So many problems! Where to start?

Hello! I’ve been reading through the discussion boards to see if anyone has had similar problems. Cedarletterpress posted recently with some inking issues. I THINK my problem might be similar but, wanted to get some feedback since I’m just not sure exactly where to start and if I’m having more than one issue to address.

- running an old style 8x10 C&P

- using cranes lettra press paper

- using rubber based van son inks

- the packing consists of 1 piece of press board, 5 sheets of magazine paper and 1 piece of tympan.

- we have and use a lollypop from boxcar press.

- using an aluminum base and polymer plates from boxcar.

- the impression itself seems fine and i would actually prefer it to be a little deeper. though i know it goes against traditional letterpress standards, clients want to see that deep impression.

- ran press w/ no plate for 3 minutes before printing to “work” the ink.

- printing a personalized note card so, there is only a small area being inked and printed.

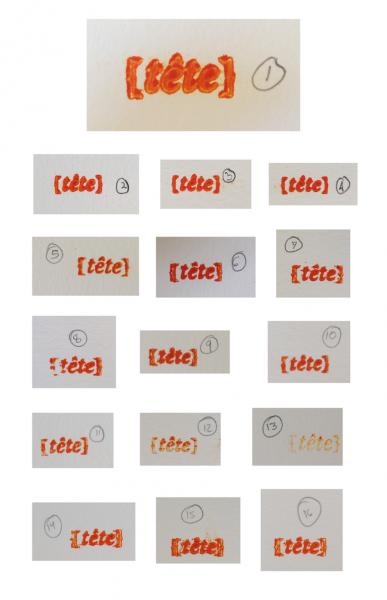

I’ve attached a .jpeg with numbers next to each impression. Below is what we did after certain impressions were made.

after impression #1: added an additional 4 layers of electrical tape to the rails to lift rollers. tested results using lollypop and seem to be getting a good ink strip.

impression #2 —-> #3 —-> #4.

after impression #4: ran press for additional 2 minutes with no plate to work the ink some more.

after impression #5: added an additional gage pin to make sure paper was moving/flopping around.

impression #6 —-> impression #7

after impression #7: added 1 layer of masking tape. electrical tape seems a little thicker and i just wanted to try lifting the rollers just a hair to see it they were over inking the plate.

impression #8… ugh. things are getting worse! —-> impression #9 —-> #10 —-> #11 —-> #12

after impression #12: removed some ink from ink disk in case we had over inked.

after impression #13: removed the layer of masking tape since rollers were no longer hitting the plate at all…

impression #14 —-> #15 —-> #16

after impression #16, we wiped down all 3 rollers, cleaned the plate and ink disk. tried again with a completely different color purchased at a completely different time. however, was still a rubber based van son ink. ran at least another 15 impressions w/ similar results.

sooooooo, is it just my ink? do i just need to add some magnesium carbonate as suggested in other posts? just seems strange since i’ve been printing w/ this same type of ink with other jobs and never had a problem like this.

it’s just so strange since the image is sort of ghosting… or, sometimes it seems like it’s stamping twice. but, again, maybe these are just all signs of “runny” ink and i’m just not sure what to look for?

i also saw that someone mentioned lettra not being a great paper. just bought 200 sheets so, would really like to use it for this job. and, i’ve used it for other jobs anyways and have never had a problem. but, for future reference, are there other papers that people prefer to print with?

would roller bearers help? what do people think about those in general?

is printing such a small amount of type just this hard? i’ve heard some printers say the smaller the amount the type, the more difficult since your rollers have less area to cover… or, something like that.

so, any help/suggestions are greatly appreciated! sorry to write such a long and needy post for my first discussion. :)

thank you!!!

-k

PressProblemsSM.jpg

You need to re-name your photos to get them to show up. I think only alphanumerics, no symbols. Or put ‘em up on Flickr and provide links. Flickr allows for much larger images which makes them easier to examine.

oh, no! i’m sorry… i can see the image on my end but, maybe it didn’t post?

here’s a flickr link.

http://www.flickr.com/photos/kmcelwain/9314192279/

http://www.flickr.com/photos/kmcelwain/9314192279/sizes/o/in/photostream...

thanks!!!

Looks to me like: a lot more ink than necessary; not enough pigment in the ink; excessive roller pressure; possibly rollers skidding on the plate and wiping the ink off the image printing surface onto the sides of the image. Make sure that your roller trucks are the same diameter as the rollers within a few thousandths, and that your lollypop gives you a stripe about 1/8 inch wide or so all over the bed from all rollers. Then ink the plate with one pass without printing, and examine the plate carefully with magnification to see that the entire surface, and none of the sides, of the image area are well inked. If not, no point in hitting the paper until you’ve corrected the inking.

Bob

Read AdLibPress Bob’s last sentence.

No amount of arm waving, cursing or messing with the packing will do any good until the inking is correct. Ink the plate with one pass only. Remove chase and examine with magnifying glass.

thank you so much, bob!

we have a lollypop and were getting the 1/8 inch strip. even tried raising the rollers a touch more but, then they weren’t hitting at all. so, i don’t think we have too much roller pressure.

also, i originally though we were using too much ink. so, after the first few impressions, we remove quite a bit… maybe not enough?

trucks and rollers are close to the same diameter but, will double check to make sure.

when you say, not enough pigment in the ink, what exactly do you mean by that/is this something particular i have done that i should avoid?

the rollers seem to be rolling completely and not slipping but, again, i could be wrong. would this be something that’s easily noticed if they are?

THANK YOU!!!

If your roller and truck diameters are different by more than a couple of thousandths, the roller surface is moving at a different speed than the truck surface, which causes the rollers to wipe the ink across the plate in one direction or the other, depending on which is larger, roller or truck. The result can look on the paper just like what you showed.

The ink on the printing surface (I am assuming a photopolymer plate) appears to be denser in some areas than others, which makes me think you’re using a transparent ink which by definition is either mostly vehicle with a little pigment, or the color is dye. Either one is very fussy about inking system quality.

Bob

You’d be amazed how little ink is required. I’m talking about a very light scrape across the ink disk. Maybe a penny’s worth of ink. It should take you a minute or two for it to spread across the disk and I can still usually see the color of the disk through the ink.

Start with a ridiculously small amount of ink. Less than you think would ever make sense. (They say as much as you would butter on half a slice of toast) Start with less. Less than an 1/8 of a teaspoon then go up from there. That’s a small bit of type, it needs hardly ANY ink.

I feel like I’ve made nearly every mistake in the book already, that looks to me like too much ink being squished out onto the shoulders of the type. I had the same problem for a while. Once it was because I mixed metallic oil based ink and rubber based ink. Don’t fool with changing the chemistry until you tried changing the mechanics.

I love Lettra (there are better papers I’m sure), but don’t toss it. I have no problems printing with it.

This is great! Thank you Bob and Panthera Press!!!

not to be a pain but, back to ink. using victory ink sold by NA graphics. sorry, I misspoke earlier when I said it was van son. mixed autumn orange, PMS 165 with a little bit of pantone yellow. http://order.nagraph.com/ink.html

are these transparent inks?

Would seem like some Red Herrings or wrong Fonts! are entering the equation. From a purely mechanical point of view, (SURELY) up to a point the difference between the thickness of the rollers and the height of the trucks is academic and misleading. The trucks put the rubber/polyeurothene etc the correct height above the type for inking with variations via adjustable bearers and or tape etc. The Roller surface and the Truck during every 360 degree revolution can hardly go out of synchronisation, unless the trucks are slipping. I have 2 machines in front of me now, Adana H.S. No3 and Adana T. P. 48, both of which have rollers and trucks, where the composition is at least 1/8 of an inch less than the trucks, as supplied by our graphic suppliers? Stored away carefully are Thompson British Autoplaten Rollers where the composition is at least 1/4 of an inch less than the trucks! (by design) admittedely with chain driven rollers and built in slipping clutches, within the trucks, and facilities for small diameter steel rider, but never the less, by design big difference between roller and truck size. By implication, the 2 having to be synonymous is possibly misleading? and may lead to the proverbial “wild goose chase”?

I usually start with about 1/8 to 1/4 of a teaspoon of ink (about the size of 2 or 3 peas) on my 7x11 Pearl. I’ll run that in until it’s pretty well spread on the rollers and ink disc and then take a print. It’s much easier to add a little than it is to take some off.

Regarding the roller to truck diameter issue, think about the circumference of each. A roller 1-1/2 inches in diameter has a circumference (the distance it rolls before the same point comes in contact with the type again) of 4.7124 inches. A roller truck that is 1/8 inch larger (1-5/8 inch diameter) has a circumference of 5.06 inches, the distance it rolls before the same point contacts the rails again. That’s 1/3 of an inch difference in distance traveled in one revolution — a difference that has to be made up by the roller or the truck skidding on the type or the rails. Since the trucks generally have a better grip on the rails, the roller will skid, smearing ink along the way. The less difference in diameter the less skidding, with zero skidding with the rollers and trucks the exact same diameter.

Bob

Kate, What are you using for cleaning the plate and rollers?

Seems to me that the ink vehicle has been compromised. Either type wash or oil in the ink.

If that is all you are printing you certainly don’t need three rollers, and might be able to get by with just the single roller. Using masking tape for make-ready is not the best idea, it has a crepe-like surface which can transfer to the impression, plus it is thick which will cause a moulded indentation creating other problems. I see too much ink, too much impression and a transparent ink that, in your attempt to keep up the color makes you flood the form. Add a bit of opaque white to your ink, take off one or two rollers, back-off impression and use the ink very sparingly.

Paul

James, are you saying the ink vehicle has a flat tire???

thanks again everyone for all the help!

when we tried to print this same piece a few weeks ago using only 1 roller. a local printer in town suggested we use all 3 since there is a greater chance for the plate to ink in case one roller is a little off or whatever. not sure if that was advice to follow?

we’re not using masking tape for make readies. just for taping the rails.

the ink was fresh out of the can. but, could still be a bad batch i suppose? however, since we also retried this using just a plain black and got similar results not sure if the ink was “compromised”. we’re in a shop running an a/c but, maybe it’s still too hot and is causing the ink to run? is there a good way to tell if your ink is too thick or too runny? seems thick to me and is obviously not a liquid by any means but, i might not notice if it’s just a little off.

using mineral spirits to clean plate and rollers. is there something better to use. any suggestions more than welcome!

gonna try again tomorrow using much less ink. sounds like the best place to start anyways. :)

Hi Kate_Alter,

I too have been having lots of problems with inking, even using a new tin of VanSon rubber base ink.

I saw you mentioned me earlier in your post so assume you read my post about ‘strange inking phenomena’.

I added this comment today:

So, this afternoon after reading some other forum posts on the matter of inking I tried raising up the rollers by winding electrical tape around the runners. I put on quite a lot so as to lift the rollers completely away from the type, test this by getting a blind impression on the paper even with inked-up rollers and then removing the tape on all four runners bit by bit until I start to get inking.

But alas the problems persist.

Then I read on Happy Dragons Press website that they advocate using Linseed Oil Relief Ink available from Lawrences:

http://www.lawrence.co.uk/acatalog/Lawrence_Relief_Inks.html

I’ve been trying to work with rubber base ink until now for the obvius advantage that it stays open on the press, but it seems to only work well for me on polymer blocks.

So maybe for my lead-type work, which I am doing a lot of at the moment, I need to perhaps try the linseed oil inks.

some thoughts…1/8” is a pretty thick stripe no? I’d aim for thinner. I’d still think you’re using too much ink…and how much time are you waiting after cleaning up with mineral spirits. You talk about wiping down w/ mineral spirits then trying a different ink. How well did you wipe down? I make sure to wipe it down well and wipe with a dry rag and wait at least a few minutes. When there’s still mineral spirits on the plate or rollers, the ink will do crazy things like in your pictures, regardless of how much ink there is or what kind.

I use rubber based inks and find printing with metal type easier than polymer plates.

Math tells me that 1/8” stripe = 2 thou of impression.

I’m not sure how this furthers the discussion, but I did learn about the apothem today.