C&P Kluge Press Identification Needed

Wow! What an amazing resource this is! Thank you all in advance for taking the time to provide those of us new to the letterpress world your opinions, advice and insights. As a professional calligrapher, and totally right-brained, I know this resource will be an invaluable tool for me (and my press operator, Dad) as I venture towards the great unknown.

First things first….. My C&P Kluge 10 X15 will be delivered to me next week. I have the model and serial numbers of the “Grasshopper”, but can’t seem to find that particular number listed anywhere. The serial number is NC855.

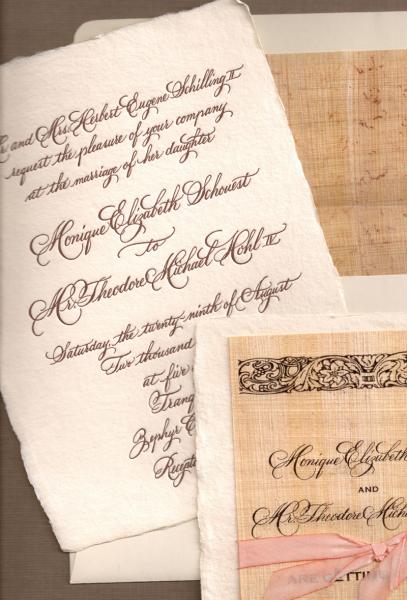

Second……I’m trying to figure out which type of plate will be best for my work. I’m contemplating buying Boxcar’s base, but am concerned about using a poly plate. The type of work I do consists of short runs but my artowork tends to consist of fine lines. I’ll attach an invitation I recently designed and had the printing commissioned.

Thank you kindly,

Kathryn

grasshopper press.jpg

schouest wedding.jpg

if you don’t want to use poly plates you could get mag plates from owosso graphics, that is what i use, their 1\4” mag dies, for mounting them i use wooden furniture, double sided tape on the back of the die then 2 pieces of chipboard under the furniture, most of my plates are small, this works well for me, you must make sure the furniture is same height if you use more than one piece. good luck dick g.

kathryn, your dad is a great asset. To my knowledge C&P

never collaborated with Kluge to make a press. Your question strikes an off note. Thats like asking a car guy

what kind of ford /chevy do I have? Load up on knowledge

printing and designing are 2 very different things. Your grasshopper will crush bones.best james

dick g — thanks for your reply. I think I’ll first try the mag plates, from what I’ve been reading, I’m concluding they’ll produce a sharper (and perhaps even deeper) image. I like your suggestion to mount the plates myself rather than pay owosso to set them type high. the mag plates are affordable, but the mounting seems a bit pricey.

James — I think you’re on to something!! I purchased the press off ebay and it was listed as a Kluge Press & Die Cutter. I travelled 11 hours to St. Pete’s to get a quick lesson on operating the press before it was packaged and shipped and noticed “Chandler & Price” was cast in the iron. The pressman told me Kluge at one time partnered with C&P. This was the baby of their 8 or so giant Kluge presses — all clearly stamped “Kluge”. Whatever it is — I’ll re-inspect it when it arrives and will let you know what I see.

Yes, my dad is an awesome asset as a retired engineer, and woodworking hobbyist, he’ll have a blast with the press.

I’m worried however about your “crush bones” comment. I know you meant that as a good thing, but, I have read that the clamshell type presses are dangerous. I’ve also heard there is a possibility of purchasing some sort of safety device or automatic sensor in the event your hands are in the wrong place at the wrong time. Any insights on that???

Thanks for taking the time to reply.

best,

kathryn

kluge used to make feeders for c&p so you might have one of these, looks like the feeder was removed. i have had a hand fed c&p since 1964, still have 10 fingers, if you stand straight and never try to reach into the press for a misfed sheet you should be ok, the c&p opens pretty wide compared to a golden, if you keep your back straight you should be ok, if dad doesn’t have experience on these presses maybe a lesson or two would be the wise thing to do. good luck dick g.

glad to hear you have all of your fingers. I’ll still play it safe and keep my calligraphy fingers out of the press and leave printing up to my guys.

thanks again.

kathryn

“The pressman told me Kluge at one time partnered with C&P. “

I’m having a similar issue with a press we just picked up…we thought it was a Kluge, but Chandler & Price is stamped on the platen. The serial number is similar to yours: NP445, and does not appear on any C&P serial number lists. I’m wondering if Kluge was just using C&P parts for some time, or if they were interchangeable as replacement parts. Ours also does not say Kluge anywhere on it.

Any idea where that pressman got that info? I can’t seem to find anything about it anywhere. Any help would be greatly appreciated!

Thanks.

here’s a photo of ours.

photo3.jpg

If anyone tells you of C&P and Kluge working together…that’s far from the truth. There was a bitter legal dispute in the ‘30’s over patent infringement. See http://search.aol.com/aol/search?query=Chandler+%26+Price+Co.+v.+Brandtj...

I notice that there are no rollers on this press. Cost, old prices, (three required): @ $80.00 to $175,++ per each (depends on composition or rubber) to be recast on YOUR cores. If you don’t have the cores, and/or roller wheels, add for those. Gauge pins, tympan paper, gripper fingers, wood furniture and cabinet, quoins and key, reglets, ink which is now very highly-priced now that it must meet OSHSA standards, a stone for lock-up all add up to a few bucks. For the looks of the scraps under the press it must have been used as a die-cutter. This means it could have considerable wear. Also the platen, if they didn’t use a die-cutting jacket, may have had some nicks and gouges in it from steel rule dies! Also, if dad runs the press, he should own it, as hiring or allowing anyone but the owner to run it, puts the liability on the owner!

The NP Series C&Ps were manufactured at the very end of the company’s existence, in the late 50s and early 60s. Somewhere I have a brochure about the model, I’ll see if I can find it. Yours looks to have had an automatic feeder attached originally, perhaps a Rice (it’s been several years since I operated one). This model is especially nice, because of the extra-heavy castings making it comparable to a Craftsman model and it has adjustable roller guides to get perfect inking. If you will figure how to set your feedboard higher you will be much happier, and if you no longer have the feeder you might want to remove some of the extra supports and levers that were used to operate it.

Paul

Thanks, Paul! If you do find the brochure, I’d love to see it. This info will at least help us in getting proper rollers and other parts.

And, thanks, Stanislaus for the link. Very interesting info on this topic! Amazing that a case from 1935 is online now.

Since your press is a 10 x 15 the standard rollers would be right for it. Link below for brocure for Model N. NP is probably a designation for the same press with a feeder.

http://www.flickr.com/photos/34564322@N03/4054364386/

Kathryn,

Who did you get your press from? Was in good shape? I’m heading to St. Petersburg tomorrow to look at a Kluge. I’m not experienced with these presses, kind of jumping in to it. The guys I’m dealing with say they will show me to to use it, etc. I just want know what I’m looking at is in good working order. Thanks!

I am running a 10x15 c&p press for printing invitations, business cards and misc documents. I am curious to see if I can add a foil stamping attachment to my press? What doI need to get it operational? Approximate cost$

IMG_9872.JPG

in a nutshell, kluge was buying C&P presses, putting their auto feeder on them and reselling them under the kluge name. this is where the infringement suit came in. C&P ended up losing and sold out to kluge, and at some point in there the brandtjen family bought into the bizz. this is where is stands today. Brantdjen & kluge. St. Croix Falls, Wis. USA.

Interesting conclusions—the cited Supreme Court case was 1935. C&P continued as a business into the early 1970s though the letterpress stuff went out of production in the early 1960s. C&P never sold out to Kluge.

Looking at the image 9872 I posted; does anyone know what the mechanism mounted on top of the machine is for? It looks like an inking well but does not make contact with the rollers or disc?

Jean

It is an ink fountain. It is bolted to the press in slots and can be adjusted to contact the top form roller when the press is on impression. The pawl that moves it is shown hanging down, out of contact; flip it up onto the ratchet to engage it.

C&P lost the procedural issue that was before the US Supreme Court in the decision that Ericm noted

However, C&P won the day two years later. The court’s opinion has a lot of detail the technical aspects of the patents, which may of some interest mechanical geeks! see:

https://casetext.com/case/brandtjen-kluge-v-joseph-freeman-inc

LD

Thanks for the info on the ink well!

Any information about foil stamping attachment for this press?