Ludlow: slug stuck in matrices (help?)

Our Ludlow has been doing some funky things with ejection recently, but very intermittently—dropping a few slugs on the floor before getting to the tray, for example. It’s very [very] cold in the shop which seems to be making everything a little sluggish (…pun slightly intended).

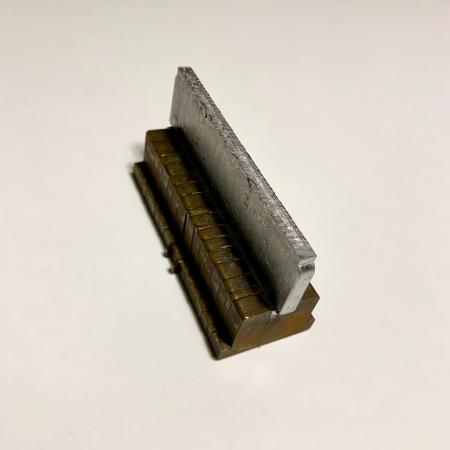

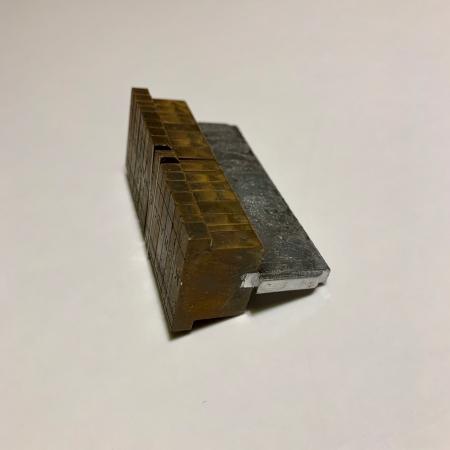

But today the attached happened: a slug full-on getting stuck in the mats and cooling/staying there. We had to unscrew several things just to get the stick out of lock down.

I’m sure this is a common problem that happens for folks, but we’re recent enough to the Ludlow world that every new weird thing is a total novice challenge. With all the info out there I can’t for the life of me find how best to clear these mats out without damaging them and/or causing a giant molten mess.

There’s gotta be a trick. Help?

…and also, any thoughts on why this happened in the first place would be great in terms of where best to focus our cleaning/lubing/head scratching. Thanks!

-Zach

IMG_4170.jpg

IMG_4171.jpg

Well, that’s interesting. I run my Ludlow (model M with external tank and circulating pump) in the cold. The closest I’ve come to your problem is getting my 6 point ejector stuck in a 12 point mold because my plunger was so dirty as to bind in the casting stroke.

Now, looking at your situation begs me to ask if you are running a water pump (Model L) or pump and chiller (Model M). Also would be inclined to ask at what temp your metal is at. Other than that, the only other thing I can think of would be tarnished/dirty mats.

Shop temperature? I was casting at about 35 degrees today. Colder?

Michael Seitz

Missoula Montana

Hi Michael, thanks for scratching your head along with us. Here in Milwaukee it’s about 40 or so in the shop during the day but dips much lower at night. Still, I doubt that’s the problem b/c this machine’s been here, in-house, for decades of Midwestern winters (before my time): I figured I’d mention it just in case. It’s a Model M and I believe there’s antifreeze in the tank…but I’d have to double check with the former owner.

Mat faces aren’t any more tarnished or dirty than average: though, again, they certainly get extremely cold and then go directly into the machine. (But apparently no colder than Montana!)

If you (or anyone!) has thoughts on how to free these mats up again, please share! Certainly don’t want to brute force it. Stay warm Michael! -Zach

I haven’t had that problem (yet!) but, if worse comes to worst, you could try melting the slug with a propane torch….db

What if you dropped it in the pot and then fished out the matrices?

Here is some info that might be helpful.

https://circuitousroot.com/artifice/letters/press/noncompline/ludlow/lit...

I have experienced slugs sticking in the mats. My problem was with particular mats which had been damaged with burrs formed at the surface of the recess within which the character is depressed. When the slug is cast, it is held by these burrs, and is pulled out of the mold, but retained by the line of mats.

I have a mat repair kit which is designed to remedy this issue. A light pass with a fine file is all it takes. To test this solution, try casting using mats which are in better condition.

You can remove the mats from the slug by rocking them back and forth individually until they release, but the slug will not be useable.

John Henry

Cedar Creek Press

Thanks all for your comments, emails and help. Through some tinkering, adjusting and oiling we seemed to have solved the issue for now (*knock wood*).

One likely culprit was that we realized we had a very small leak in one of our mold water lines that apparently had slowly drained the cooling tank—probably over many months (we recently inherited this machine and it was not well maintained prior. Frustrating.) With the amount of water in the tank I’m surprised the former owner wasn’t having issues more frequently! Very low and our glass level-check valve is too fogged up to be usable so no one noticed. Sheesh!

I suspect with little water and a leaky hose the mold wasn’t doing its job well leading to our “sticky” slug problem. We filled ‘er up, patched the hose, slicked up the delivery unit and we’re back in business.

We may just take our stuck slug/mats over to our blacksmith buddies to melt it out if we can’t gently do it… but in the meantime the community’s help with this was great. Thanks so much and happy new year to all! -Zach