Missing throw-off?

After some photographic exchanges between another owner of a similar press, I’ve come to wonder if my press was, indeed, made with a throw-off and is now missing it. See the attached photos. I’m curious to know if it’s possible to have something fabricated. It would make life with this thing SO much easier.

One Manger Press's Samson 8x12. You can see the small throw-off lever in the center here, attached to the left arm.

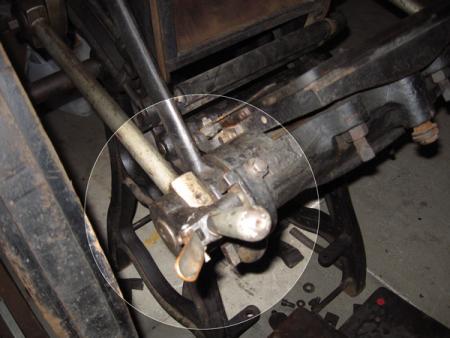

Here's my Samson without a throw-off. The bolt is obviously new (before I bought it, though), so I wonder if the throw-off existed but was damaged at some point and discarded.

Some of the older jobbers were made without them. I have a Gorham with no throw-off lever. Makes you a more careful feeder… :) If the press was built without one, you can not add one as the entire bed assembly is spaced off when the throw-off is engaged. Adding a lever won’t help if the press can’t move the bed assembly away due to original design.

Take a look at the way the bed shifts on the one you have with the throw-off. Visually trace the eccentric linkage from the lever through to the final action that spaces off the bed. Then look at the press without and see if all the linkages are the same or different. If identical, then you could find and add back the throw-off lever and eccentric and be in business, if not identical, it was probably made without.

I’m betting that it was made without, because if it was made with one, there would have to be vestigial remnants of the old lever and eccentric for the press to work, including something bolted in place to keep the press from spacing off and not printing.

Best,

Alan

Jonsel:

Are you certain you don’t have a throw-off? That lever and release on the casting at the front is somewhat similar to the throw-off on my Kelsey Union press. The shaft under the platen is an eccentric, and a simple release of the latch and turn of the lever accomplishes the throw-off by lowering the platen so it doesn’t contact the form.

John Henry

Perhaps I should have said “shaft behind the platen”, not under.

John Henry

John,

Which lever and release are you referring to? It seems there is one on the top photo (Samson with throw-off) but I don’t see that on the bottom photo (which, I believe, is the original poster’s actual press).

Am I missing something?

Brad.

Interesting. I was thinking the action was like a Gordon or C&P, but on the Samson the bed is fixed and only the platen pivots away. In this case, the throw off wouldn’t move the bed, but as John Henry notes, would unlock the platen and keep it from rotating into parallel before closing, thus preventing the impression. Given that the throw-off lever would move in unison with the platen, I wonder where you’d put the feed table so that you could get to that lever in a hurry… I’d hate to grab for that moving lever at feeding speeds since it’s swinging in and out with the motion of the platen.

I wonder if this was even a throw off at all, or has been mistakenly identified as such. Looking at the platen locking mechanism, it almost looks as if it was done to allow the platen to rotate to a flat position for make ready and insertion of gauge pins. On these presses where the bed is fixed, inserting gauge pins is a bit of a nuisance because you’re working in a narrow space, this would have solved that as well as given better access to the lower tympan bail.

Sorry if I didn’t make it clear. The top image with the throw-off is not my press. It’s Rich Hagopian’s out in Ohio. I’m here in NJ and the owner of the press in the bottom photo. Both Rich and I have done a little bit of web research on Samson, and it does appear they made it in versions with and without the throw-off. It was mainly the location of his lever and the discovery of the new bolt on mine that made me consider if something hadn’t happened in a previous life to lose the throw-off.

Alan, I sort of understand what you’re saying about trying to follow the action. This would be easier if I were in Ohio where the other press is located! I’m going to look at someone’s C&P the next time I’m at their studio to see if I can discern anything from it.

In general, I’m resigned to not having a throw-off, but I’d love to discover that it’s really there and I’m just too stupid to find it!

The feed table runs the entire front of the press, and sort of pops out and up on long gangly arms—perfect for snapping off in a move (the unfortunate case re: my samson; occurred prior to my purchase). You can see these arms going out in Jonsel’s press, just under the new bolt contraption. Mine (in first picture) are missing. The throw off is actually pretty discreet, and feels “cheap,” somehow, compared to my C&P’s.

rich

Ah-HA, now I understand. I was indeed confused.

Jonsel:

If you have the opportunity, remove the cap and the side arm and see if the shaft is concentric or eccentric. If it is eccentric, it was intended to have a throw-off. If not, then it wasn’t.

Rich,

Can you post a photo of the lever in both positions and the corresponding position of the platen?

Best,

Alan

John Henry,

I know this is a totally geeky engineering rathole, but can you post a picture of the throw-off from your Kelsey Union? I’ve seen throw-offs on Colts Armory class presses and Gordon style presses, but this eccentric and throw off for the Kelsey fascinates me. Conceptually I get how it would work, but would love to see the image. The myriad ways that a problem can be solved with engineering never cease to amaze me.

Best,

Alan

John Henry,

I sort of ran up a diagram, is this how your throw-off works? Also, for the curious, here’s the wikipedia entry for eccentric which also has a link for concentric.

http://en.wikipedia.org/wiki/Eccentric_(mechanism)

Alan

platen eccentric throw off diagram.jpg

Good idea, John. Time for some exploratory surgery!

Wow, John. That’s impressive.

That’s more or less how the throw off *seems* to work.

It’s composed of three parts, it seems.

a) The lever unit, which attaches to long steel shaft

b) An exterior cast iron housing that the shaft sits inside, which is connected to the platen as one unit

c) A small unit that bolts onto the cast iron housing.

The small bolted on unit is critical for the throw off to work. How do I explain this?

I’ll post three pics. The first is the throw off disengaged; this leaves 1/8 space between platen & bed.

Second is throw off partially disengaged. Notice the hole at the top of the small unit (c, above)? At the throw off’s full engagement, a small, spring-driven piece of metal pops into this hole, which locks the throw-off in place. As the throw off is raised from bottom position (disengagement) to top (engagement), you can feel the cast iron housing that the steel shaft sits in & is connected to the platen move up & closer to the bed just a little. It’s not much, but it does keep platen & form apart.

disengaged

IMG_4502.JPG

halfway engaged

IMG_4504.JPG

engaged

IMG_4503.JPG

So.

Some follow up.

Reverse the whole “engagement” “disengagement” language; when the throw off is “up,” the platen will meet the type, when down, it won’t.

Also, yes, those are hand-canceled stamps that I should have sent Phil Ambrosi a year ago. My bad…