Making Acrylic / Plexiglas polymer-mounting base

Hello! I am making acrylic Plexiglas bases for mounting photo polymer plates and yielded some satisfactory results. I did a test-run on a sample piece, the result is quite remarkable. So I would like to let the community know before produce the first batch. Please let me know your thoughts on this matter.Any opinion will be greatly appreciated.

Some test run photos attached.

Some advantage of acrylic base:

Juggling with the right size of letterpress printing base? Tired of guess-checking the flatness of the butter-soft aluminium base? Or you just want to make the chase lighter to save your back? The Plexi base is here for you!

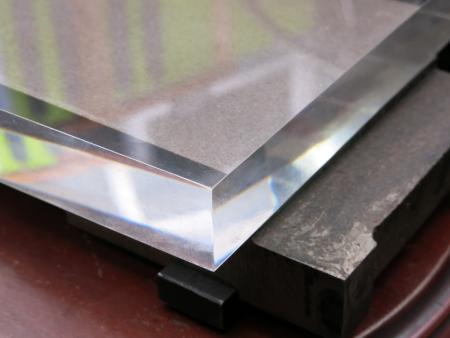

Shine a light through the base then you would instantly notice if there is any dirt at the back of the base, and your can also check if there is any air bubbles trapped in the plate mounting tape.

At least 25% lighter. (It’s a rough guess as I weighted an A5 plexiglas base to a 8x5 inch aluminium base)

Precision grinned to 22.2mm thickness, suitable for TOYOBO KF95 photo-polymer plates.

The only one thing that bugs me is that its surface is much smoother than grind aluminium. Plate mounting tape might peel off if being torn too quickly.

Size Options (thickness 22.2mm):

1 x 34cm

10 x 6.5cm

11.5 x16cm

14 x 19cm

32 x 23cm

These dimensions are suitable for printing a job with a 1up-plate that has crop mark at the corners. For example, 1-up name cards with cropmarks are printed the 10x6.5 cm base (ref. the name card print photo)

Yours,

Thompson

Pressman of Teleportpress, Taipei

I invested quite a great deal in aluminium plates. They are kind of risky, even from named brands.

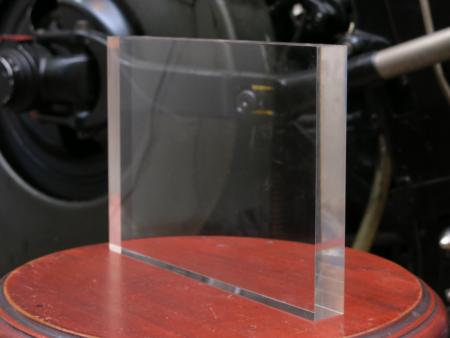

Upright View.

1-up printing namecard on a Heidelberg Windmill. I finesse the roller height until complicated Chinese Characters are printed clearly.

Side view. Pardon my table manner.

The sides are upright so there is no problem during lockup.

I have had success with using acrylic sheet material as a mounting plate for use with photopolymer on top of honeycomb base. You must be somewhat careful with certain solvents as they will “etch” the surface of the acrylic so it no longer is transparent, but certainly will do the job for you.

I, personally have not had any issues with the standard Boxcar or bunting bases I have in my shop, so I use those when I can. When combining type forms and photopolymer, I use the thinner acrylic plates to mount the plates to the aforementioned honeycomb base segments.

John Henry

Cedar Creek Press

Here is a list of the chemical resistance of acrylic material to various chemicals and solvents. Perhaps this could be a guide to what solvents can be used when cleaning.

http://www.eplastics.com/Plastic/plastics_library/Chemical-Resistance-of...

John Henry

Cedar Creek Press

Thanks for the tip, Henry!

I was testing out the base over the week and I find that the base tend to buckle more than aluminium base. I think it will be alright if I dial down the quoins.

A recent recollection that might help with açrylic, we used to put in small wooden dowel pegs into honeycombe base so that you could pin down the plate if required. Also used for putting in a sidelay marker to check registration.

Or you could go onto eBay and buy standard 20mm Delrin or Perspex and underlay with card up to type high as I do and save money.