How was this delicate embossing/cutting pattern made?

Dear members,

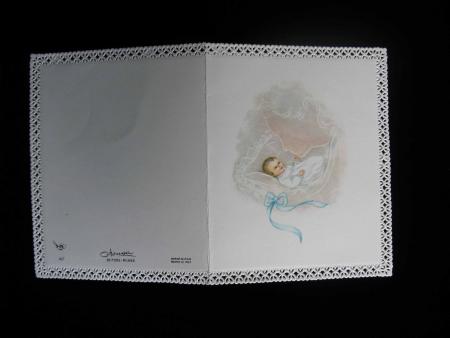

I am on a mission. For the first time, I feel the answer might be close by now that I am posting my question on this forum. For years, I’ve been looking for the technique and tools behind the delicate, lace - like pattern that was oftentimes found along the border of birth announcement cards in the 50/60/70’s. I’ve enclosed a picture of my own birth announcement card. As you can see, the edge has a design that was cut and embossed. How was this done? What tools/ parts would I need to make it myself on a letter press? Why is it not being made anymore? I have found a company, here in the Netherlands, that can laser-cut the design. I can have an embossing press made so I can get very close to the result that I want. However, I’m so intrigued by how it was done in the past and why it is so difficult to find any answers that I prefer to do it the old way! Does anybody know anything about this? I’m eagerly awaiting your comments.

Lydia

voorbeeld papier geboortekaartje.jpg

laser…and it is expensive.

I have seen paper like this at the restaurant supply store, in the pastry section. They use it as a cake base or to line pastry boxes. The restaurant supply is full of interesting treasures, actually!

It’s probably made on some kind of cylindrical punch machine. It might have a male/female die that perfs and embosses at the same time.

Hello Lydia,

I don’t think this could have been done by a laser in the time period you mention since lasers were not used for commercial applications like this until quite a while later. I’m guessing that Dr. Orange is right and that it was die-cut and embossed in one fell swoop.

A similar look — though certainly nowhere near as nice — can be achieved with a craft-store punch. It’s kind of a toy, the designs are limited, and it’s time-consuming, but it does work and it’s very cheap.

Barbara

Martha's decorative edger.jpg

Dear Barbara and Dr. Orange,

Thank you for writing!

I’ve seen Martha’s punchers and embossers, it’s a lot of fun, but you get nowhere near the intricate and delicate pattern like my birth announcement card had.

I’m curious to find out how these die- cutters/ embossers looked like in those days and it would be grand to find one (antique I guess) that I can use! I’ve been searching on the internet for a long time already, maybe I haven’t been using the right keywords to book any success so far since I lack knowledge about the printing world and all the tools/machines that were used! Also, the publishing companies (Mignon, Menga, Brakkenstein, Krüger etc) that sold those cards are now non- existent or they just don’t have anything to do with it anymore.

I’ll keep looking!

Here is a link to a paper doily machine manufacturer, showing the engraved steel roller they use to do the die cutting. This would be similar to a machine to make cards, I would think. The machine is roll fed, and there appear to be several unwinds because they run the webs together and then die cut several layers of paper at once to obtain greater production. They would then have to have a way of removing the little scrap pieces, probably by vacuum. Also, they would have to have a way of delivering a stack of die cut pieces, in a vertical or horizontal stack, or shingled on a conveyor.

http://www.alibaba.com/product-gs/211479279/paper_doily_machine_doily_ma...

I’m sure you are looking at six figures for a new one, plus more bucks for the engraved die cutting rollers.

A used one, maybe for scrap value, would probably be the only way a person could get into this. However, you would have to have a lot of space for a big machine, plus space to store roll paper, plus a lot of money to buy roll paper, and money to buy new steel die cutting rolls on occasion. If you didn’t have buyers for millions of pieces, this would probably bankrupt you in a hurry.

Unless you can find a way to approximate the old products with new technology which you can scale way down from a large production machine, it’s going to be very expensive, I think.

I had another thought about how this might be done. There are many tag and label companies which have presses with rotary die cutting units on them. One of their biggest rotary die suppliers is Rotometrics, and here is a link to them:

http://www.rotometrics.com/roto/WebContent.nsf/ProdElementLU/D310A8743F2...

If Rotometrics (or a company like them), said they could make you a rotary die to do what you wanted, then you would have to find a label company who was willing to order the paper and produce them for you. The label company would order the die for the make and model of press which they were going to use the die on. (These rotary dies will not fit any press like flat steel rule dies. They will fit the make and model of press they were made for, and my also fit a limited number of other presses). As a wild guess, you might be able to get the die for $1000 to $5000, depending on how complicated the design is, and then the label company might charge you $15 per thousand to die cut them, not counting the cost of the paper. (And, you would have to have a separate die for each design you wanted to produce).

The paper would have to be available in roll form, and the label company could help you with that.

If you want to pursue this, and need help finding a label company in your area, I’ll give you the names of the label company trade associations.

Hi Geoffrey,

Thank you so much for your input and help!

This definitely sounds like a way to try to go.

I will send an e-mail to Rotometrics with picture of the birth announcement card and ask them if they could make a rotary die to achieve such a design. I’m certainly interested to find out about suitable label companies in my area. I live in Amsterdam, The Netherlands. Do you think, this is how it was done in the 50/60/70’s as well?

Lydia, to answer the question in your last post, I think it was previously done on a bigger machine. However, a rotary die from a company like Rotometrics is probably a more practical way to do this type of die cutting now.

Edge decoration: Thank you Lydia, for posting that photo of your baby card. I have added it to my collection of 19th century cards, whose production techniques have not been documented. This lace-like appearance was (and maybe still is) popular and attractive. A rotary process similar to “Martha’s Edger”, that is a combination of thin flexible dies (used in envelope production to cut and crease and in self-adhesive labels, cut from the roll), and also in making the Anilox/Anaglypt/Ceramic rollers used in paper doilly/serviette, cameod wallpapers and other decorated or flexoed stock. Most of these can still be made, but are now CNC-/Laser-produced or chemically milled and thus very expensive.

If you really like “lace-like” edging on your cards, envelope flaps and liners, why not use “real lace”. I’ll post some photos later.

i have die cut slightly less intricate patterns on a heidelderg cylinder in the mid 90s some of the dies were from earlier than that and were flat bed type blocks of solid steel and appeared to be spark eroded .Repairs required that the die be milled down and the repair insert was fitted using countersunk bolts ,these cost horrendous amounts of money .

Some dies were later supplied to us using laser cut ply but not nearly so detailed however they too were hugely expensive to produce ,often containing thousands of pieces of rule these were for use as stencils for a product sold in america as either air art or blo pen cant remember which one was which country they were butterflies farm animals and such ,it would take some hours to make ready the machine and an error with wrong bedplate was not easily forgiven .

Wall paper was embossed on rollers and the spark eroded rollers also existed for die cutting on the web too .

There did exist machines that punched in a similar fashion to a pin perforater these incorporateda male and a female not unlike those that perfed stamps ,the embossing would be done conventionally as a second pass .

These were quite popular in Russia before the revolution.

vis08a.jpg

vis05a.jpg

vis01c.jpg

Sorry they are just a bit too old for me but i will enjoy the info chase !! Museum library here i come!!!!!