Installing On/OFF Switch on Variable Speed Motor

Hello folks. I’ve got my press up and going for the most part except for one thing - hooking up the switch to motor. Everything else is good and I know the motor works because I saw it running right before I bought it, but the seller un hooked the switch to prevent it from getting caught when moving and now I don’t know where the wires go!

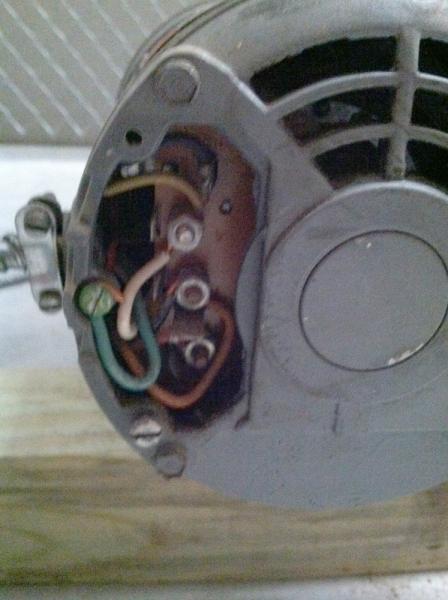

Here are some pictures of where I THINK the wires might belong. You can see I already hooked up the plug head (that was easy, and labeled so I feel sure about that). I assume they go here because it is the only place on the motor where slots/holes exist to let the wires through, that and it was the only screw that turned easily so I know the plate has been removed in the past.

Does anyone feel comfortable explaining this to me? I assume it’s a pretty simple thing.

The Motor Brand

The plug hooked up and taped

The two wires in question that come from the On/Off Switch

You can see here that the three wires which go to the plug are wrapped up - green for grounded and then white and black

Here you can sort of see the slots/holes where I assume the wires go into the motor

About wiring a motor:

This is not intended as criticism, but in our country electric supply is variously 230 to 250 volts, and if 3-phase, is called 415. I could not read any voltage on the picture, but presume it is 110; when we had a visit from U.S friend, he was very cautious about handling his shaver (110 to 250 volts, self-regulating) when he plugged it into our power outlets; after discovering how U.S. allows 220 volt equipment, I can understand why.

I wonder how the ground wire is connected to ground (we call it earth). Even in Australia, there can be problems with grounding, I have heard of electric hot-water systems which give “tingling” showers because of grounding problems.

Do not try this at home, but I wonder what 110 volts feels like? My 2 sons are electricians, and very cautious, but one says he saw the long white tunnel with the light at the end, then his body reaction to electric current threw him off the ladder and the impact re-started his heart. I myself took hold of 385 volts a.c. in a wireless (radio) receiver, never repeated the experience. I once saw the list of body reactions to various intensities of electric current, I wonder how they found them? Some Australians (surf life-savers) allowed themselves to be drugged so as to allow measurement of the various kinds of resuscitation, the result was an advance in how mouth-to-mouth and cardio-pulmonary-resuscitation is taught; naturally under the best controlled conditions with the appropriate medical personnel supervising.

Alan

Alan.

.

A quick google (is google a verb now?) on the info from the nameplate suggests that your motor may well be a take-out from a larger unit, a Dayton 5K994 Adjustable Speed Drive (if I’m reading the photo of the nameplate correctly - its a bit fuzzy). Dayton is just a brand name used by Grainger now; you can see this unit if you go to http://daytonmotors.com/ (which is a Grainger site) and plug in 5K994. This unit is no longer in production, but you might want to contact Grainger to see if they have a schematic for it.

Regards,

David M.

Thanks, gentlemen. Here is a more zoomed in photo of the plate. I only had my phone on me at the time so the photos are terrible.

Alan, I certainly don’t want to be electrocuted! If this is something beyond my ability I have no problem paying for assistance. I am cautious about plugging in the cord… I watched some videos explaining it and talked to someone about it before hooking it up, so I hope that part is ok.

David, That does look rather like my motor - if a more modern version.

The gentleman who owned the press before me had it for something like 30 years or more. It may be quite an old motor for all I know. I would never dream of hooking it up myself if he had not shown me it working and all the parts were not already there. I just balk at the idea of paying someone a hundred dollars for something that probably takes five minutes - it seems like it would be a waste of time for both of us and he’d probably laugh at me for something so simple.

The volts look like 115/ 230. It’s in the bottom right I think…

volts.jpg

New motor $200-$700

Friendly spark $100 dollars ! Doesnt needs much thinking on really .

Peter is right — if you don’t get it right you could destroy the motor and possibly electrocute yourself. Better to either get an expert to wire it up for you or research the wiring schematic thoroughly. Normally the frame would be the neutral side (white wire), also grounded (green wire), and the windings the hot (black wire), with 120V, but it would be best to have a qualified electrician do it to be sure — with correct info from the motor specs.

Bob

Often the schematics are on the back of the cover you removed.

I’ll find an expert to help me. When I asked someone they said that at worst I would blow the switch which is inexpensive to replace but if there is any risk I’ll damage the motor or myself, the money seems worth it.

Also, I did see schematics on the plate I removed, but I didn’t understand them.

I’ve tried to contact the guy I bought it from because he is local, but I haven’t heard from him (he is a busy man, but very nice)

You showed everything except the switch itself.

From what I can see in your pictures, the motor is already connected. I assume that the wires you are holding in your hand are coming out of the metal sheath that is connected to the motor? If so, the motor is all hooked up. Put the cover on and leave that alone. The black wire in your hand goes to one leg (terminal) of the switch. The black wire from the plug goes to the other leg of the switch. The white wire in your hand goes to the white wire from the plug, most likely by means of a wire nut tying the two together inside the switch box. The green wire goes to the green wire of the plug which is the third or ground pin. I see the green wire hooked to the case inside the motor but I don’t see it in your hand. Did someone chop it off? Not the best practice but not uncommon. The green wire should connect the case of the motor and the switch enclosure (if it’s metal) to the ground pin of the plug. This prevents you from becoming electrocuted if you miss wire something or if something shorts out accidently.

Learned friends dont seem to be able to see the wood for the trees, regardless of 110 or 240 it has to be A C (alternating current for the above learned friends) which by its very nature tends to invite vibrations, and consequently and normally involves shake proof (serrated) washers on the wires attached to the internal fibre! distribution panel , which carries the links, to alter the polarity and the rotation, the incoming wires would never ever be single strand solid wired type cable as illustrated (Yuri Geller would rub those in two in 2 minutes flat) Here and even in the USA, I am sure, a reasonably profficient sparks would install at very least 2 core multi strand (live and neutral) with armoured casing which includes earth, to earth on the appliance and then include soldered on spade connectors, to the terminals. Crimp on ones with chemicals leeching in are not the best idea, single core wrapped round is about as low as you can go, especially if the motor has to describe even the smallest arc in operation for tensioning. It would then be normal for ease of use and for safety to see the wires from the motor coming back to the most conveniently placed stop/start isolator which has the internal trips set to exactly the correct factor to protect, The Operator, The Motor, and the supply.

Musikwerke,

I think you may be correct. The switch has the two wires- white and black coming from the switch itself (were already hooked up to the switch - just not the motor in any way to be effective) … There is no ground wire coming from the switch which is currently screwed to the underside of the delivery board on the front of the press.

One thing I noticed was that the white wire is sort of a spiral coil - so it definitely looks like it was wrapped around one of the other copper wires because the diameter of the spiral matches that of the copper wires. It would also make sense, because I think the owner took the plug for another press he had- if the switch wires go down to the plug too it would explain why they were unhooked in the first place. If they were supposed to connect to the motor somewhere I’m not sure why he would have unhooked them ( I was assuming he disconnected them to keep then from getting yanked but I don’t know for sure)

I honestly cannot find any place where these wires could even go if they don’t go straight to the plug or to the open panel shown - but everything in there is dusty and very tightly wound so it doesn’t look like he has messed with it (thus I assume the wires didn’t belong there).

BTW the wires I’m holding come from the switch - not the motor. The ones from the motor are hooked into the grounded plug

.

What you have is not a complicated circuit to hook back up. If you want to e-mail me photos of everything so that I can see what’s hooked and unhooked, I’ll be glad to sort it out for you.

Thank you, I will take high resolution photos and send them to you. I have to go measure the platen tomorrow anyway so I can cut down some Tympan for it. I’m assuming it’s really just a matter of closing the circuit. I made sure the metal housing/wire guard for the switch touches the press (the wire guard is zip tied to it), to ground it also but I’ll make sure it’s all photographed for you.

This is so wrong on so many levels that I despair of the typing required to explain it. The motor terminal box is not designed to be a splice-box. The metal wrapped cable (BX) is meant for fixed application (not plug in). The plug wiring is an explosion waiting to happen in your hand. If you are willing to spend a few bucks on a splice-box, some connectors and proper cabtire cable, drop me a line and I will explain the way I would approach it.

With respect is this not exactly what I submitted on the 12 of November in fairly comprehensive detail, admittedly I am not in command of minute details, as applicable in USA but I have wired 2 print units for 3 phase, which includes single phase, (obviously), and have been issued with a certificate of complyability by our local electricity supply company without question. And over the course of several years, have wired /rewired Heidelberg Platens, Thompson Platens, V/M,s Many Monotype Composition and Supercasters etc, obviously working to current regulations, (English) and have used originally, steel conduit with individual phase wires pulled through, then black Hi-Tuff (which is triple insulated with rubber glands to keep out all of the undesirable liquids that usually accompany printing presses) and recently Piro, which is mineral enclosed copper sheathed and plastic covered cable, which has to be assembled with 3 part adaptor kits to assemble end fittings, and which has been/is used on filling station forecourts and Printers Chemical stores because it is 99% proof against sparks etc. Is it just possible that my previous post may be worth re-investigating?

No worries all,

I consulted a veteran electrician (who happened to be the father of a friend, who knew) and he said the wires definitely went to the plug previously but it isn’t the proper way.

Additionally, he seemed so excited to see the press he has offered to come and hook it up for free (he is retired, bored and refused payment so I offered some free custom business cards as thanks) He says he can get the switch to go the motor which will be more orderly and safer.

I will no longer be in danger of electrocuting myself. Thanks for your help, I’ve learned a lot about something that has always been foreign to me.

This looks like Panther Press was lucky; others please take note of his experience.

Alan.