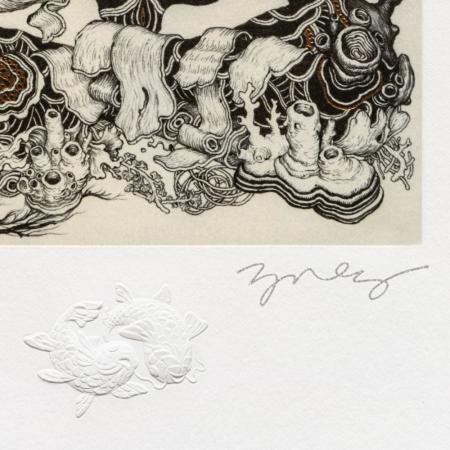

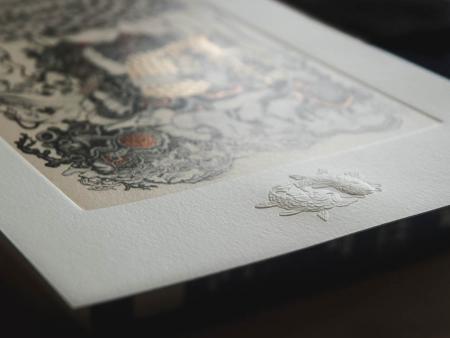

3d sculpted embossing?

Hi folks! I am somewhat new to letterpress and trying to figure out how to do 3d sculptured embossing on giclee prints. Examples attached.

I produce and sell giclee prints for artists, and I’m looking for ways to up my quality game. I’ve seen a few artists release prints with these 3d embossed chop marks, and they always look incredible.

I know you have to have a 3d die made, with a male and female side, and I’ve found a company (metal magic) that produces them, but even they weren’t able to tell me how to use it once I’ve gotten one made!

I have a kelsey 5x8 press, and a Kwikprint 25 hot foil press. I’m hoping I will be able to use one of those to do this successfully. But that being said, I’m willing to get a new machine for this technique if necessary.

Hoping I can get any advice on this process from you pros. If you have done this or know anything about it, from getting dies to working with the machine and setup, I’d love to hear it. Thank you in advance for your time!

jean-pescados-2.jpg

5e125cc25037f1f3334c969678f2c619.jpg

jean-pescados-3.jpg

Unless those embossed images are tiny (meaning 1/2 inch or so) I don’t think you can safely do that with a Kelsey. My suggestion is get yourself a Colt’s Armory or Thompson National press for that kind of work — that’s what they were designed to do.

Bob

Thank you for the reply, Bob! The problem would be the Kelsey is not capable of exerting enough pressure to get a good 3d impression?

I don’t think it would be possible for me to find one of those presses.. I can’t even find any information at all on the Thompson National. Would a more readily available press, like a C&P 10x15, or a Heidelberg Windmill, or Kluge do the job?

Of course If I have to buy a machine I’d like it to be as small and affordable as possible, in addition to being actually locally available, and not too absurdly hard to move (I’ve gotten quotes from machine movers for Windmills in the $800-1500 range).

If I am not mistaken many of the embossed chops are made with machines similar to that of a notary seal embosser. These seal embossers can be purchased at your local office supply store.

Stevegarst, I do not believe these hand-held devices are capable of exerting enough force to do (or even hold the dies of) sculpted 3d embossing. If I am wrong someone let me know! Such a simple option sure would be nice :-)

It may take more production time (registration, squaring up the die to the sheet), but what about a book binder’s nipping press? I’ve seen folk print cuts and the like from those, using blankets and such. Not sure if they would exert enough pressure, but you may be able to find one for a couple hundred or less that could do the trick. I guess you would be limited to embossing only the corners due to press size though.

A second thought would be to contact owosso die makers, they may have some insight on machines that would be good options.

-Cory

The “notary seal embossers” could always create a tremendous embossing, and they could usually handle a round image at least 1” in diameter or maybe a little larger?

The nipping presses have very little impression strength and a ‘floating’ platen. That would be my least favorite option.

Rick

You have three major considerations: pressure enough to make a clean emboss, and a press or machine with a deep enough “throat” to accept the sheet far enough in to place the embossment where you want it, and a machine, press or otherwise, that will accept a sheet as wide as the widest you want to emboss on. The Colts and Thompsons were made in a variety of sizes, I believe 8x12 was the smallest, which would probably be big enough for what you want to do.

You could also do that sort of thing on a C&P platen job press or similar — I would not (repeat not) suggest a press like a Golding Pearl as they aren’t really strong enough for such work.

The seal embossers might be the answer if you can accept that the emboss would have to be probably within an inch of the edge of the sheet. And getting a die and negative made for such a device might be difficult.

Bob

Hi rhinobarkingsparrow, Of the 2 presses that you mention I would suggest that you try the Kwikprint 25. I am not that familiar with this press and I don’t know if it is strong enough to put enough pressure on the die without breaking to give a good image. But it does has the advantage of transferring hand pressure directly to the die so that you can experiment and see if it feels like it stresses the press too much. Also it has heat which is highly desirable for embossing. Having a heated die will make a very nice impression as the fibers of the paper will bend and conform to the shape of the die much better then a cold die.

I could be wrong here but I’m thinking that the die box on this press uses a type high metal die. If that is true then discuss with your die maker there if they can mount your embossing die type high. Then your set up would be to have the die facing down in the die box, the counter afixed directly beneath it on the bed of the press facing up. Your guide pins should be set on the bed of the press (you could use extentions easily on this press to work with larger sheets) so that the sheet faces up.

When you pull to make an impression the hot die should exactly meet the counter below with the sheet in between.

I imagine that (assuming that this press is strong enough) after a little experimenting with heat, trimming and placement of the counter and pressure that you could get very nice embossed prints with the Kwikprint. Also, you might try calling Kwikprint and asking them about the strength and adaptability of the press.

Bruce.

What do you guys think about modifying an automotive arbor press to hold the female die on the arbor and have a table worksurface that holds the male die? Could even attach a heating element onto the female die/arbor to increase the quality of impression.

There’s a guy named Jim McNamara out of Florida that sells the tabletop equipment your looking for.

1 800 370 3739

[email protected]

3628 Berger Rd, Lutz, FL 33548 US

foilstampsolutions.com

His machines can do embossing with a male and female die, and you can do foil stamping to boot. You can buy the manual or automatic, and if you buy the manual and later decide you want the automatic you can later buy the add on.

He also sells type for the machine and can make your dies for you as well.

He’s a really good guy. I’ve been talking to him for a few years and saw his demonstration at the International Print Museum in Torrance last year. A man of wonderful integrity selling a quality product.

I would have the dies made by Metal Magic (so it’s a 3d sculpted brass die) and get one of these embossers.

https://stamptitude.com/collections/embossers

http://www.thestampmaker.com/embossers.aspx

And you are good to go.

Much easier than trying to set it up on a press.

Hi Enriquevw, thanks for the reply. I was told by one of the die manufacturers that you need 3-5 tons of pressure to get a good 3d emboss. There’s no way those hand-held units can do that right?

Thanks Docs Coffee, I’ll look into that. I already have a Kwikprint 25 hot foil stamping machine that is very similar to what they offer though… Perhaps my kwikprint will be able to get the job done?

I doubt there is a lot of experience on here trying to do a male/female emboss using a Kwikprint 25. That is not what it was designed for and you really need to have tried a range of motifs in order to give a quality answer as to its capabilities in that application. A good 3d emboss comes down to the design and paper stock combo just as much as the press.

Unlike the Kwikprint 25, a lot of people here have solid experience with the Kelsey, printing in a variety of size designs on a variety of stocks, so its limits have been demonstrated and are well known. It is not really suitable for basic deep impression beyond soft stocks at small sizes, never mind a lasting 3d embossing.

The Kwikprint however is essentially just a heated arbor press and puts significantly more pressure on a smaller area than the Kelsey, and does so by design. It also doesn’t require dies at type height or any platen adjustment for the stock, since it moves the dies in a straight line for the full range unlike the Kelsey. And as mentioned above, a heated plate helps the embossing a lot, it’ll be much sharper than a cold die.

I say it is worth giving it a shot, you don’t necessarily have to have the pushing die mounted type high, it is enough to clear the mouth of the type holder. Personally, to save on mounting costs I use a 3/4” steel bar cut to fit the type-holder as a mounting base on my Kwikprint 55. I simply mount my magnesium dies to it using a drop or two of super glue and when I’m done stamping a small tap on the side of the die makes it pop right off.

Instead of asking questions about something few if any have tried, just give it a go and start off easy! Get a male/female die pair made, line it up on the Kwikprint, start with a lighter stock and work your way up and you’ll find what stock works well for the 25s capabilities.

Good luck and please share your results.

-Kim

Before getting lost in Tonnage and such, all you want to do is deform some fiber based substrate to create a 3d effect.

There are rules based on skill and expierience:

A cold deform works with small area and bold design.

If you have a larger area or finer detail, heat and dwell is required.

For what we call a Chop to mark a print, manual Seal stampers are fine, before you toss them out the window as you may just know the small, foldable Corporate ones, there are older ones out there.

http://www.ebay.com/itm/Vintage-1920s-Sigwalt-All-Steel-Seal-Stamper-Nor... (example).

If your emboss sits deeper in the sheet than the Throat of the stamper allows, it’s not unusual, as a chop once designed stays as a Pattern, to mount the bottom Die on a hard surface and rebuild the seal stamper to give it a deeper throat and make sure the dies line up.

A Arbor Press sits usually in a Metal frame for support, you would have to restrict your Paper size accordingly.

This type of emboss requires a a male and female die, sculpted Brass dies last the longest.

With a Kwikprint 86, if you mount the bottom die and have the top die in the chase, medium heat and be able to dwell for a minute or so at the same rate of pressure, it should work nicely. Giclee papers are usually softer, so you do not need a huge amount of pressure to deform the substrate, but dwell, heat and a good die.

P1090357.JPG

I have a Kwikprint 25 that was given to me. It’s a fun press but I’ve used it commercially twice in four years for very small runs.

I’m not sure that it will give you the embossing that you’re looking for but I’m not by any means a expert (there are a lot smarter people here on these boards with much more experience than I have), but as Kimaboe suggests it’s a small investment to try it out. A little ingenuity goes a long way!