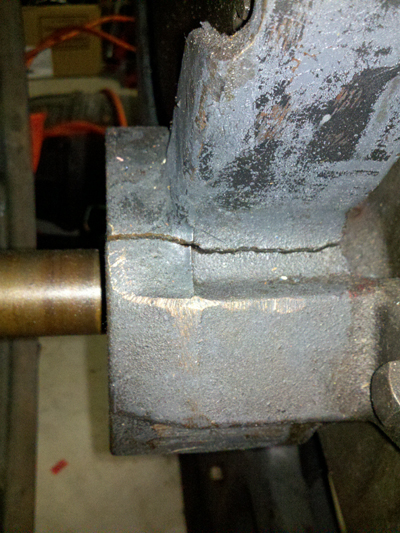

Purchase press with crack?

Hi There,

I am looking into buying a C&P 8x12 press that has a crack in the frame. I’m a complete beginner so I need someone to look at these pictures and tell me whether or not I should be concerned about the crack. My father is an experienced welder so he may be able to fix it. Would that require taking the entire press apart? As I said, I’m a novice so I’m welcome to any and all advice. Thanks so much.

1a.jpg

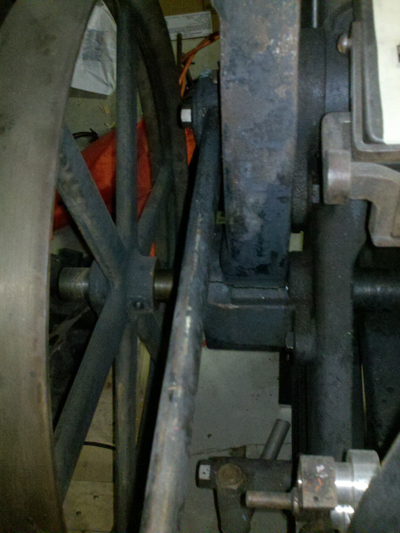

5a.jpg

6a.jpg

Ask your Father if he can weld (or braze) cast iron - it’s not as easy as welding steel.

Yes, it should be taken apart, and the need for repair should have an big impact on the price of this press - otherwise it’s not really safe to run.

And ask how it was broken like this - doesn’t look easy to do…

That part is not something that is usually broken. Like Bill said ask how this got broken, it looks to me like the press might have fell over. i would check the whole press very closely. Dick G.

That press possibly may have run like that for fifty years…and may run another fifty…but not for me. I would say be patient and wait for another, or start out with a tabletop, it’s a lot easier to move and for a beginner, it’s a lot easier on your fingers. Don’t forget all the stuff you’ll need to get started. Type, cases, furniture, motor, treadle, quoins, ink among others.

#Stanislaus - I find it hard to imagine how that bearing would have remained lubricated for those fifty years.

8)

In my experience, welded cast iron does not hold. I’d pass and wait for another press.

I’ve been watching too much “Breaking Bad.” I thought someone wanted to exchange crack cocaine for a press. I knew the market was hot, but I’m sure Elizabeth would delete such a request.

:-)

Barbara

As someone who just bought a press…..I’d wait.

I payed a lot more for my press than the norm, but it had new rollers, it was mechanically sound and working fine, and was shipped to me by the seller directly…..God is good!

I was really really tempted to buy a Golding, but this one in particular, good price, free shipping had fixing needs……

I figured that I better not be tempted with a fixer, bcs I can’t fix mechanical things, and it turns out a lot that you always pay more for something to be fixed than its probably worth.

Thats my input.

Barbara, I was going to say something much along the same lines, but I refrained until now…LOL!

mirmandy, I’d pass on this press also. It could be fixed but why does it have to be by you?

It seems that the real bait here could be that it appears to include what seems to be a Boxcar base, and that could be a consideration if the price on the entire package is reasonable (IF it IS included).

I’d wait…but it’s your choice…and your Dad seems like he may be competent…so just weigh the decision out.

Pilgrim, that post makes it sound like God sold you your press, i didn’t know he sold equipment.

Looks like a press that should be parted out, probably make way more money that way anyhow!! Let me know, there is a part I need!!

LOL Dick! Actually the seller was Mennonite and there was details of the sale only God couldve worked out! So, yeah, He doesn’t sell stuff, but when you ask Him amazing things happen—true story with no embellishments!! :)

That crack is in the gear guard on the front right of the press. It’s nothing structural nor does it have any mechanical function on a hand fed press. I would have no hesitation purchasing the press if that’s all that’s wrong with it. At the bottom left of the last photo you can see what appears to be the bracket that holds the gear cluster of a Kluge autofeeder. My guess is that at some point it had a feeder on it and the “pole” that holds the feed arm was bumped into a door frame etc. during a move. As the gear guard acts as a structural member for the autofeeder you don’t need to hit the feeder very hard to crack it at the mounting points. I owned a kluge/CP with the autofeeder bracket and gear guard both cracked and rewelded. Ran great. Hope that helps.

I kind of agree with #nervous_john - the press is not unsafe (if repaired, IMO), and can be easily welded by someone who knows how to weld or braze cast iron. And if it happened as #nervous_john suggests, then the rest of the press should be fine - and you should be able to pick it up inexpensively.

Nervous_John: Please note this is on the left side of the press and there are no gear guards here because there ain’t no gears here. This press doen’t show any sign of a Kluge feeder ever been attached to it. Also anyone who has seen an 8x12 Kluge feeder please ring in and enlighten us.

Nervous_John: Please note this is on the left side of the press and there are no gear guards here because there ain’t no gears here. This press doen’t show any sign of a Kluge feeder ever been attached to it. Also anyone who has seen an 8x12 Kluge feeder please ring in and enlighten us.

it seems that this guard is covering the pinion gear, and as stated above would run a long time without problem. IF this is the only problem. check it over closely. check the raceway in the big “bull gear”. any thing weird in there means trouble.

Man, you’ve got a good eye nervous_john.

The 3rd pic is looking from the back to the front, and we are not looking at the flywheel but the drive pulley.

It is the guard covering the gear.

Again, I must step into my orthopaedic shoes, and stand corrected. It was the first picture of the flywheel side that confused me. But I’m still waiting on reports of an 8x12 Kluge out there someplace!

I’m guessing Kluge feeder for two reasons. First- in the last pic just to the left of the saddles and to the right of the dog bone/arm you’ll see a small grey metal piece with a bolt on the end. It looks like the main frame piece for the feeder’s gear cluster. This bracket tends to be left on after the feeder is removed because the bolts that go through it, the outer frame, and thread into the inner frame arm are about an inch too long if the bracket is removed. Second- the press has two flywheels. Every C&P or Kluge with two flywheels that I’ve seen has been autofed due to the reasoning that the second flywheel helps add impressional strength for die cutting. They could have added a second flywheel later but it seems fairly unlikely.

Mind you I could be completely wrong about the autofeeder but it makes for some interesting discussion and speculation!

Still doesn’t solve the mystery of a non-existent Kluge feeder on an 8x12 press.

Wow, thank you so much for all of the feedback. I really appreciate it, despite the fact that I have no idea what you’re talking about with this Kluge feeder discussion.

My dad has welded cast iron before so now I just have to decide if we actually want to try to repair the crack. Anyone care to suggest how much they would pay for a press like this?

Barbara: That is hilarious! I supposed I should have said, “with A crack” instead of “with crack!”