ink coverage issues (striping)

I’m having issues with my ink coverage. There’s a stripe of my plate toward the bottom that’s not getting ink coverage, despite re-inking the disk. I’ve inspected the plate (it’s level), the rails/rail tape, my trucks, and the roller height. the impression is fine, it’s just not inking in this one strip.

Rollers are a few months old…could they already be flattening enough to cause this?

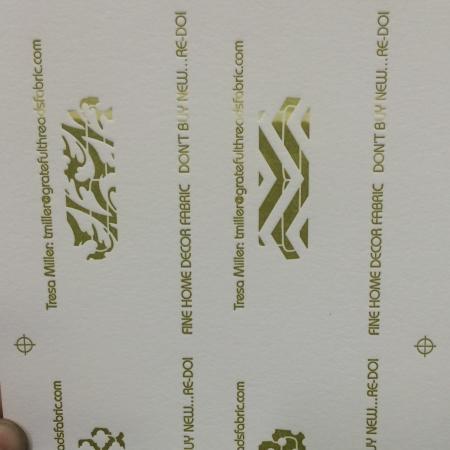

Photos below! Thank you!

image.jpg

some details that might help:

hand-fed c&p new style 12x18, using a deep impression base/plates on crane lettra 110

Hi- is this the lap mark, by any chance?

newbie here! what’s a lap mark, and how can I fix it?

n

If you leave the ink rollers up on the ink disk that can cause a flat spot. Or using something other than Roller wash or blanket wash.

Do you have enough room to try turning the artwork 90 degrees in the chase?

DGM

Cassie-

Lap mark as I would explain it; roller is round, therefore a circumference. 3.14*roller diameter determines circumference where lap mark would occur. SO, if you are running a roller that is 1.25” diameter, for example, it can run 3.925” approx.. before repeating itself.

If you have a form that is longer than 3.925” with a roller of that diameter, you will see a ‘lap mark’ show up where the roller has first hit the form, let go of ink, and then the portion with the ink missing comes back around and transfers less ink to a new portion of the form (plate, type, whatever).

When you have multiple plates lined up in a row and they are at the sweet spot distance and stay inside the roller’s un-lapped area, all is well….

…. but when something drifts out of that sweet spot sometimes you can see a banding issue with more transparent inks that are not as potent.

There isn’t a lot you can do to fix this aside from use a smaller plate, print single-up, etc.

But on closer look it could be a flat spot, and if you’re operating a press and leaving the rollers on the disc as others have suggested it can be a problem.

You can try rotating the roller with your hand and see if the strip moves to another spot.

You can also try switching to another plate but be sure it goes to the same place over your base and see if it is a problem still.

Am I remembering right that the 12x18 C&P had a provision for rider rollers on the form rollers? If the issue is the lap, riders would, I should think, fix that, but they would probably not be easy to obtain. And judging from the nature of the un-inked area in the photo, its edge is a straight line across the form and is more likely due to a flat spot on the roller(s) than a lap issue. Another possibility is inadequate travel up the ink disc, but that would seem unlikely.

Turn the rollers manually 1/4 turn each in the same direction while they are off the ink disc and see if the uninked area moves — as suggested by HavenPress.

Bob

Another factor may be the number of rollers being used. There seems to be a tendency to use 2 rollers on a 3 roller press, etc. This is a false economy for adequate inking. But all 2 or 3 or 4 rollers having the same lap mark as HavenPress suggests hitting the plate in the same location each impression doesn’t calculate. No mention was made if the plate was rotated, moved, etc to see if the inking problem persisted. I suspect the problem lies with the plate, base, makeready, or something not at all related to flat spots on the rollers.

Have you tried moving the plate in a different direction? I ask because if you flip it, and it’s the same spot on the plate that isn’t inking well, it would mean it’s the plate itself that is giving you issues.

Cassielaine,

You could try manually rotating the rollers on their shafts, slightly, just so you make sure that another part of the roller is inking over that spot, if the less inked spot moves it’s definitely the rollers with a flat spot, which from your photos I’m pretty sure it is, I’ve had that happen before. We managed to finish the job by rotating the rollers every time it came up. You stop the press, rotate them either when they are going up before the disk, or when they are at the bottom.

Best of luck, and let us know if you figure it out!

Thanks all for your answers! I ended up just shifting the plate higher on my base to avoid the spot hitting my plates at all. When I started printing my second color, I started getting a similar spot. I watched the rollers go over the ink disk a few times, and realized there was about an inch where the rollers weren’t touching the disk at the bottom. After reading through some threads about people having similar issues (before I posted this), I remembered seeing something about tapering rail tape. I had 3-4 layers of nylon tape and no tapering, so I cut the tape where the ink disk ends and built up a layer about every half inch until the platen. Voila! Issue fixed, as far as I’ve been able to tell

Thanks again everyone for your help :)

Very glad you were able to sort the issue out, AND that it turned out not to be costly rollers that needed to be addressed!

It’s always nice when it’s just something inexpensive like tape.

Happy printing!

Could it be the packing?

Old packing might have a low spot.