nicely with PP plates, lino-cuts, or similar materials. It’s not a C&P or even a Showcard sign press, but it looks to me like it would put down a nice image. I’ve seen the results my friend have printed and they are surprisingly good.

Best of all…. it only costs $129 for an A5 sized machine! AND it comes in all sorts of great colors. I think I’m to order the red one!

The guy who sells it is on Etsy: https://www.etsy.com/shop/WoodzillaShop

disclaimer: I’m in no way affiliated with the vendor…. I just like this little press

woodzilla press.jpg

woodzilla2..jpg

All presses have something soft in their mechanism to compensate for small variations in flatness and thickness of the press components, the plates (or type), and the paper being printed on. In letterpresses it is the packing that is relatively soft, in offset presses it is the rubber blanket, in gravure presses it is the rubber impression cylinder, and in flexo presses it is the soft photopolymer or rubber plates. If this soft component is not present, you are much more likely to get skips in the printed image.

The following is just thinking out loud because I have no personal knowledge of the Woodzilla press, nor am I in any way affiliated with it. In this press, I guess the softness of the lino material, as well as the softness of the paper you are printing on, would be the soft component. However, if you were using hard lino or photopolymer, you might need to insert a couple of extra sheets of paper or a thin sheet of rubber to increase the soft layer.

I like the design, and it wouldn’t be too hard to modify it to accommodate a plywood chase so type high plates and type could be used with it. Just increase the height of the 4 legs.

It looks like a simple modification could be to carefully drill two precisely spaced holes closer to the platen in the bar it is mounted to, so that it could be raised that amount for higher material. 1 inch could be a good measure, with a sheet of offset blanket and.a layer of fairly thick mylar taped to the platen face. That combination might just put it in the winner’s circle.

Bob

Bob and Geoffrey…. you are right.

I thought the same things, and have pondered a couple of modifications along those lines:

1- add bails to the platen, just like on a Kelsey…. so I can use a tympan and packing. (or an old offset blanket)

2a- Drill the lower hole as outlined by AdLib to raise the platen to 1” OR

2b- make a slightly shorter bracket… depending on where the new holes fall in relation to the original ones.

3- add a 3/4” tall set of rails on either side of the chase-base with threaded inserts and screws, to lock blocks or a PPbase in place. I’ve added a similar lock-up to all of my homemade presses, so it’s an easy job.

4- add a gripper bar to the base. or maybe a pin-register bar.

With those mods, it would handle type high materials quite well…. and make a very handy little press for small projects.

Dave

aka Winking Cat Press

accidental duplicate post