Windmill help!

Hello All - I had a functioning mid 50’s windmill that I just moved to a new location. I had no problems in the move. Now that it is set up in it’s new location, one of the roller arms is stuck. I can force it in or out with a hammer, but it does not return to it’s normal position with the spring alone. I have no idea what happened or what to do. Anyone have any advice?

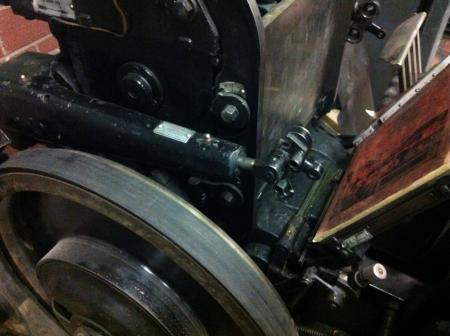

handbillrollerarm.jpg

handbillrollerarm2.jpg

Sounds like the roller arm is bent. In the move someone could pushed on roller arm.

Are they available as a part? Are they hard to replace? I don’t even see how to get it out of there.

Yes. Call Whittenburg or Demer’s and be prepared for the shock of just how expensive Heidelberg parts (even used ones) can be.

Not sure how difficult it is to replace but I don’t imagine it’s too hard.

Brad.

detailed description of your arm and i may have one but the two i am looking at are from a steel ball model that may make it too early i need to know the length , the diameter and a description giving every detail you can . i am rather frightened re the shipping of them as its grey territory to me and the uk is hardly on your door step. Never having bent an inner arm that i could not re straighten i dont know what they are worth but if you find it cost telephone numbers as we say i will help and you can make an offer based on the briar press folks advice . I am not a dealer i do a lot of work on and around letterpress kit much of what i have is from cannibalising machines before the scrap man could get it . the doing of this has enabled me to learn more about the kit i use . As your arm is probably shot you

could lay into it with a rubber hammer of large size i have straightened a few this way without even having to dismantle the arm which from experience is not the easy job you might think , more damned taper pins. have mailed you direct with a suggestion if you have not recieved it let me know

This is very interesting because exactly the same thing happened to me, my Heidelberg platen arrived with the arm stuck after being moved. You can see the story here:

http://www.briarpress.org/27176

Hope my pain eases your solution. Message me if you need more info.

Nick.

peter, aaron and brad - Thank you for the good advice. Peter, the way you describe it actually seems doable. Thank you for going into such detail. I will probably try to tackle it early next week. I’ll let you all know how it goes. I still don’t understand how it could have gotten bent inside of the housing. I should have taken the rollers out for the move, but I didn’t. I guess it is possble that they were extended and got bumped, which would make me thing the bend is on the front of the arm. there is some damage to the bushing on the end of the roller on that side.

you have given me hope. thanks

jason

I bent one on the pump side whilst installing it , we were putting it down onto the plate and i was not familiar with a single knob operating forktruck . we had it against a wall and the upper portion of the wall was further back than the lower portion, i meant to lower it down and i tilted the thing instead, the arm caught the ledge created by the wall having a thicker lower portion , one of those very embarrasing moments !!!!!!

If you have visible damage you will know where to start your operation , as that will be your point of impact , . I am due to remove an old one from a printer s in the near future ,sadly again , its destined for the scrap yard , i will try to get what i think are the most often requested damaged bits off her before she goes but i will probably only have a limited time to raid it , however i will try to cut the shaft with the complete arm assemblys on it iknow i wont have time to dismantle via the dreaded tapers , i have ghanged whole assemblys and yet to come across one that the pins werent dog legged in there .