Uneven Inking - No two prints the same - PLEASE HELP!

Hey guys,

I’d love if anyone can offer me some help/advice please!

I can’t for the life of me work out what is going on. I’ve just recently purchased a press - a J.M. Jones Lightning Jobber (pic attached) and I haven’t been able to print more than 1 in a row because it’s inking randomly, unevenly and inconsistently.

I have a boxcar base and am using photopolymer plates.

As per suggestions on other posts, I have tried changing the orientation of the plate, loosening the quoins, taping the rails in 500 different ways, moving the plate to different spots on the base and more.

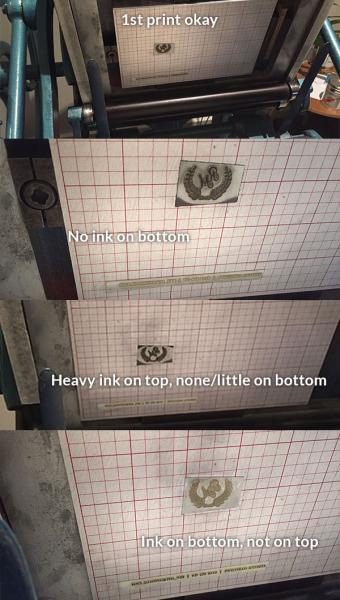

As you can see from the pics, taping the rails in different spots does nothing, because it inks so randomly. At first there is way too much ink on the top of the plate and not enough on the bottom, and then next print there is too much ink at the bottom of the plate and not enough at the top - it’s all over the place!

I should also add that the impression is good and even.

My rollers are new (just got redone by the owner previous to me before I bought it.) The trucks were moving from side to side a little bit on the rails so I put some washers on to pack it out and stop the moving which it has done. I think the trucks on my bottom roller are a bit dodgy though - the left one seems to not roll round (bit of a wobble) - but i’m not sure how to fix it.

P.s I’m in Australia - so any suggestions re getting supplies etc. from NA Graphics / Boxcar Press is difficult and extremely expensive considering our weak dollar :(

I’m not sure what else to add - hopefully I’ve given you enough information.

Thanks so much!

Cass

InkingIssue.jpg

Morgan.jpg

Calm down, this is not as big as a problem as it may seem to be. Forget about the side to side movement of the trucks. What you need to focus on is the truck relation to the size of the roller.

What I would recommend is that you take the roller complete with trucks out of the press and put them on a steel or marble flat to see if the truck is the same size as the roller.

My guess is that the roller is either larger or smaller than the truck and this is why you are having the slur issues.

Hope this helps. Goodnight from Minnesota.

Paul

Hi Paul,

Thanks so much for taking the time to reply and offer advice.

I had a quick look and it seems they are the same size, but tonight I will check on my caesarstone stone bench to see with more detail.

What can I do if they aren’t the same size?

Thanks again!

Cass

I would guess that the rubber roller is either to small or to large according to the truck……what I would suggest is that you put a micrometer or caliper on the rollers and the trucks to determine which is the most consistent.

I am thinking that the rollers are undersized due to wear or over sized due to swelling and this would be the place to start. It may be as simple as buying a new set of rollers.

And the good news is rollers for a C & P are quite easily had with new cores for around $150.00/ea x 3.

Hope this helps

Regards

Paul

That sure is a nice press.

What kind of ink and clean up solvent are you using?

Does the ink disc and rollers have even ink, and the problem is the plate not inking correctly?

Turn your press over by hand. When the rollers go over the plate, watch to see how they touch the plate…are they lightly touching the surface of the image or pressing deeply into the rollers?

Instead of taping your rails, consider taping your trucks instead…if needed.

If the trucks are slipping/not turning evenly make sure the rails are free of oil.

Thanks Paul. I believe my rollers are new but maybe it is best to grab some new ones. I will definitely check the size tonight using the method you suggested.

Thanks Girl with a kluge! He is a beauty, isn’t he!

There is such little information on these guys, I don’t think too many of them still exist.

I’m using mineral spirits, which is what most Aussies use and what I have been told to use for my wash up. We don’t have California wash or anything like that here in Australia.

Yep, it seems the ink disc and the rollers are inking evenly.

It definitely just seems to be the plate that isn’t inking correctly.

I have turned it over by hand to check and since building up the rails with tape, it seems like the rollers are just kissing the plate. The inconsistent inking would suggest otherwise though.

Maybe I should turn it over by hand 3 times again, but take off the other two rollers to see if one roller in particular is pressing too hard (It’s hard to see the second and third roller touching the plate because of the first one blocking a lot of the view)

I have tried taping up my trucks instead, but it seems that my rails are quite low - i would need a silly amount of tape on my trucks which is kinda tricky to keep even when using so much. I might try again tonight anyway and see if that helps things!

Thanks for taking the time to reply, I really appreciate your advice! :)

where abouts in OZ .are you?

The roller diameter should be marginally greater than that of the trucks where you have no taping. When you hand ink type you are pressing on the type and the same should happen on your press.

Taping was the old solution for dealing with gelatine rollers that expanded and contracted with the seasons. These days rollers and trucks should be matched by cutting new trucks for new rollers.

We can reduce one factor straight away by taking off the third roller, you don’t need it and may never need it. Presses were built with 3 roller hooks or a two roller saddle and a hook. For ordinary jobbing work with a light forme only two rollers are needed, for a solid forme or large plates the third roller is put on. Taking it off will save on ink. For very light work you you might get away with one roller.

Heavy inking on the top and bottom edge sounds like the rollers are too low, the roller compresses when it hits the edge of the plate and transfers too much ink.

.

You may have flats on your rollers where they have been left parked on the ink disk for some time. Look along them towards a light and rotate them to see if any flats are obvious.

Check each roller in turn, as the roller comes up after inking your plate turn the roller over while on the press under a light to see if there has been an even ink transfer. Also take the roller off at that point and run the roller over a piece of white card to check the pattern (don’t use paper as it will wrap around the roller)

As well as as taping you have a third adjustment, you can underlay your base. Aim to get an even print first from your rollers and if light raise the base with an underlay adding a very thin sheet of paper at a time.

You may have a combination of problems

Rrodi, I’m in Melbourne, Victoria.

Platenprinter, thanks for the advice. I really appreciate it!

I will remove that 3rd (bottom) roller now and see if that improves the situation at all. I’ll also check for flat spots.

I did read a few suggestions on other posts about adding paper under the base. I must admit I never tried it because I figured that that would end me up with more ink on my plate / base and/or counteract the tape on the rails.

Will report back with my findings!

Thanks again :)

Cass

Hi guys,

Thanks again for all your help!

My rollers are warped and uneven.

I was told they are brand new… But they must have been sitting on the press for goodness knows how long unused and not in the right position.

I’m getting them re-coated here. Fingers crossed the trucks are all good and that re-coating the rollers fixes my issues.

I’ll be sure to report back when they’re done to let you all know how I went (and to bug you again if new rollers doesn’t do the trick ;) )

Thanks again!

Cass

Hi, just a quick tip from an oldie, in Australia the actual plate and mount should be type high which is .918 of an inch, that is the standard hight over here, regardless of which press you are using. Best wishes from Hervey Bay

Hi, just a quick tip from an oldie, in Australia the actual plate and mount should be type high which is .918 of an inch, that is the standard hight over here, regardless of which press you are using. Best wishes from Hervey Bay

Try moving the wonky third roller to the centre position. In the bottom position it may be dragging over the polymer taking the ink off going up and taking more off going down. Regards Bob Mann

Look at the picture highlands print it is a small job.

The 3rd roller is not required, a waste of ink, cleaning material and the printer’s time.

On a 3 roller press you can use 1, 2 or 3 rollers. If you have a single line of type to print use the 3rd roller only. on a light forme use 2 and on a full chase use 3.