Creak/Groan in back of C & P Craftsman

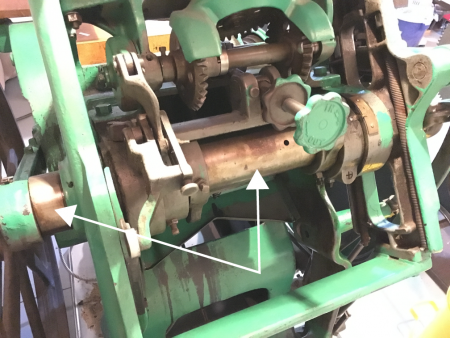

There’s a low groan coming from my C&P 10x15 Craftsman. I’ve tracked it down to the cylinder on the back just under the ink disk (I know I’m not getting the term right, so see attached image). I’ve regularly oiled every oil point covered and uncovered with no improvement. When I turn the press slowly by hand, instead of this cylinder smoothly oscillating, it catches or sizes and releases repeatedly all the way through each forward and reverse motion (as the whole frame moves forward and backward in a single cycle) causing the creak/groan. Any ideas what would make this cylinder seize or catch like this? Another symptom is when adjusting impression with the hand wheel behind the ink disk, turning the wheel has become increasingly difficult as it rotates the same cylinder.

Any help or insight would be greatly appreciated!

IMG_6565.png

oil everything, including the arms. if on the next oiling cycle, there is a point or 2 “That still has oil in it”, then that oil is not penetrating. usually a rubber tipped air nozzle to pressurize that oil point will start things flowing. wear an old shirt and safety glasses. the oil is likely to spray everywhere.

you need to get on this problem quickly, this is the beginning of metal to metal seizure.

I would suggest flooding all the places where that shaft passes through or has other parts pivoting on it, with something like penetrating oil or WD-40, move the press back and forth a small amount (not full cycling, just a bit of movement) to help the penetrating oil penetrate (keeping the bearings flooded), and when things start to free up add a flood of 30ND motor oil to the flood of penetrating oil. The motor oil and penetrating oil will mix gradually and as the motor oil gets into the joints things should free up. The problem is that it sounds as though there is already bearing damage with spalling, due to lack of lubricant, and oil may not be enough — you may have to tear that section down and clean up the spalling to restore full function.

You should also check carefully to be sure the press feet are all in the same plane (level and even) and all frame and other bolts are tight — if the frame is slightly twisted or the roller arms are, that will also cause this problem, which oiling won’t fix.

Bob

Assuming nothing is worn or broken then it seems likely a lubrication issue and you may well be missing a spot and have been for some time which may be causing this event. Suggest that you examine your press closely to find an oil hole that has gone un-lubricated. The cylinder is connected mechanically to the other major parts so the actual issue could be in an adjoining area. It would certainly be easier and cheaper to fiind an oil hole you never noticed before then to start more drastic diagnostic procedures. I see that you moved the press to it’s present location recently? Has it been running normally for some time there? Perhaps an oil cup was removed and not reinstalled during the move? Good Luck

Bruce

Thank you for the wise input!

I’m going to start with checking for a missed oil hole/point, filling the known oil points and see if any refuse to dissipate with a brief cycle, and double check that the whole press is level. If no results, I’ll move on to penetrating oil & the rubber tipped air nozzle to free up any possible clogged oil ports. If I get to this point with no results, I may have to dismantle the assembly to asses any damage. I’m crossing my fingers and hoping it doesn’t require disassembly.

Again, thanks for the insight guys! I’ll post an update once I do some work on it.

Ok, oil seems to be moving freely at all points. I’ve found that I’m missing an oil cover/reservoir next to the impression gauge; there is just an open hole that I’ve been oiling. When inspecting the hole, it looks jammed with gunk and material, but the oil still moves through and after fishing some of it out, it looks like the oil wick material I’ve seen in other oil reservoirs around the machine. Anyway, not convinced this point is the culprit. Working on leveling next.

IMG_7022.PNG

If oiling hasn’t cleared up the problem and it is possible something is out of level, you could try prying up each corner of the base at a time, just a little bit (like with a wrecking bar) and holding it while rotating to press to see if there is any change. One issue is that if I remember right the Craftsman has a one-piece cast iron base frame, which should not warp (though the press is pretty heavy) but if that frame has a minute crack distortion could be your culprit. The bearings are also more precise in tolerances so the least twist could cause your problem.

Bob

corbinw, Your pic looks to correspond with the oil cup on our 10x15 C&P Craftsman. I have included pics showing the 2 holes, one on each side of those bearings for each side of the press. If these holes have not been oiled in some time, that could be it. After you get oil in there work the press back and forth by hand for a while. It might take overnight or longer to loosen up after an extended dry spell. Hope that’s it.

Bruce

oil holes 2.jpg

oil holes 1.jpg

it might also be that something has “got out of square” in its bearings, press may need tightening up and ensuring everything that is horizontal and perpendicular actually is?

this would be a good time to check the pads under the feet of the press. A) is the press level side to side? this can be read directly with a small but good quality level, from the “cylinder” you speak of. this is the back shaft. you should also be able to get to the “main” gear shaft and measure that too. they should be close to them same.

B) are you footing pads level diagonally, is the press “teetering” on opposite feet. this needs to be eliminated whilst preserving level.