“halo” /uneven printing with magnesium plate

Hi,

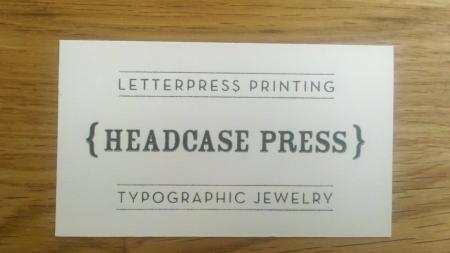

I’m having a problem printing with my new Owosso magnesium plates. The thin lines that I am printing are pulling relatively well, but the larger letters are printing with a blurry sort of halo around them and seem to be inked unevenly. I am using crane 110 lb lettra paper. Any advice would be greatly appreciated. Thanks!

Nicole

hcp card.jpg

Also, I forgot to mention that I am printing on a 8 x 12 New Style C&P. Thanks!

I can’t really see the picture, but my first guess would be too much ink.

Brad.

could be lots of things, make sure your rollers are turning and not sliding over the plate. like brad says too much ink could do this. could be old ink. also could be old rollers, or glazed rollers not accepting the ink. try one thing at a time till you find whats happening. Good Luck Dick G.

Dick, how do you deglaze a roller?

Thanks

Lauri:

Are you going for deep impression? Maybe the ink is being rolled onto the shoulders of the plate. If so, that could indicate your rollers are too low. Taping the rails or using roller bearers should cure that, if that is the problem.

You’re ink also might be too thin, but over inking would be the first thing to look at, then that trucks and rollers are the same diameter.

they sell a deglazing solution, some use putz, i use a van son rapid one step deglazer, its very strong smelling but really cleans the rollers, one other thing, this will only work on rubber rollers, i wouldn’t use it on composition rollers. Good Luck Dcik G.

Hi everyone,

Thanks for all of your help. I’ve tried a few things with not much luck yet, but I’m still working on it! Someone suggested adding magnesium powder to thicken up the ink. Any thoughts?

Thanks,

Nicole

Nicole,

Re: blurring, have you already adjusted/confirmed correct roller height. Also, adding mag will shorten ink but it will also decrease tack. Litho varnish can compensate for this but I’d suggest it’s better not to modify inks if you don’t have to. Good luck solving the problem.

Rod

Nicole:

You might also be experiencing some shifting of the paper during the impression. Make certain the packing on the platen is tight and not buckled. Use as hard a packing as you can, and if possible, use the grippers on the press to hold the sheet down tightly against the platen during impression.

If you can’t bring the grippers in that close, use a rubber band or gripper finger to hold the stock down when printing.

Nicole, maybe the ink is the problem, try a ink you’ve used before and see if it helps. You could also throw it on another press (if you have one) and see if it works. You aren’t too far from me, if you want to try it on my 10x15 c&p. Also you could try bearers on each side of the chase. Good Luck Dick G.

Hi all,

Thanks for the help, I’ve spoken with someone who taught me what I know about letterpress and she suggested it was the magnesium itself. She seemed to think Owosso wasn’t making plates like they used to. I had the thought that maybe it was the wood mounting and I tried with a mag mounting and it worked much better. Too bad the mag mounting is so much more expensive. Perhaps it’s time to switch to polymer!

On another note, I’m about to buy a Heidelberg Windmill and I’d really love to date it. I’ve got the serial number: 45939E any help would be appreciated. Thanks so much! You guys are great!!

Nicolem, get your mag dies unmounted (cheaper to ship) then mount them yourself. As far as dating your windmill. won’t your husband get jealous? Dick G.

Hi all,

Thanks for the help, I’ve spoken with someone who taught me what I know about letterpress and she suggested it was the magnesium itself. She seemed to think Owosso wasn’t making plates like they used to. I had the thought that maybe it was the wood mounting and I tried with a mag mounting and it worked much better. Too bad the mag mounting is so much more expensive. Perhaps it’s time to switch to polymer!

On another note, I’m about to buy a Heidelberg Windmill and I’d really love to date it. I’ve got the serial number: 45939E any help would be appreciated. Thanks so much! You guys are great!!

OOps! I didn’t meant to post that. Dick….ha ha! Well, I don’t have one so I think I’m in the clear. :) I ordered the mag plate mounted on wood as I don’t know how I would have done it myself. The second one I ordered from them already mounted on mag. You said you’re nearby? Where are you located?

Nicole, i’m in Hanson, MA, if you have time you can come by and i’ll show you how i mount my dies, its really easy and you save money on shipping the dies. if you’re buying a windmill there is one in Brockton with a hot plate and foiling attachment, i think he wants $2500 (not positive) the hot plate alone goes for $1000. I have the same foiling attachment on my windmill, you can switch back to printing in only 2 minutes. Call me if you want to come by, i’m here almost all the time, i run a letterpress shop from my garage at home, just don’t try to date either of my windmills, my older one can’t be trusted. 1-781=293=2157. Didn’t you buy a 8x12 c&p from Harding Print in Whitman? Good Luck Dick G.

Dick,

Yes! I did, what a memory. :) How did the renovation of that building go? I remember that he had some beautiful Heidelbergs too but was keeping them. Oh and they were clean and shiny!! The Heidelberg I’m getting is at $1,000. The guy is desperate to move it! Don’t know if you’re looking for more equipment or not, but he’s got a bunch. Thanks for the offer, I may just take you up on it. All joking aside, do you know how to FIND OUT the date of a press? ha ha! Thanks again.

Nicole

Somewhere on this site there is a list of dates for the serial numbers, i can’t remember how to find it. The building is still being worked on, Harding Print moved up the street, the man who runs the windmills worked part time for me back in the 1980’s, he took good care of my equipment, always cleaning something, that is why those windmills look so good. If your windmill has a black ball on the impression it was probably late 40’s to the mid 50’s, the red balls came out i think in the late 50’s thru about 1968, then they came up with the lock outs (you can lock your rollers up on your press so you can die cut without removing them. I.m always looking for equipment, but my wife said something about killing me if anything else comes thru the door so i best pass, i can’t even sneek anything in cause we work together. if you want to learn about windmills i run two almost daily and would be glad to help you, Dick G.

That would be awesome. I’d really appreciate it. The press won’t be in the shop until the weekend of the 9th so I’m just trying to get stuff ready right now. Here’s the monster!

60557_507623527305_108400084_30168973_4098734_n.jpg

i have the same press, mid fifties i think, don’t buy top sheets i’ll share some of mine with you, i use a different system and only use 2 or 3 top sheets a year, see if you can get him to throw in a die cutting jacket, he must have a few hanging around. Make sure you remove the tray in the front under the counter, and the draw under the delivery, those things are expensive to replace. Looks pretty good, little different from a c&p, on a good day i can run 10,000 sheets thru each of my windmills, try that handfeeding. Call anytime, Dick G.

Dick,

Yup, that is my main reason for getting the press. I’ve got a few lines of cards that would be awesome if I could crank out a bunch! Also, I’m teaching classes and I think it will be a draw for students to use a Heidelberg. I would be excited!! Sorry for my ignorance, but why would I want to remove the tray? Won’t I need it? Do you mean only for transport? I’ll see what I can get with the die cutting jacket, I have a line of cards that needs a square cut in them and a die cutter would be soooo amazing. Also, I have a friend of mine who does electrical work helping to wire it into the shop, if I run into some issues would you by any chance be able to do some advising? I would greatly appreciate it. Also, if I could pay you, a little lesson would do me wonders. Thanks so much.

Best,

Nicole

Nicole, the tray and draw will fall out during transport and you will lose a lot of tools for the press. You can call anytime and i’ll help you, if you want to come for a lesson just call first, i’m not cheap, but i will work for coffee and a blueberry muffin. Dick G.

Dick,

Ok, so I went with the polymer plates and a boxcar base to try these business cards again. (I’ll be doing a good amount of polymer printing in the future.) However, I am having the same problem with the blurring. I am now using the VanSon infinity ink. At first I think I put too much ink on, so I took some off and tried again. Not much difference. I also noticed however while taping the rails that it seems like it’s not even. I have everything all set up on the base and when I try to ink it, it will only ink the top half of the polymer plate. I tried taping the rollers halfway and that helped a bit, but I’m still getting the blurring prints. Help!! Also, any advice on how to make it easier to use gauge pins with a boxcar base without smashing them?Thanks in advance.

Best,

Nicole

Nicole, i can set hand type faster than i can type on a computer. you have my number, call me and maybe we can figure it out , if we can’t maybe you can bring your stuff over and try it on one of my presses (thursday is not good) i have 2 windmills, a 10x15 c&p and a 12x18 kluge, one of these should work. Dick G.

I’ve never used a boxcar base, i think you need to lock the base high in the chase, then place the die lower on the base so the gauge pins will clear the base, only problem is this can make you reach too far into the press, very dangerous. i have used a 6 point slug with double sided tape for a gauge pin in a pinch, you can tape a piece of chipboard on top of the slug like a tongue. Dick G.

Hi Dick,

Ok, so I tried all of the things that you said, I taped the trucks and it helped a lot, however the printing is still blurry. I changed papers and the lettra paper wasn’t working as well as the other paper I was using. The prints are still kind of blurry though. I know I should be able to get crisper lines than this. Any other thoughts?

Thanks!

Nicole

Hi Dick,

Question….I asked the gentleman selling the presses son about a die cutting jacket and he wasn’t sure what it looked like, hence if they had any. I did a quick google search and didn’t come up with much in the way of pictures. Do you have a picture or a link you could send me that I could show him? Thanks in advance!

Best,

Nicole

Nicole, the die jacket is a piece of stainless steel that fits on the platten so your dies won’t cut the platten, there might be a picture of it in the parts book or the heidleburg manual. Dick G.

Have you tried different packing?

RREEBB- Yeah, I am either getting a blotchy partial print or a deep impression. Neither of which I want. :(

Hi Nicole,

Try taping your rails. I was having the exact same issue and it work.

Good Luck!

xo,

Dee