About the use of lubricants in Heidelberg 10x15

Hello everyone,

“For the central lubrication system as well as all other lubricating points, use only highest quality, high viscosity lubricating oil with about 10° to 12° E/50°C. Thin oils and greases are unsuitable and should not be used.”

(Manual 13 pages)

Recently need to add new central lubricants, but it seems that few people have used the specifications in the manual?

Will I be able to continue to find the central lubricants specifications that meet the instructions of the manual, or can I choose to use the newer lubricants specifications?

What new lubricants specifications should be used?

thank you all

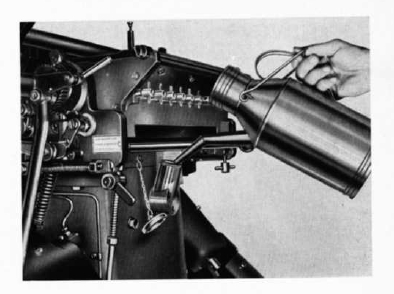

13p.jpg

No need for such complications. Any 30 weight (motor oil) is just fine.

When I first acquired a windmill I spoke to several technicians trying to track down the equivalents of the oils listed in the manual. They equated them to an ISO 150. The equivalent on the SAE scale is SAE 40.

I selected EEZ WAY OIL SAE 40.

i really think that today’s oils and lubricants, especially the synthetics, are far superior to those available at the time this directive was written.(Therefore, at THAT time, a “superior” was probably needed). That said, almost any “LUBRICANT” should be acceptable. just don’t use a “FLUID”. IE: Engine/Gear OIL,,,, Vs Hydraulic/pump FLUID…..the latter, stay away from. i use a synthetic 15-50w engine oil on my kluges and windmill for 5 years now. no bearing failures, and machines turn very easily, and, smoothly.

我可以協助你~在台灣有很多殼牌的品項都改了名稱~可以選用幾款其他的都可:)